— 10 —

Maintenance Schedule / Checklist

ITEM TYPE OF MAINTENANCE FREQUENCY

Gearbox mounting bolts Model: 4200 - Torque to 160 ft - lbs

All other models: Torque to 275 ft - lbs

Daily or every 8 hours

Hydraulic motor mount bolts Torque to 75 ft - lbs. Daily or every 8 hours

Block - High Flow units only Torque to 420 in - lbs. Daily or every 8 hours

Shear Bolt Grade 2 Torque to 75 ft - lbs. Daily or every 8 hours

Blade Bolt/Nuts Torque to 775 ft - lbs. Daily or every 8 hours

Blade Inspection Check for damage, dullness or cracks. Blades

should rotate freely and be clear of obstructions.

Replace entire set of blades if damaged.

Daily or every use

Gearbox castle nut Torque to 450 ft - lbs. Daily or every 8 hours

Hoses and hose safety shield Check for wear, damage or leaks. Replace if dam-

aged.

Daily or every 8 hours

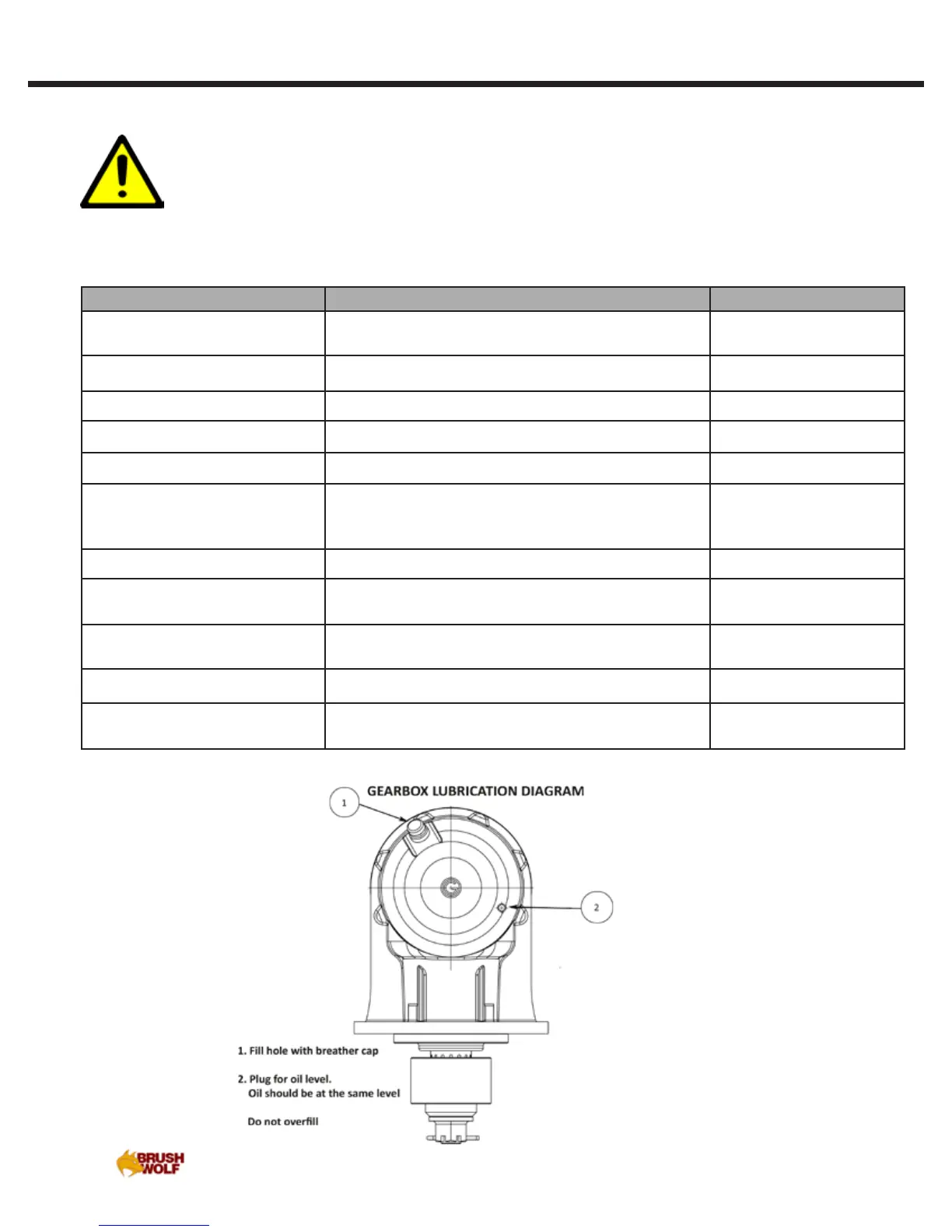

Gearbox lubricant Check oil - add 85 W 140 gear lube

DO NOT overfill - see diagram below

Once per week

Gearbox shaft Inspect shaft and remove foreign material. Inspect each use

Brush Wolf machine Clean the unit to view potential damage or ob-

structions that could result in poor performance.

As needed

CAUTION: Perform maintenance on a level surface with the unit

firmly on the ground and blocked. Shut off the hydraulic

power supply and disconnect hydraulic couplers.

Do Not loan your brush cutter to another skid steer owner.

The potential exists for hydraulic contamination and could

shorten the life of your skid steer or the hydraulic motor on

your Brush Wolf brush cutter.

Loading...

Loading...