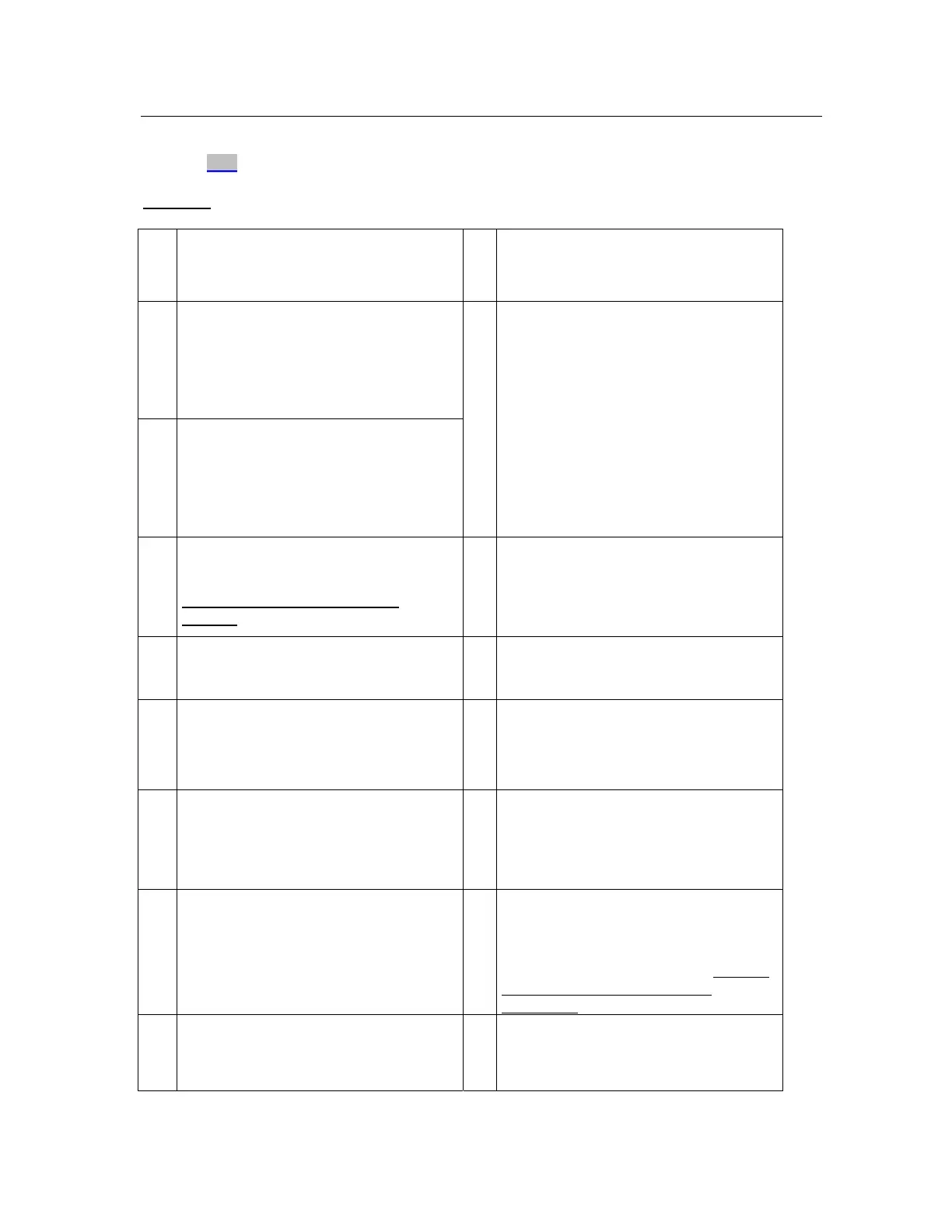

39

11 Maintenance 11

Short description of the maintenance points.

Refer to 11.5 "Maintenance Work Instructions" for exact maintenance sequences.

Machine:

1 Filter:

Perform filter maintenance at 1.5 bar

(21.8 psi) bar pressure (program P39 or

P40).

10 Button trap:

Clean the button trap strainer whenever

it is dirty.

2 Sight-glass, filter circuit:

If there is insufficient clearing of the

solvent, check the filter disc for

damage.

3 Strainer:

Clean monthly (possibly more often

after first startup). Found in the steam

and water feeders.

11 Solvent filling valve:

Open as part of program P44, connect

solvent barrel and filling valve, connect

gas displacement line to connecting

stub on the water separator and fill tank

2 until it overflows and fills tank 1. Refill

solvent punctually. The work tank must

contain at least the amount of solvent

necessary for the high level

P25: approximately 120 l (31.7 US gal);

P30: approximately 150 l (39.6 US gal)

4 Inspection cover for air cooler:

Open semi-annually, remove lint and

deposits with a soft brush and water.

Do not use steam jet: danger of

bursting

12 Process water collecting tank:

Dispose of process water in

accordance with regulations. Do not

allow to overflow!

5 Drying controller DRYSTAT:

Check for dirt.

13 Safety separator drain

You can completely drain the safety

separator when needed.

6 Compressed air drain:

Drain water weekly at the valve of the

glass tank.

14 Process water drain valve

Drain for process water purification or

disposal when the liquid level is at the

mark in the upper third of the sight-

glass.

7 Insertion filter

Clean insertion filter after 8 to 10

cycles, more often in case of heavy

linting. Clean mat in the machine

weekly.

15 Sight-glass, safety separator:

Remove and clean sight-glass when it

is dirty.

8 Grease nipple, fan:

For monthly lubrication of the fan shaft

gasket

16 Still rake-out door:

Strip still daily or after filter drain with

program P36. Empty tank only when it

is cool. Scratch out any residues. Close

door again firmly. Leak check. Dispose

of residues in accordance with

regulations.

9 Grease nipple, cage:

For monthly lubrication of the cage

bearing.

17 Drain valve, water separator:

Weekly, water separator

P25/P30

Loading...

Loading...