Brent 1082/882 — Maintenance

4-25(July 2014)

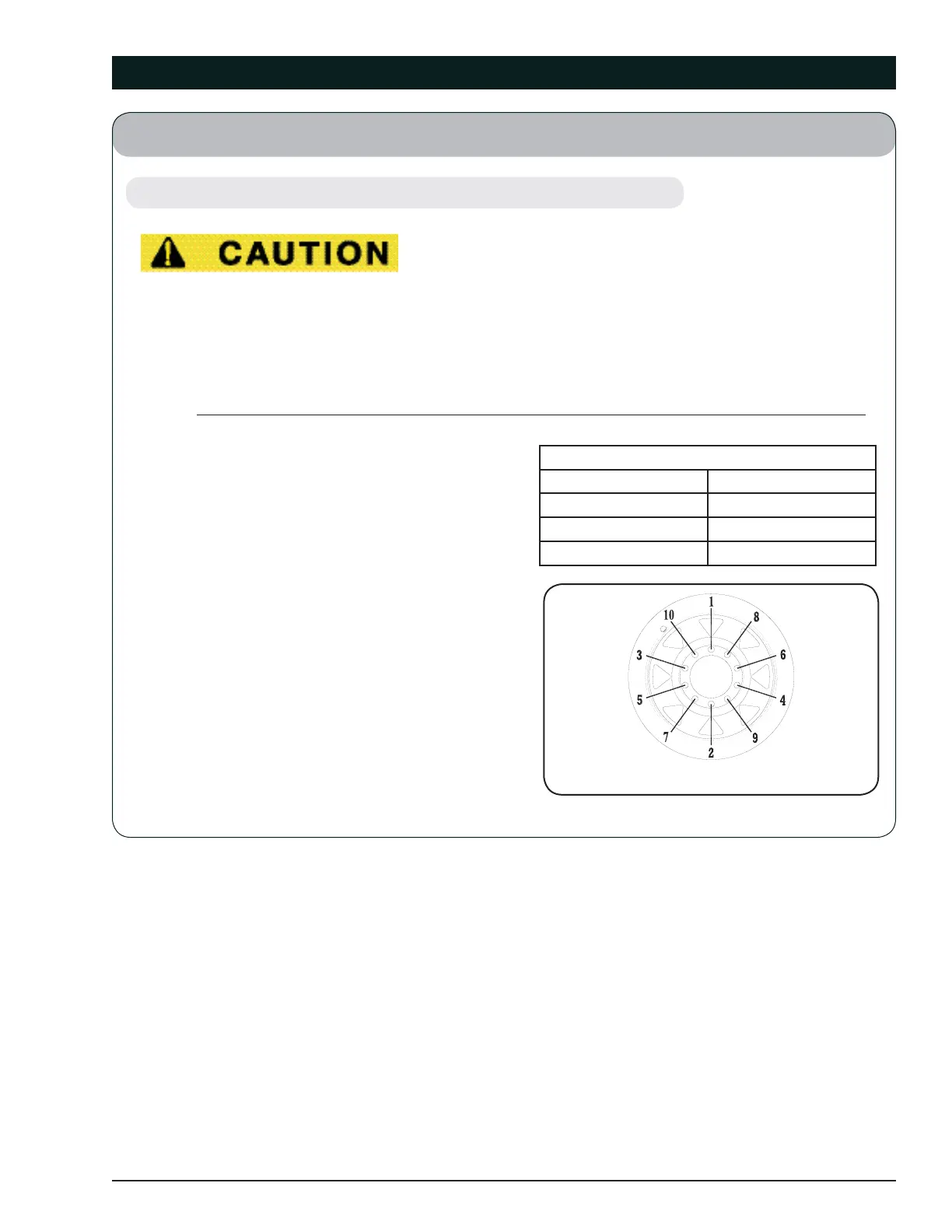

DIAGRAM 1

10 BOLT

Wheels and Tires

WHEEL HARDWARE

SIZE FOOT-POUNDS

3/4-16 (UNF) 365 ft.-lbs.

7/8-14 (UNF) 440 ft.-lbs.

M22x1.5 475 ft.-lbs.

Wheel Nut Torque Requirements

• IMPROPERLY TORQUED WHEEL NUTS/BOLTS CAN CAUSE A LOSS OF IMPLEMENT

CONTROL AND MACHINE DAMAGE. TORQUE WHEEL NUTS/BOLTS TO VALUES IN

TABLE. CHECK TORQUE BEFORE USE, AFTER ONE HOUR OF UNLOADED USE OR

AFTER FIRST LOAD, AND EACH LOAD UNTIL WHEEL NUTS/BOLTS MAINTAIN TORQUE

VALUE. CHECK TORQUE EVERY 10 HOURS OF USE THERE-AFTER. AFTER EACH

WHEEL REMOVAL START TORQUE PROCESS FROM BEGINNING. WARRANTY DOES

NOT COVER FAILURES CAUSED BY IMPROPERLY TORQUED WHEEL NUTS/BOLTS.

Failure to check torque before fi rst load may dam-

age wheel nut/bolt seats. Once seats are dam-

aged, it will become impossible to keep nuts/bolts

tight. Tighten nuts/bolts to applicable torque value

shown in table. Start all nuts/bolts by hand to pre-

vent cross threading. Torque nuts/bolts in the rec-

ommended sequence as shown in Diagram 1.

Loading...

Loading...