Maintenance and repair 41/52

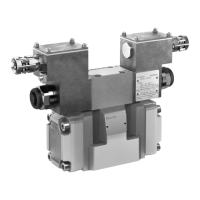

RE24751-XE-B/10.19, H-4WEH...XE..., BoschRexrothAG

10.4 Repair

WARNING

Explosion hazard caused by improper repair!

Improper repair will void the explosion protection!

▶ For repair works, the valve may only be disassembled to the extent described in

these operating instructions.

▶ Defective parts may only be replaced by new, interchangeable components in

original equipment quality.

10.5 Rectifying external leakages

External leakage at the valve connection surface can be rectified on site.

Otherleakages have to be rectified by specialists of the manufacturer.

10.5.1 Rectifying leakage at the valve connection surface

1. Remove the valve, seechapter11 "Disassembly and removal".

2. Inspect the contact surfaces for seal rings at the valve for cleanliness and

damage.

3. Inspect the seal rings and recesses on the connection flanges for cleanliness and

damage.

4. Dry the mounting surface and the contact surface using suitablecleaning

materials.

5. Assemble the new seals.

6. Re-assemble the valve at the contact surface, seechapter7 "Assembly".

10.6 Spare parts

Table 12: Replacement NBR seal kit for the valve connection surface

Valve type Material number

H-4WEH10... R961001132

H-4WEH16... R961001255

H-4WEH25... R961001257

H-4WEH32... R961001259

Table 13: Replacement FKM seal kit for the valve connection surface

Valve type Material number

H-4WEH10...V... R961001131

H-4WEH16...V... R961001256

H-4WEH25...V... R961001258

H-4WEH32...V... R961001260

Ensure the suitability of the sealing materials for the hydraulic fluid used!

See"Datasheet24751-XE".

NBR seal kit for the valve

connection surface

FKM seal kit for the valve

connection surface

Loading...

Loading...