4.4.22 TTroroububleleshshooootinting fog for Par Papeper Fer Feededining Prg Proboblelemsms

End users can solve problems related to paper feeding as long as they follow the User CheckEnd users can solve problems related to paper feeding as long as they follow the User Check

items.items.

If the problem still cannot be solved, implement each procedure according to the stepIf the problem still cannot be solved, implement each procedure according to the step

numbers in the numbers in the tables below.tables below.

4.2.14.2.1 No pNo paper aper is fis fed fed from rom the pthe paper aper traytray..

4.4.2.2.22 PaPapeper ber becocomemes wris wrinknkleledd

<User Check><User Check>

-- Check that the papCheck that the paper is set in the paper tray correctler is set in the paper tray correctlyy..

-- Check thaCheck that there is not too much pt there is not too much paper set in the paaper set in the paper trayper tray..

-- Flip over the paper in the papeFlip over the paper in the paper tray or rotate the paper 180 degrr tray or rotate the paper 180 degrees.ees.

-- Check that the thicCheck that the thickness of the paper is withkness of the paper is within the standain the standard.rd.

-- Check thaCheck that the size of the papet the size of the paper is within the str is within the standardandard..

-- Flip throuFlip through the paper angh the paper and reset it in the paper trd reset it in the paper trayay..

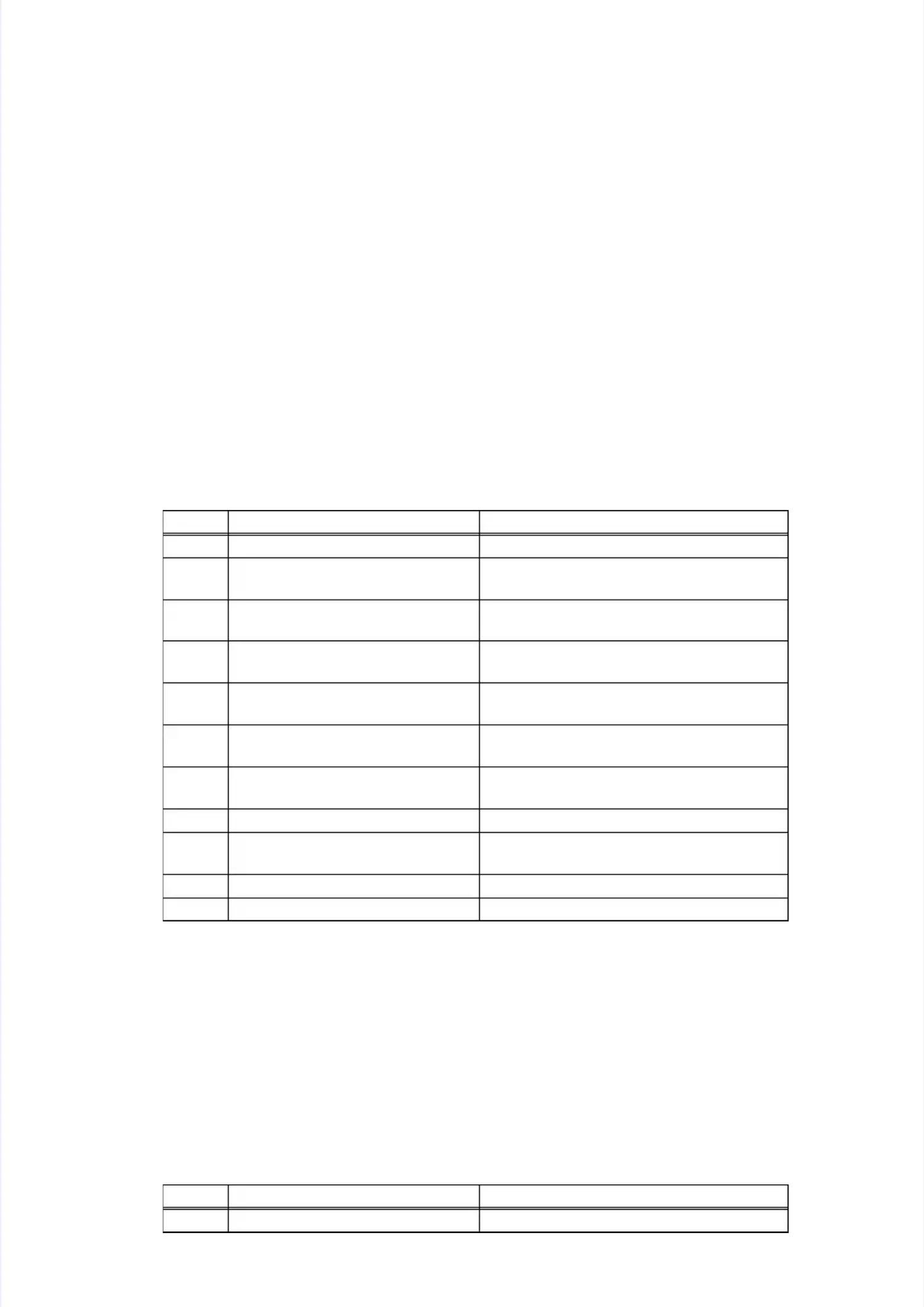

SStteepp CCaauussee RReemmeeddyy

11 FoForereigign on objbjecect it insnsidide te the he mamachchininee ReRemomove ve ththe fe fororeieign gn obobjejectct..

22

Gears around the plate up plateGears around the plate up plate

coming offcoming off

Reattach gears around the plate-up plate.Reattach gears around the plate-up plate.

33

Attachment failure of the motorAttachment failure of the motor

drive beltdrive belt

Reattach the motor drive belt.Reattach the motor drive belt.

44

Attachment failure of the laserAttachment failure of the laser

shutter armshutter arm

Reattach the laser shutter arm.Reattach the laser shutter arm.

55

Connection failure of the mainConnection failure of the main

motor harnessmotor harness

Reconnect the main motor harness.Reconnect the main motor harness.

66

Connection failure of the motorConnection failure of the motor

encoder PCB flat cableencoder PCB flat cable

Reconnect the motor encoder PCB flatReconnect the motor encoder PCB flat

cable.cable.

77

Connection failure of the pick-upConnection failure of the pick-up

solenoid harnesssolenoid harness

Reconnect the pick-up solenoid harness.Reconnect the pick-up solenoid harness.

88 MMoottoor r eennccooddeer r PPCCB B ffaaiilluurree RReeppllaacce e tthhe e mmoottoor r eennccooddeer r PPCCB B AASSSSYY..

99

Low voltage power supply PCBLow voltage power supply PCB

failurefailure

Replace the low voltage power supply PCBReplace the low voltage power supply PCB

unit.unit.

1100 LLaasseer r uunniit t ffaaiilluurree RReeppllaacce e tthhe e llaasseer r uunniitt..

1111 MMaaiin n PPCCB B ffaaiilluurree RReeppllaacce e tthhe e mmaaiin n PPCCB B AASSSSYY..

<User Check><User Check>

-- Check that the papCheck that the paper is set in the paper tray correctler is set in the paper tray correctlyy..

-- Flip over the paper in the papeFlip over the paper in the paper tray or rotate the paper 180 degrr tray or rotate the paper 180 degrees.ees.

-- Adjust the pAdjust the paper guide acaper guide accordincording to the paper sizeg to the paper size..

-- Check that the thicCheck that the thickness of the paper is withkness of the paper is within the standain the standard.rd.

-- Check tCheck that the phat the paper is naper is not damp.ot damp.

-- Check thCheck that there is nat there is no dust on the fo dust on the fuser uniuser unit.t.

-- Check wheCheck whether the papther the paper type is approper type is appropriate.riate.

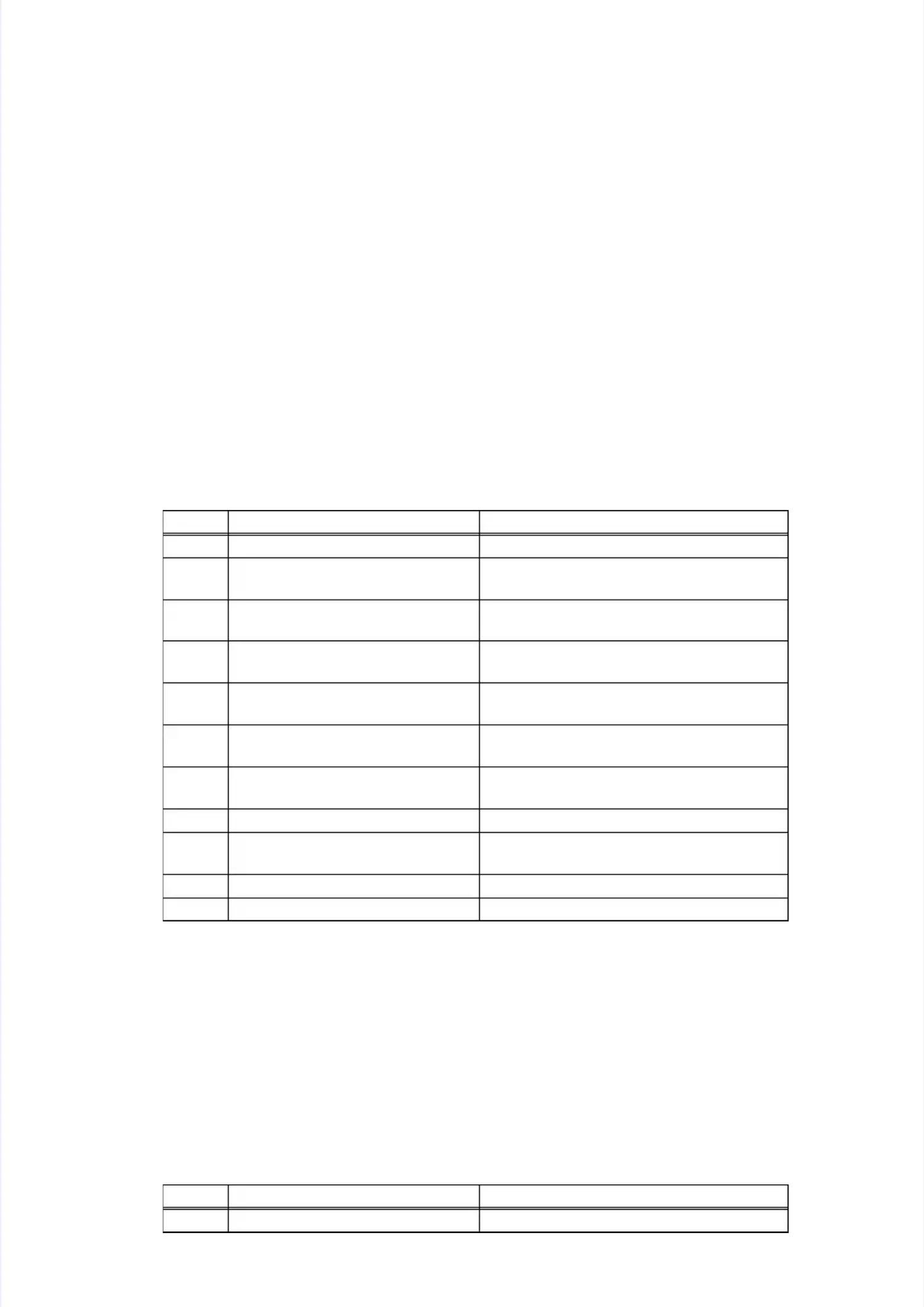

SStteepp CCaauussee RReemmeeddyy

11 FFuusseer r uunniit t ffaaiilluurree RReeppllaacce e tthhe e ffuusseer r uunniitt..

Loading...

Loading...