41

11 Maintenance 11

11.3 Summary of the Maintenance Programs 11.3

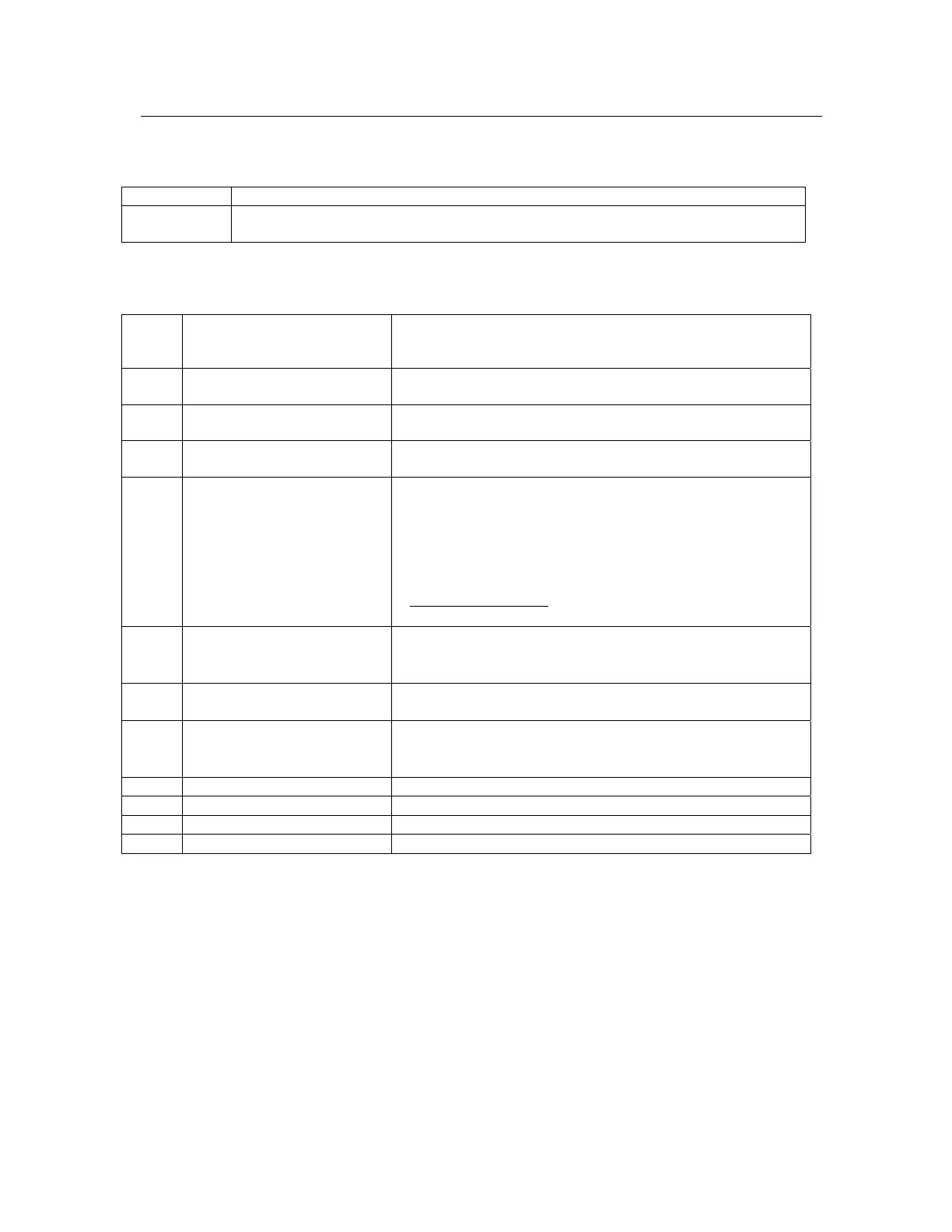

P17 to P33 Free programming locations

P34

Deodorizing: Attention: Always select this if the loading door cannot

be opened.

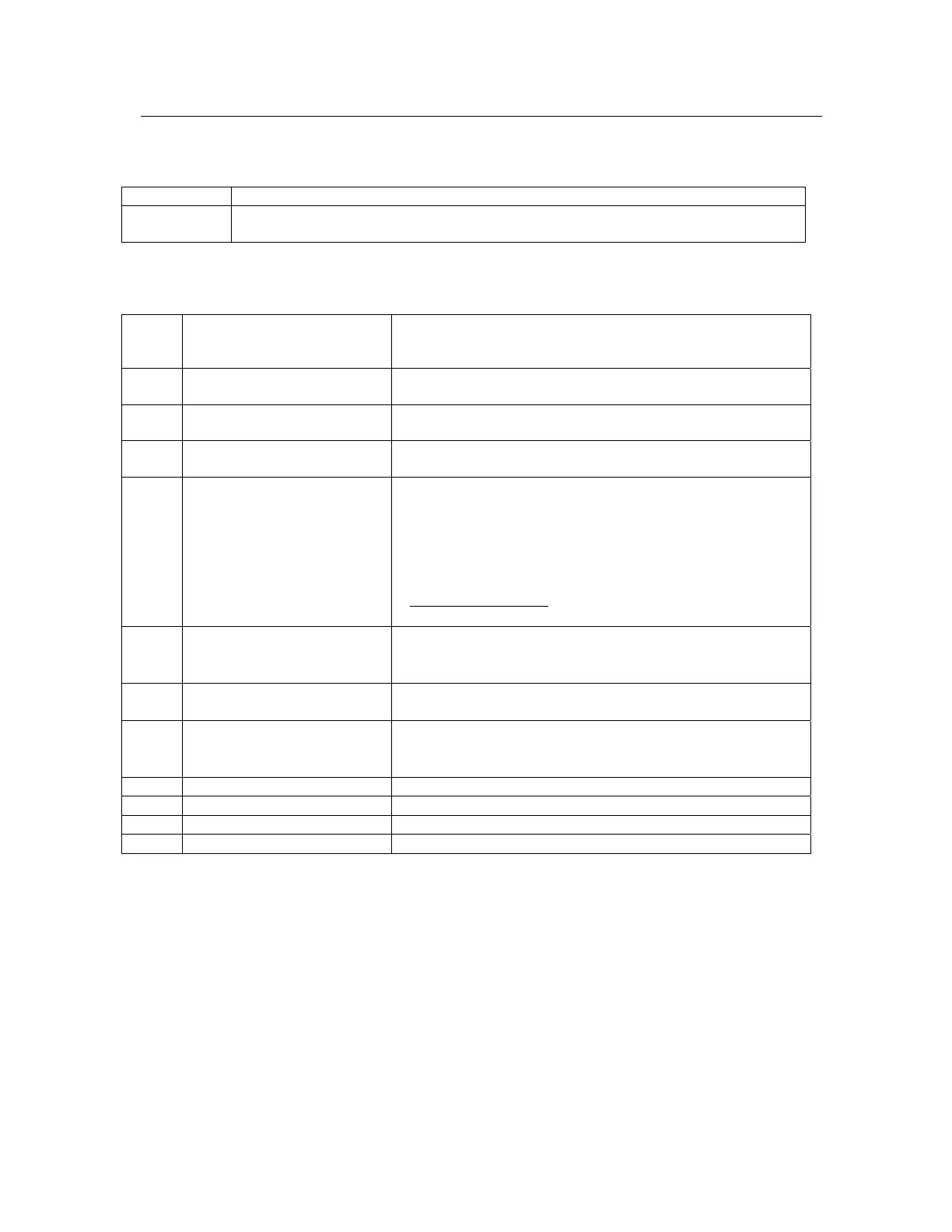

The following maintenance programs are installed in the P25/P30

P35 Prepare stock solution Addition of drycleaning detergent in the work tank solvent

by preparation in the pump circuit, with dosing via the

dosing unit (manual operation); then drying with reduction

P36 Distillation maintenance Still stripping and subsequent reduction or program

sequence "emission-free still rake out"

P37 Transfer pumping of

distillation residues

(only with emission-free still rake out system)

P38 Pump out distillation

residues

(only with emission-free still rake out system)

P39 /

P40

Filter maintenance Start of automatic filter maintenance program with spinning

and simultaneous 50% draining to the still. Then additional

spinning and complete emptying into the still. Finally, filter

circuit and, if filter powder is used, precoating with the filter

powder. Pumping to work tank and spin to still with

subsequent drying and reduction.

If filter powder is used

, fill the bag that comes with the

machine and put it in the cage before the start.

P41 Slimsorba maintenance

(only on machines with

Slimsorba)

For desorption of the Slimsorba at times other than during

the cleaning cycles. The program has two phases:

desorption and carbon cool-down.

P42 Rinse SPRAYMATIC SPRAYMATIC is rinsed with solvent and then dried with

reduction.

P43 Rinse back wall of cage Pump from work tank for rinsing and spinning the cage

with solvent. Then pump to distillation, followed by drying

with reductions.

P44 Fill tanks Fill the clean tank, then overflow into the work tank

P45 Empty tank 1 For pumping out the work tank. Empty the machine

P46 Empty tank 2 For pumping out the clean tank. Empty the machine

P47 Empty tank 3 For pumping out tank 3. Empty the machine

P25/P30

Loading...

Loading...