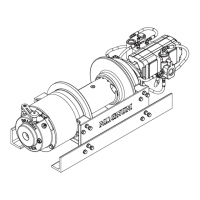

What to do if my BRADEN CH150A Winches hoist won't lower the load?

- SSamantha ShawOct 30, 2025

If your BRADEN Winches hoist is not lowering the load or not lowering it smoothly, here are a few potential causes and solutions: * A plugged pilot orifice in the brake valve could be the issue. To resolve this, remove the pilot hose and fitting from the brake valve, then use a 5/32 in. hex wrench to remove the pilot orifice. Clean the orifice (its diameter is approximately .020 in. (0.5 mm)) and reinstall it tightly, or install a new orifice plug into the brake valve port. * A defective brake cylinder seal may be preventing the static friction brake from releasing. Check the brake cylinder seal by disconnecting the swivel tee from the brake release port, connecting a hand pump with a 0-2000 PSI (0-13,800 kPa) pressure gauge and shut-off valve to the -4 JIC fitting in the brake relea...