51

15.1 Introduction

The user forfeits all rights to claim if

parts other than those of the

manufacturer are used.

We reserve the right to modify design

and performance without prior notice.

Please quote axle number, model and

article number when contacting us with

queries or ordering spare parts.

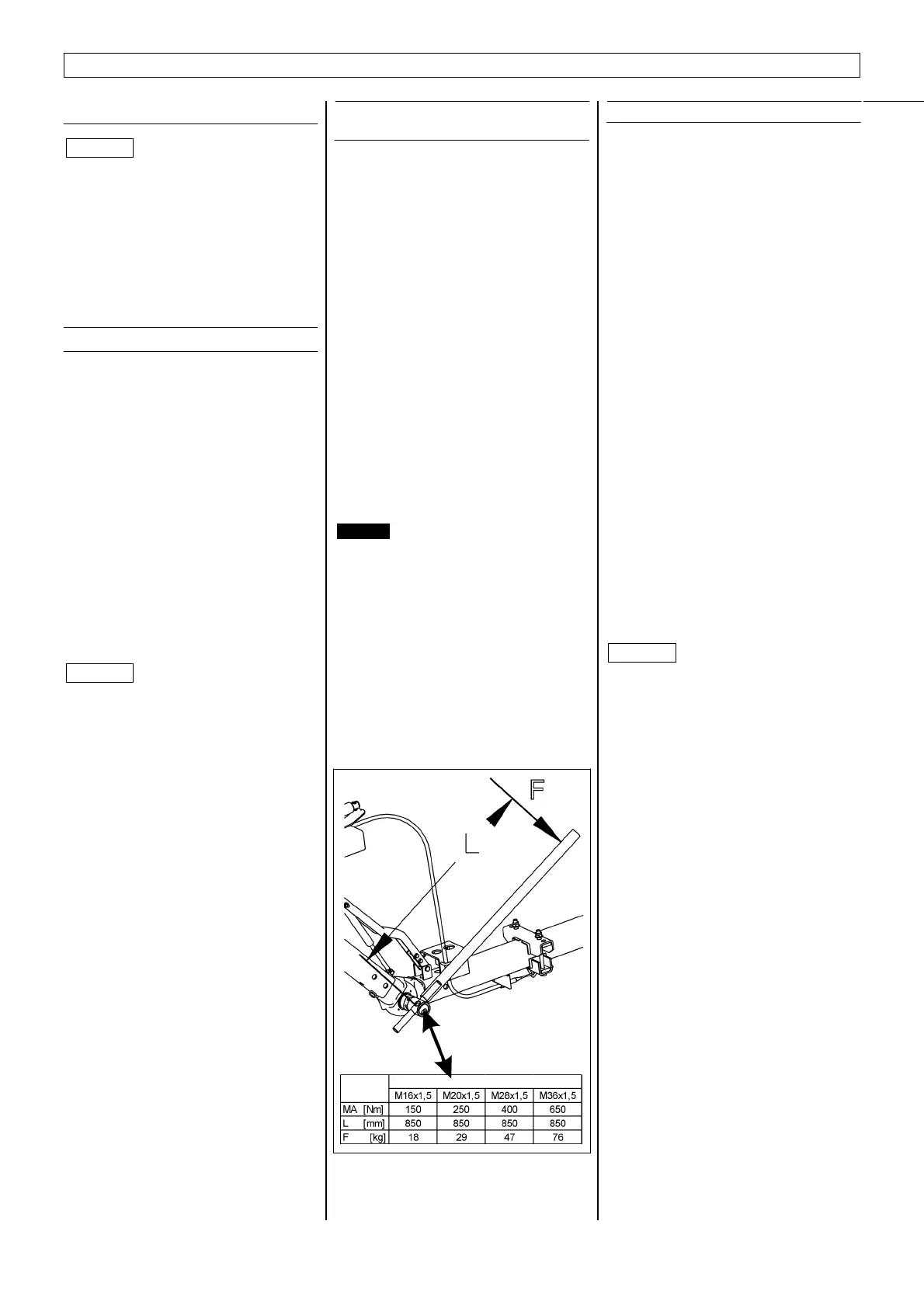

15.3 KHV7,5 height-adjustable

towing system, model B 3.5.13

The adjustable joint between the

drawbar and intermediate arm, and

between the overrun system and

intermediate arm, consists of toothed

heads or retainers with Hirth-type or radial

serrations.

The radial serrations are secured with

fastening screws. The fastening nut must

be tightened to the specified torque in

order to establish a no-play, torque

15.4 Braking system

Introduction

*

KNOTT over-run brake systems consist

of over-run hitches and wheel brakes

used in combination with KNOTT

torsional thrust spring axles. They are

approved in all countries of the EC and

in Switzerland.

*

With the KNOTT autoreverse system

‘Backmat’ there is no problem changing

the direction of travel from forward to

reverse. The braking system is ready

transmitting connection. The tightening

for immediate operation again when

15.2 Safety

*

It is most important that the wheel and

the hub are compatible dimensionally.

This means that the P.C.D., wheel

bolts and inset must all be compatible

both with the hub and the rim.

Particular attention must be paid to the

recommended torque figures for the

wheel bolts.

*

No welding is permitted on the axle.

*

Please note the swing arm movement.

(See assembly instructions).

*

The wheel brakes are matched to the

overrun devices.

Before using an overrun from another

manufacturer, please check the

compatibility with our Technical -

Department.

Model details must not be obscured by

paint now concealed by components.

torque depends on the permitted gross

weight of the trailer and the length of

intermediate (swivelling) arm

Adjusting procedure

After the spring-loaded plugs have been

released from the fastening nuts, the nuts

can be loosened until the teeth are

exposed. The angle of the intermediate

arm can then be adjusted.

Danger

Care must be taken without fail to

ensure that the overrun or towing

system is always aligned parallel with

the drawbar.

The vehicle must not be driven unless

the overrun system is parallel with the

drawbar!

After the coupling has been adjusted for

height, the serrations should be locked

together with the clamping nuts and

secured against working loose by means

of the spring-loaded plugs.

Fig. 49

changing from reverse to forward

travel.

* KNOTT torsional thrust spring axles as

well as rubber spring axles have

superb springing and excellent

dampening characteristics. With the

torsional thrust spring axles the spring

elements with their vulcanized rubber

are pretensioned before being pressed

into the axle tubes. There is no

squashing of the rubber during spring

action. Instead the rubber is stretched

in accordance with its characteristics.

With the rubber spring axles theaxle

tube bears the axle by pretensioned

rubber strings. The results of the

stretching are exceptionally long life

and zero maintenance.

Attention

*

Use the jack only under the fixing

brackets or at the chassis, never in

the centre.

*

Towing eye and ball coupling may

only be changed by specialists.

* Use a new safety nut every time one

of these items is changed.

* Use specified torque setting:

Ball coupling

M12 8.8: T = 77 Nm

Towing eyes

M12 10.9: T = 115 Nm

* When using the ball coupling,

please follow the instructions given.

Attention

Attention

Loading...

Loading...