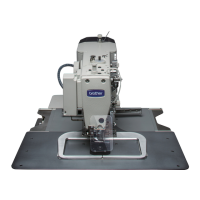

Why does the upper thread keep breaking on my Brother BAS-341F?

- LLisa LewisAug 19, 2025

If the upper thread breaks on your Brother Sewing Machine, several factors could be at play. The upper thread tension might be too strong, requiring adjustment. Ensure the needle is correctly installed with the groove facing forward. The thread might be too thick for the needle; use the correct thread. Check and adjust the tension and height of the thread take-up spring. Inspect for any damage or burrs on the shuttle hook, needle hole plate, or needle, and file smooth or replace if necessary. If using synthetic thread, melting could be the issue, so use a thread cooling device. Finally, ensure the thread is correctly passed along the thread path.