SSB 6720818454 (2016/02) US

Installation | 23

LP conversion kit installation (SSB399 - SSB512)

Natural Gas to LP conversion

The heating unit is factory preset for operating with natural gas. This

set-up can be changed using the conversion kits supplied by the

manufacturer.

NOTICE: This change may only be performed by a qualied

installer or service technician, according to the following

procedure.

Switching from NATURAL GAS to LP

► Close the gas cock

► Disconnect the electric power supply from the boiler

WARNING: to avoid electrical shock, it is mandatory to

disconnect the boiler from the power supply using a service

disconnect external switch.

► Remove the front panel

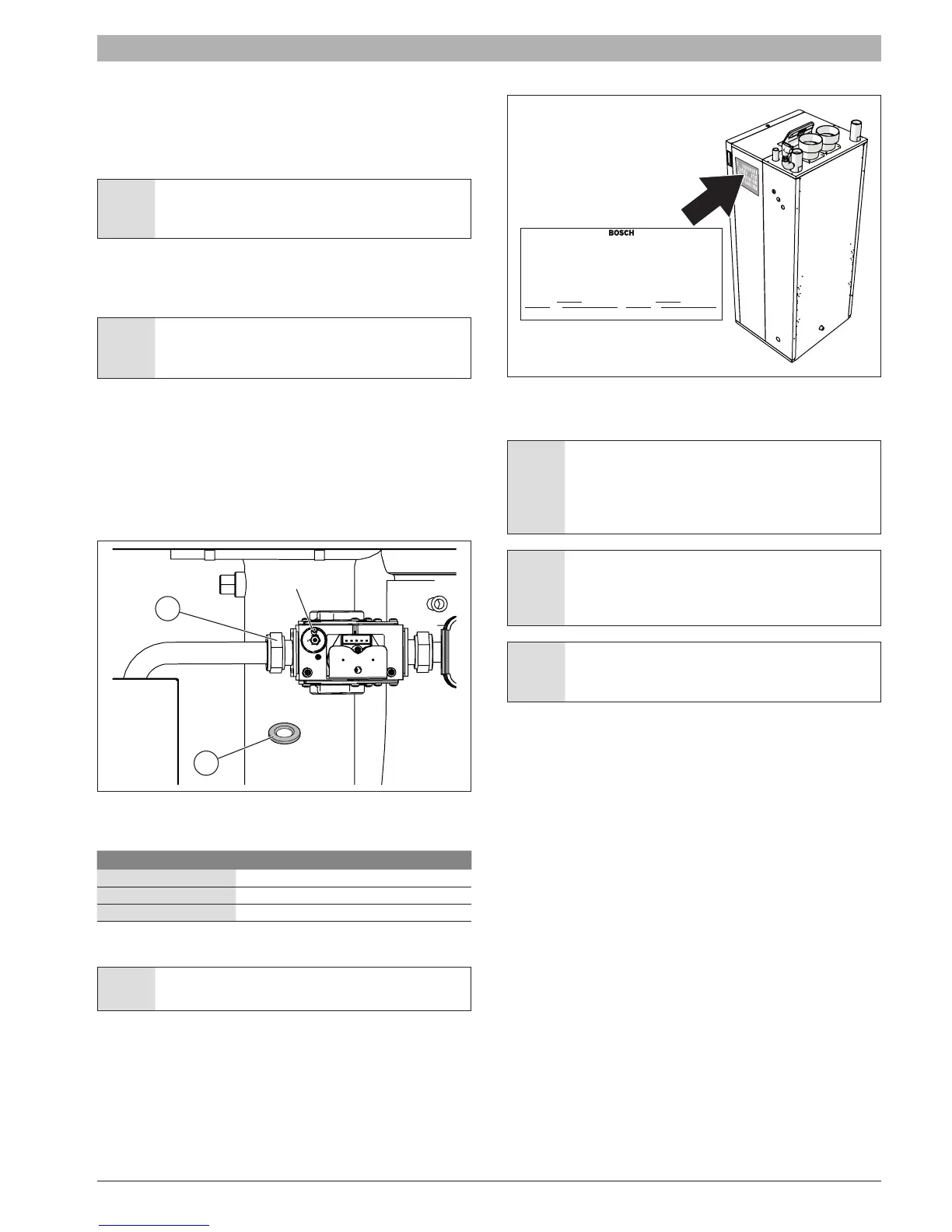

► Unscrew the swivel joint ‘A’ indicated in Fig. 23 to separate the valve

from the connection pipe with the fan

► Separating the two components, you can see the hole where the gas

passes with its gasket

► Place the provided metal orice ‘B’ (Fig. 23) between the two gaskets

► Tighten the swivel joint

► Switch the main power supply to ON

Fig. 23

(*) Balancing tube shown removed for clarity.

Boiler model N° on orice

SSB255 7.0

SSB399 10.5

SSB512 9.5

Tab. 2

F

NOTICE: Make sure there is no demand or call for heat.

► Use the control panel to enter in the parameter list and change the

parameter N° 98 (Gas Type) from “NG” to “LPG”

► Reopen the gas shut-off cock

► Adjust the CO

2

parameter as explained in chapter “5.7 Adjusting

and setting CO2 limits” (see “Tab. 17 Number of turns for gas valve

settings”)

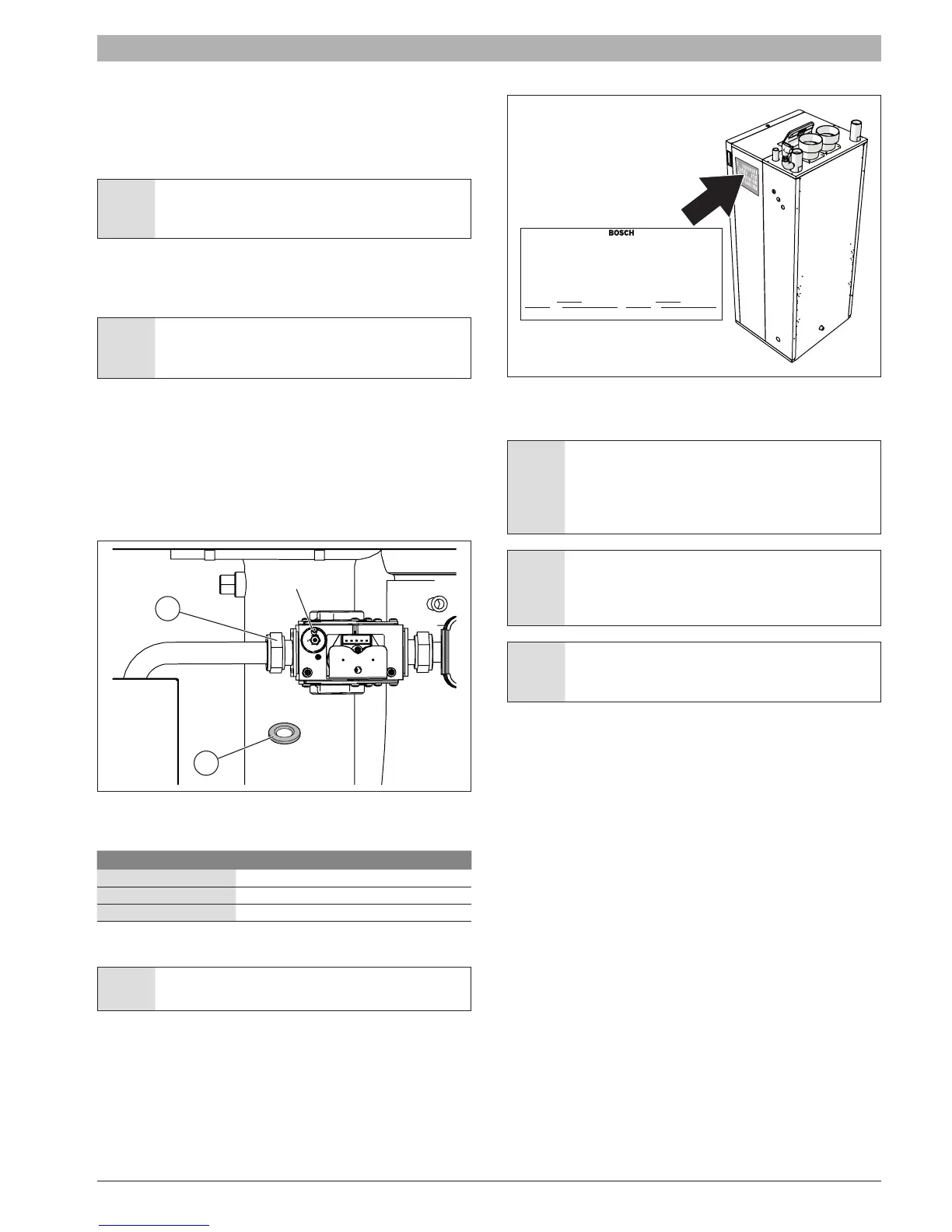

► Afx the gas type label from the gas conversion kit to the appliance

(Fig. 24).

Fig. 24 Afxing the gas type label

4.7 Venting and air piping system

WARNING: Do not connect this gas appliance with any

other appliance unless approved by manufacturer.

Failure to comply with this WARNING could result in the

accumulation of carbon monoxide gas which can cause

severe personal injury or death.

DANGER: The condensate discharge must be lled with

water or combustion gases will enter the room with a risk of

an excessive level of carbon monoxide. For instruction see

par 4.4.6.

NOTICE: DO NOT use PVC for vent piping when using

anti-freeze in the primary circuit of the boiler. Use CPVC, PP

or stainless steel only!.

Make sure that the combustion air is not contaminated by:

• Permanent wave solutions;

• Chlorinated waxes/cleaners;

• Chlorine-based swimming pool chemicals;

• Calcium chloride

• Sodium chloride used for water softening;

• Refrigerant leaks;

• Paint or varnish removers;

• Hydrochloric acid/muriatic acid;

• Cements and glues;

• Antistatic fabric softeners used in clothes dryers;

• Chlorine-type bleaches, detergents, and cleaning solvents found in

household laundry rooms;

• Adhesives used to fasten building products and other similar products.

To prevent contamination do not connect the combustion ait inlet and

exhaust near:

• Dry cleaning/laundry areas and establishments;

• Swimming pools;

• Metal fabrication plants;

• Beauty shops;

• Refrigeration repair shops;

• Photo processing plants;

• Auto body shops;

• Plastic manufacturing plants;

• Furniture renishing areas and establishments;

A

B

(*)

DIRECT VENT BOILER FOR EITHER DIRECT VENT INSTALLATION OR FOR

INSTALLATION USING INDOOR COMBUSTION AIR

CHAUDIÈRE À ÉVENT DIRECT PUT INSTALLATION AVEC ÈVACUATION

DIRECTE OU AVEC AIR COMBURANT

Catégorie

Modèle

Référence

Category

Model

Model no.

IV

SSB-512

7 738 004 896

Converted to LPG (Propane) with conversion kit X XXX XXX XXX

CO

2 (max. rate/ min rate)

Min. inlet gas pressure

Max. inlet gas pressure

Mainfold pressure

Min. input rate

Max. input rate

Output rate

Minimun relief valve capacity

Altitude

10,7/10,3 %

8,0 in.W. C.1,99 kPa

3,23 kPa

30,0 kW

150,0kW

144,0 kW

13,0 in.W. C.

cfactory set - not adjustable

102,360 Btu/hr

511,800 Btu/hr

491,328 Btu/hr

0-2000 ft0-610 m

(Refer to installation instruction for higher altitudes)

This boiler was converted on (day - month - year)

(name and address of organization making this conversion), which accepts

the responsability that this conversion has been properly made.

to gas. By

IV

SSB-512

7 738 004 896

Convertie vers LPG (Propane) a vec le kit de conversion X XXX XXX XXX

CO

2 ( max / min)

Min. pression d’alimentation en gaz

Max. pression d’alimentation en gaz

Pression à la conduite de gaz

Consommation calorifique min.

Consommation calorifique max.

Puissance utile nominal

Capacité minimale de la soupape de sécurité

Altitude

232,1 kg/hr 511,8 lbs/hr

10,7/10,3 %

8,0 in.W. C.

150,0kW

144,0 kW

13,0 in.W. C.

cfactory set - not adjustable

102,360 Btu/hr

511,800 Btu/hr

491,328 Btu/hr

0-2000 ft0-610 m

232,1 kg/hr 511,8 lbs/hr

(Se référ à la notice d’installtion en cas d’altitude plis élevée)

Ce appareil a été converti le (jour- mois- année) en

(nome ed adtrsse de l’organisme effectuant cette conversion), qui accepte la

responsabilité de la bonne execution de cette conversion.

gaz par

X XXX XXX XXX (2015/04)

Loading...

Loading...