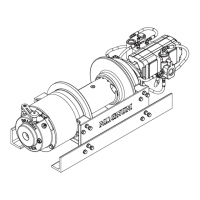

Why does my BRADEN Industrial Electrical winch run hot?

- CChristopher WilliamsAug 4, 2025

If your BRADEN Industrial Electrical winch is running hot, it could be due to several factors. It might be mounted on an uneven or flexible surface, causing distortion and binding of the gear train. Ensure the mounting surface is reinforced and level the winch with shims if needed. Also, ensure that the hydraulic system temperature is not more than 180 degrees F, thoroughly clean the exterior and flush the interior. Excessively worn or damaged internal winch parts can also cause overheating. Disassemble the winch to inspect and replace any worn parts.