Product description 2.2 Operating principle of compressor

Page 22 Operating instructions for S 40-3...S 150-3 series screw compressors

Oil circuit

The oil injected into the air end has the following function:

– It dissipates the compression heat (cooling).

– It seals the gaps between the rotors and between the rotors and the hous-

ing.

– It lubricates the bearings.

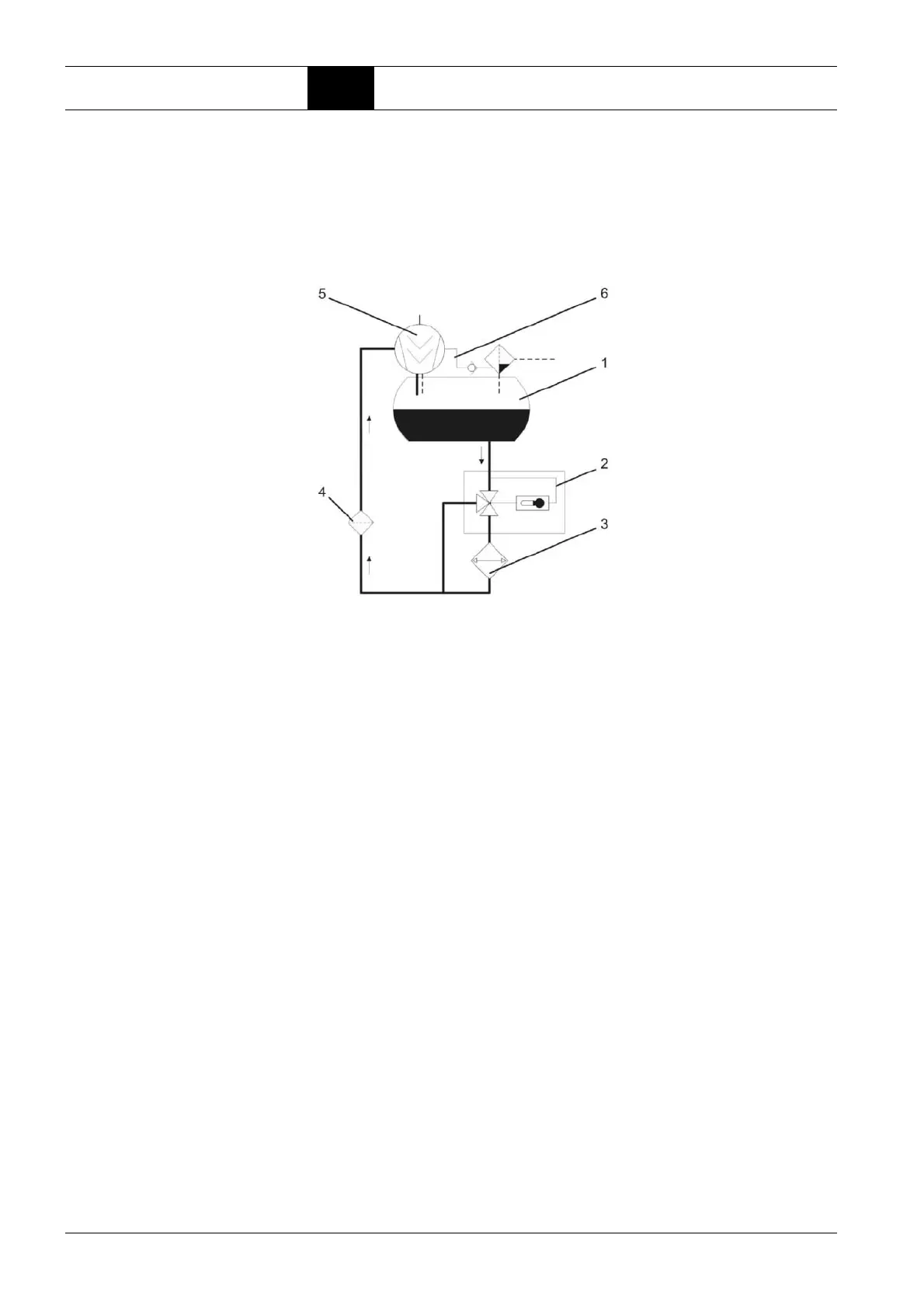

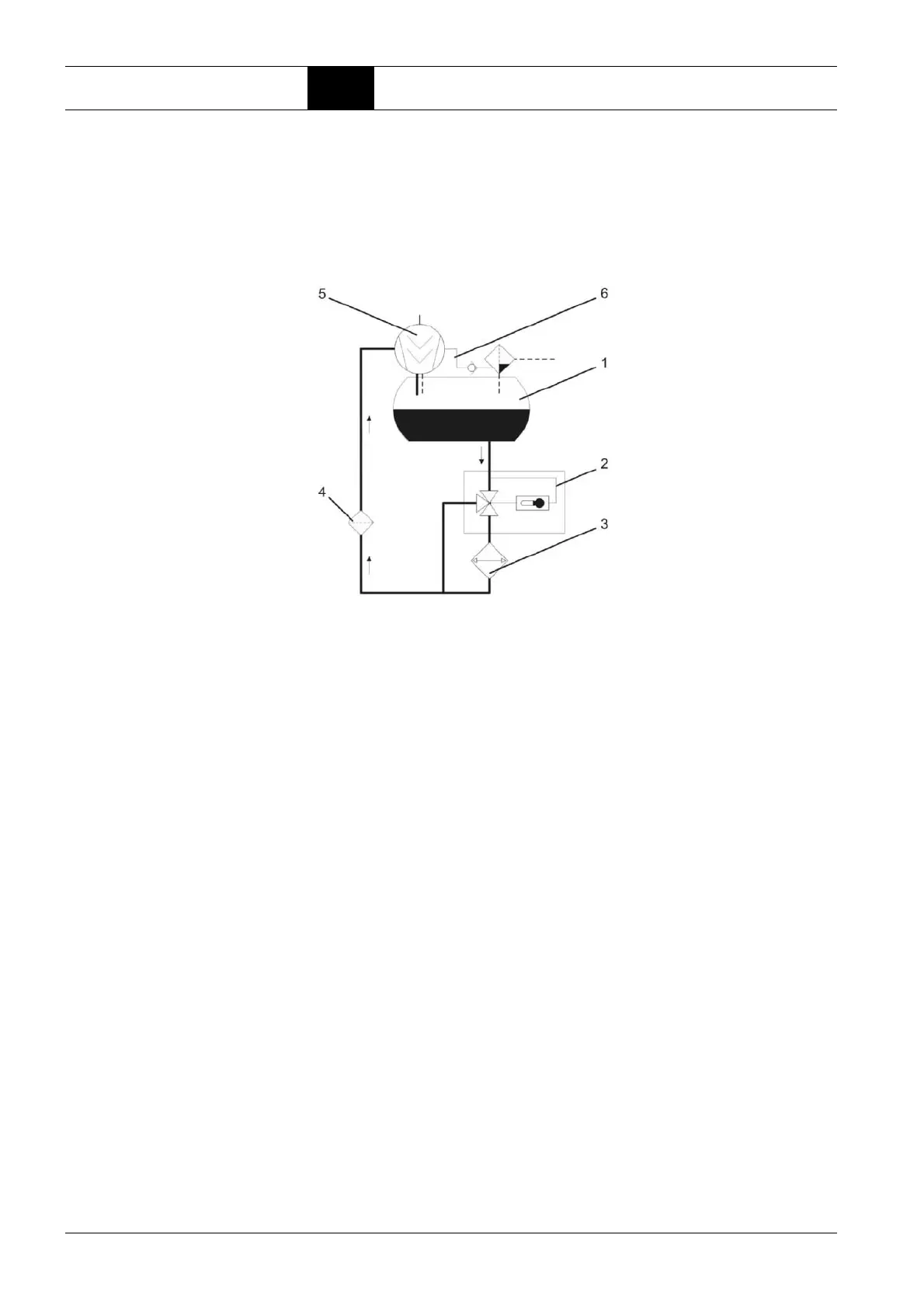

Fig. 2.2: Components of the oil circuit

1 Compressed air-oil vessel

The oil separated from the compressed air through the force of gravity col-

lects in the compressed air-oil vessel. The system pressure forces it out

of the vessel into the air end.

2 Thermostatic oil control valve

Depending on the oil temperature, the thermostatic oil control valve either

allows the oil to pass through the oil cooler or through a bypass (e.g. in

the starting phase).

Thus the oil constantly maintains its optimum operating temperature.

3 Oil cooler (air or water cooled)

The oil cooler cools down the hot oil to operating temperature.

4 Oil filter

The oil filter traps impurities in the oil.

5 Air end

The injected oil returns to the compressed air-oil vessel together with the

compressed air. This is separated through gravity.

6 Drainage line

The air end suctions the residual oil which collects in the oil separator

back into the oil circuit via a drainage line.

Loading...

Loading...