Section 05 ELECTRICAL

Subsection 02 (OVERVIEW)

05-02-3

Magneto Flywheel/Trigger Coil

The magneto flywheel features six protrusions

that are working with the trigger coil. The trigger

coil sends the signals to the MPEM to be pro-

cessed for the ignition system. The MPEM also

uses these signals to accurately calculate the en-

gine RPM and among other things, control the

maximum engine RPM.

Ignition Coil/Spark Plugs

The ignition coil receives its signal from the

MPEM. The ignition coil steps up the input voltage

for the IDI system and the end result is firing of

the spark plugs. It is a double coil that provides a

separate spark to each spark plug. The double con-

trol circuit in the MPEM works separately on each

part of the ignition coil so, one ignition coil still

could work while the other might be defective.

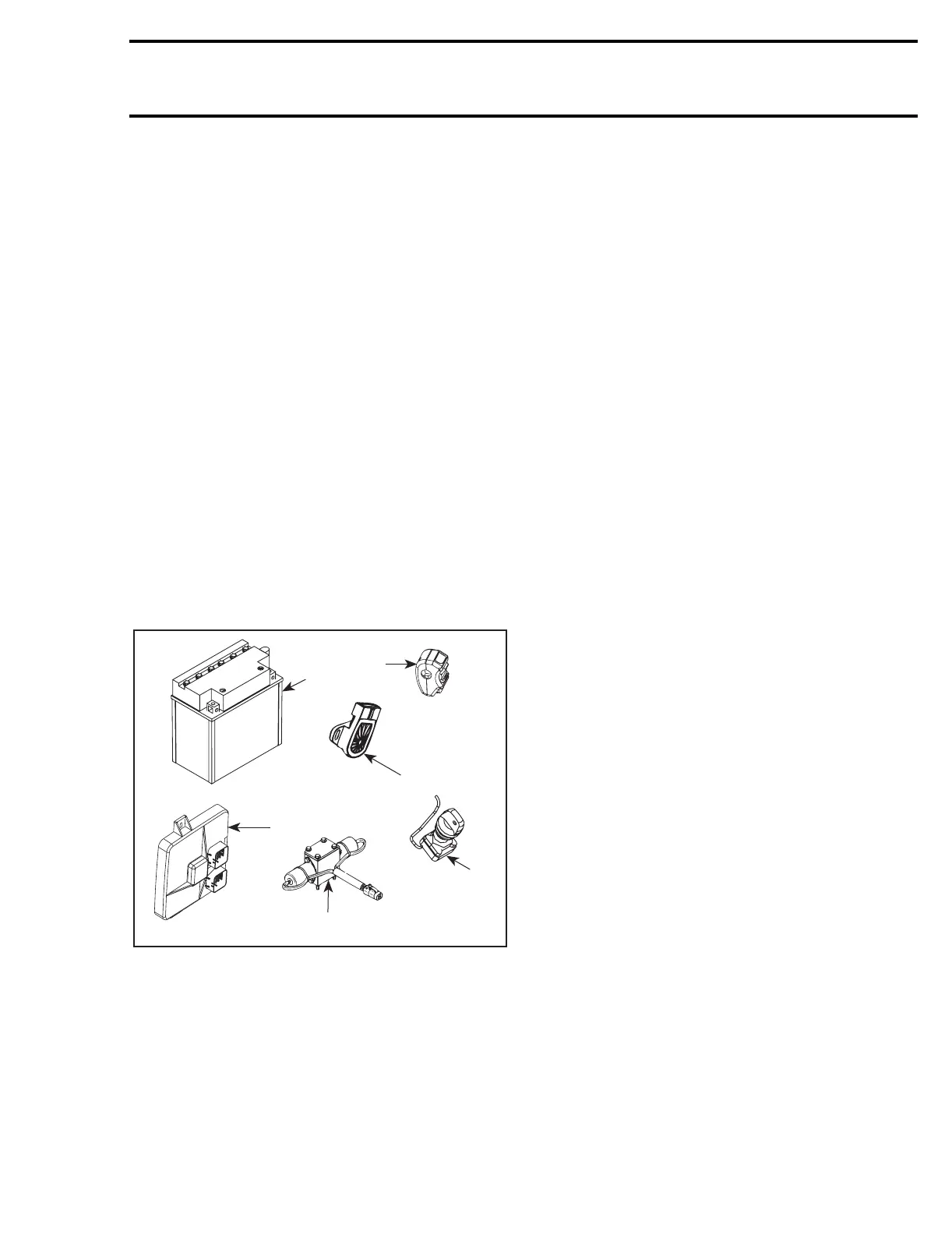

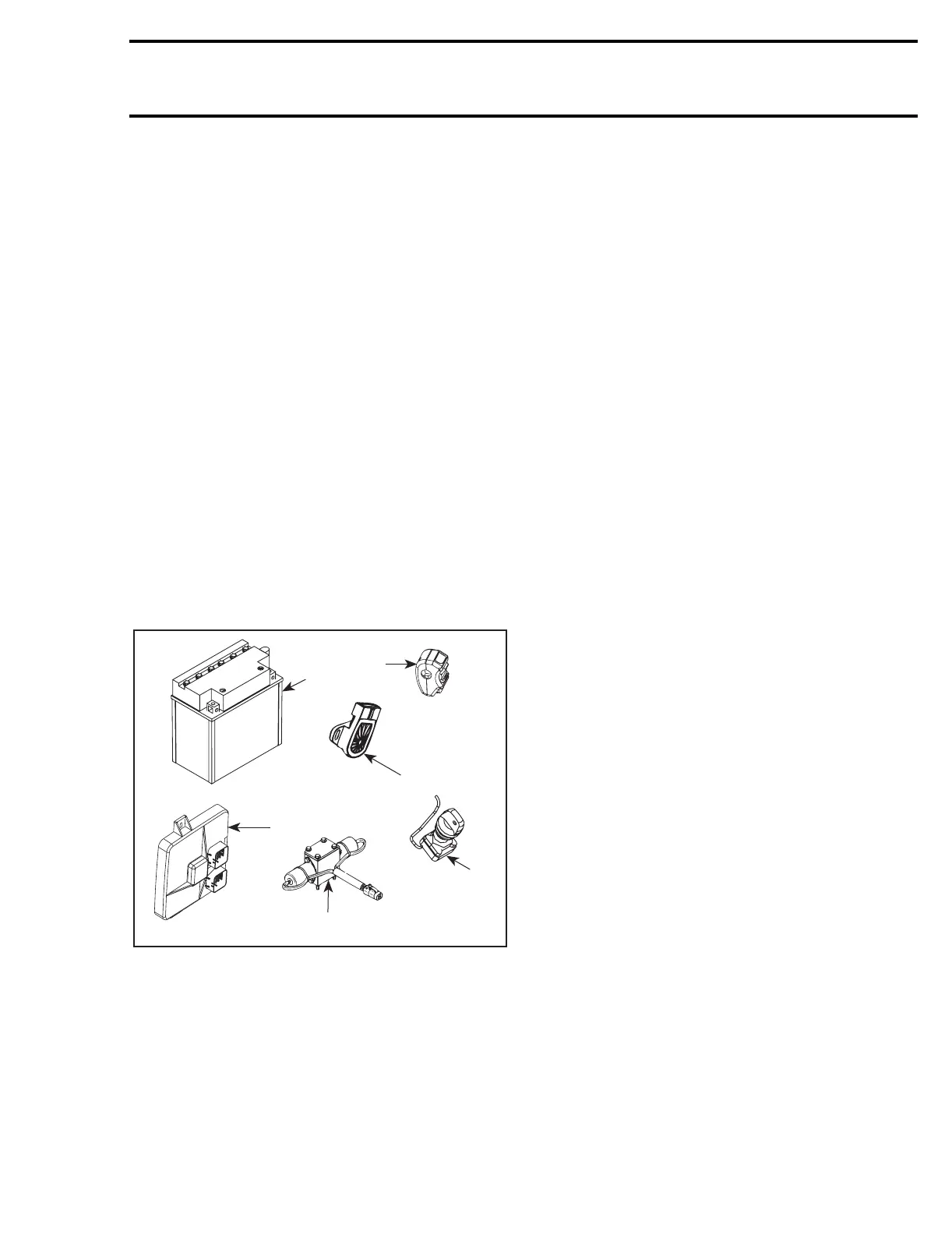

ELECTRIC SHIFT SYSTEM

An electronically controlled hydraulic shift system

is utilized. It is made up of the following compo-

nents:

1. Battery

2. Ignition switch

3. Upshift/downshift switch

4. Sensor

5. MPEM

6. Solenoid/valve

Battery/Ignition Switch

The ignition switch allows battery to supply the

MPEM. The MPEM then supplies the solenoids

for the shifting system.

Upshift/Downshift Switch

When the upshift or downshift button is pressed,

the MPEM activates the proper solenoid (up or

down) that moves the shared hydraulic valve.

Sensor

Many sensors are used to assist the MPEM to ac-

quire the conditions where the vehicle is operated

to allow the MPEM to compute and select the

proper parameters accordingly.

The VSS (vehicle speed sensor) supplies the

MPEM with the vehicle speed.

The GBPS (gearbox position sensor) supplies the

MPEM with the gear position (1, 2, 3, 4, 5).

The STPS (sub-transmission sensor) supplies the

MPEM with the sub-transmission position (P, R, N,

H, L).

The brake light switch is also used by the MPEM

to allow engine starting in other position than

PARK and NEUTRAL.

Other sensors are utilized but they are not related

to the shifting system.

MPEM

The MPEM is responsible to properly engage/

disengage/modulate the clutch and to shift gears.

Although the shift system is performed by hy-

draulic valves on mechanical components, it is

electronically-controlled through the MPEM.

The MPEM uses pre-defined parameters to change

engine RPM, modify the engine timing curve, con-

trol the shift timing and modulation depending on

the sensors reading to accomplish an accurate

shifting adapted to each specific condition.

Solenoid/Valve

The solenoids/valves combo are the electro-hydraulic

devices that actually activate the mechanical oper-

ations. Besides the shifting valve (upshift/downshift),

there is a clutching valve that pushes an actuator

to open and close the clutch and at last, a clutch

modulator valve that regulates the oil pressure to

control the speed at which the clutch is opened

and released (modulation). The hydraulic system

is enclosed in the engine/transmission case and

the same oil as the engine is used for the hydraulic

valves.

GAUGES/ACCESSORIES

The battery supplies the DC current to all accesso-

ries. Some are fed directly by the battery or through

the fuse block and some are fed through the MPEM.

V01G0LA

1

3

4

5

6

2

Loading...

Loading...