32

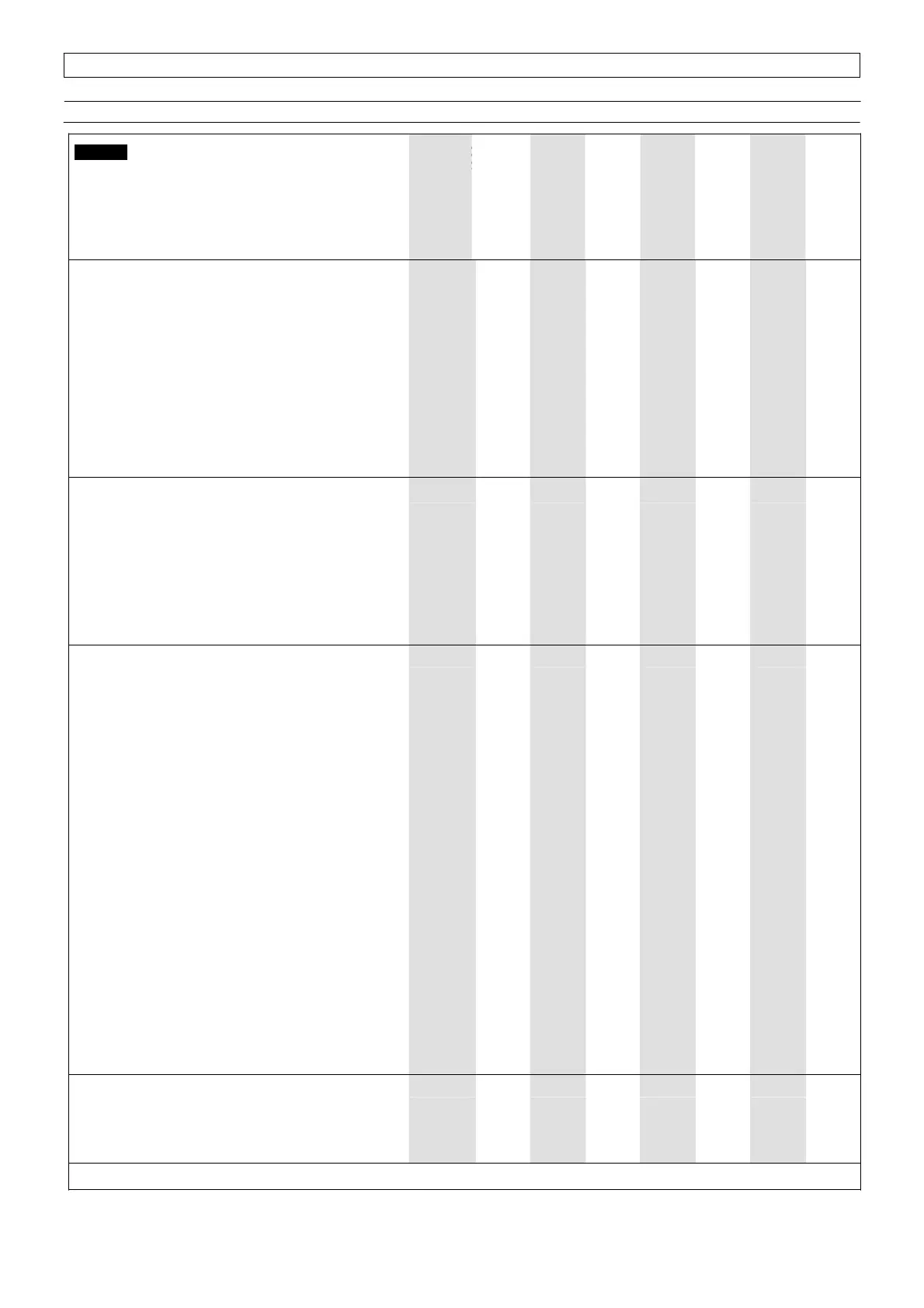

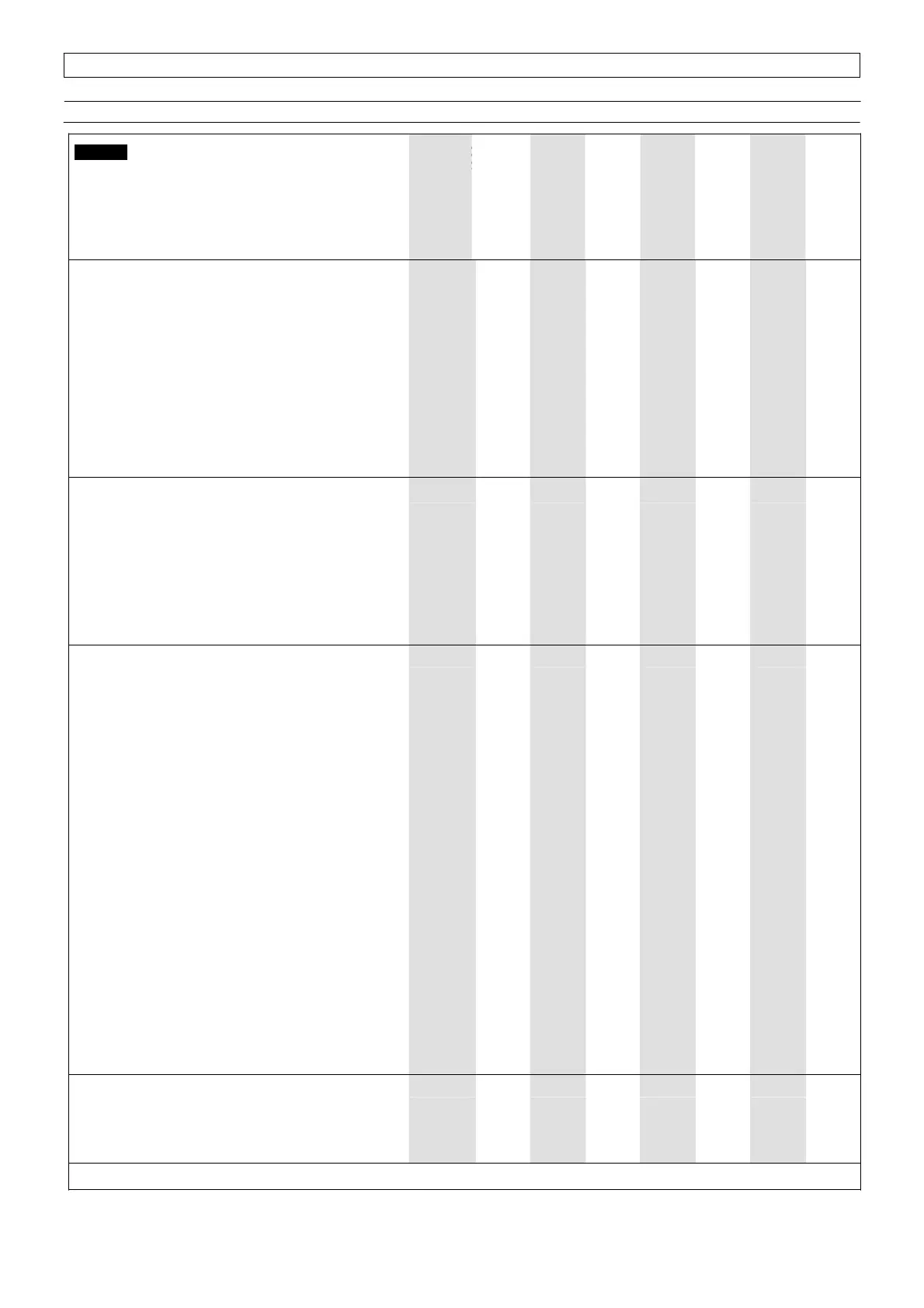

9.5 Compressor maintenance / Maintenance schedule

Danger

Install a "Caution maintenance work" warning

sign and cordon off a wide area around the

workplace before starting any work.

Daily:

Visual checking for external damage, defects and leaks

Check the oil level in the diesel engine

Check the coolant level

Check the oil level in the compressor

Empty fuel water separator (option)

Clean air filter (screw compressor/engine)

between times or renew if the red field appears

Engine maintenance

Note the maintenance indicator

See the engine operating instructions for maintaining the engine

Every 500 h, although at least every 6 months:

Check tyre pressure and wheeluts,

retighten ifecessary

■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■

Adjust brake system (option) or have checked

■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■

Lubricate chassis / draw gear

■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■

Inspect safety valve

■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■

Lubricate hood hinges

■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■

Every 1000 h, although at least each year:

Change air filter (screw compressor/motor)

■ ■ ■ ■ ■ ■ ■ ■

Change oil filter of the screw compressor

■ ■ ■ ■ ■ ■ ■ ■

Oil change (screw compressor)

■ ■ ■ ■ ■ ■ ■ ■

Inspect automatic operational monitoring

■ ■ ■ ■ ■ ■ ■ ■

Change fine separator

every year or if differential pressure > 1bar

■ ■ ■ ■ ■ ■ ■ ■

Check hose lines for damage (leaks, formation of

cracks) and replace, if damaged

■ ■ ■ ■ ■ ■ ■ ■

Clean screen of the suction-off line

■ ■ ■ ■ ■ ■ ■ ■

Inspect control (adjustment/function)

■ ■ ■ ■ ■ ■ ■ ■

Inspect solenoid valves

■ ■ ■ ■ ■ ■ ■ ■

Check the battery acid level

■ ■ ■ ■ ■ ■ ■ ■

Check clamping bolts anduts and retighten,

if necessary (chassis, frame and bodywork)

■ ■ ■ ■ ■ ■ ■ ■

Check suspension components

■ ■ ■ ■ ■ ■ ■ ■

Unscrew optional vessel for tool oil and check inside

for any corrosion. If rust is found, replace the

vessel with aew, original spare part.

■ ■ ■ ■ ■ ■ ■ ■

Every 2000 h, although at least every 2nd year:

Clean cooler (more frequently if used in a dusty

environment)

■ ■ ■ ■

Change coolant

■ ■ ■ ■

■

X For your own benefit, put a cross on the servicing schedule against maintenance work when performed.

Operating hours

60

h

500 h

1. year

1500 h

2000 h

2. year

2500 h

3000 h

3. year

3500 h

4000 h

4. year

4500 h

5000 h

5. year

5500 h

6000 h

6. year

6500 h

7000 h

7. year

7500 h

8000 h

8. year

Loading...

Loading...