If the furnace control CPU selects high-heat operation, the

inducer motor IDM remains running at high-speed, and the

high-heat pressure switch relay HPSR is de-energized to

close the NC contact. When sufficient pressure is available

the high-heat pressure switch HPS closes, and the high-heat

gas valve solenoid GV-HI is energized. The furnace control

CPU begins a 15-second prepurge period after the low-heat

pressure switch LPS closes. If the high-heat pressure switch

HPS fails to close and the low-heat pressure switch LPS

closes, the furnace will operate at low-heat gas flow rate

until the high-heat pressure switch closes for a maximum of

2 minutes after ignition.

2. Igniter Warm-Up-At end of the inducer prepurge period,

the Hot Surface Igniter HSI is energized for a 17-sec igniter

warm-up period.

3. Trial-For-Ignition Sequence-When the igniter warm-up

period is completed the main gas valve relay contacts GVR

close to energize the gas valve GV, the gas valve opens. The

gas valve GV permits gas flow to the burners where it is

ignited by the Hot Surface Igniter HSI. Five seconds after

the GVR closes, a 2-second flame period begins. The HSI

igniter will remain energized until the flame is sensed or

until the 2-second flame proving period begins.

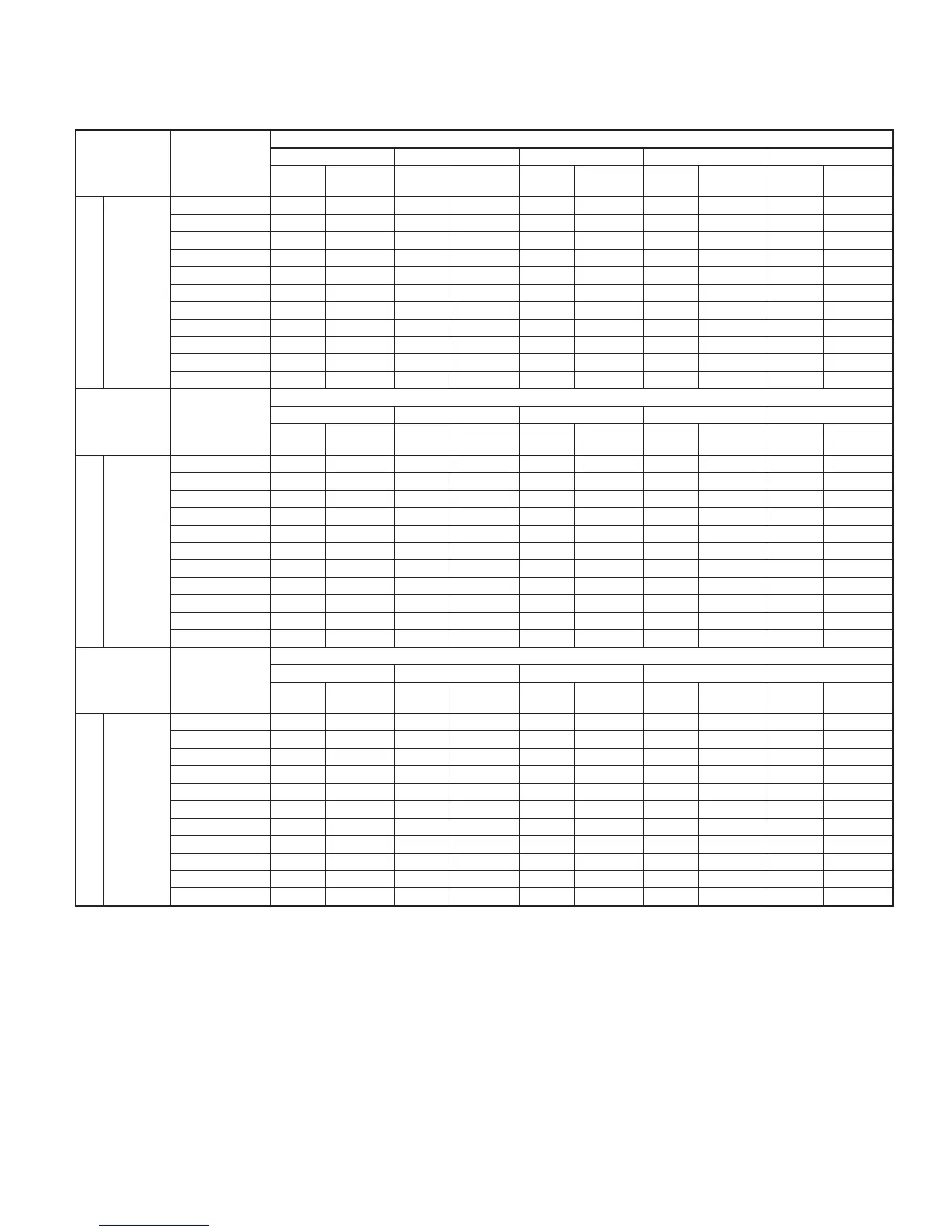

TABLE 10—MODEL 352MAV ORIFICE SIZE AND HIGH/LOW-HEAT MANIFOLD PRESSURE FOR CORRECT INPUT

FOR USE WITH 060 THROUGH 120 SIZE FURNACES ONLY

(TABULATED DATA BASED ON 20,000/13,000 BTUH PER BURNER, DERATED 2 PERCENT FOR EACH 1000 FT ABOVE SEA

LEVEL)*

ALTITUDE

RANGE

(FT)

AVG GAS

HEAT VALUE

(BTU/CU FT)

SPECIFIC GRAVITY OF NATURAL GAS

0.58 0.60 0.62 0.64 0.66

Orifice

no.

Manifold

Pressure

Orifice

no.

Manifold

Pressure

Orifice

no.

Manifold

Pressure

Orifice

no.

Manifold

Pressure

Orifice

no.

Manifold

Pressure

U.S.A. and Canada

0

to

2000

0%

derate

850 43 3.7/1.5 43 3.8/1.6 42 3.2/1.4 42 3.3/1.4 42 3.4/1.4

875 43 3.5/1.5 43 3.6/1.5 43 3.7/1.6 43 3.8/12.6 42 3.2/1.4

900 44 3.7/1.6 43 3.4/1.4 43 3.5/1.5 43 3.6/1.5 43 3.7/1.6

925 44 3.5/1.5 44 3.7/1.6 44 3.8/1.6 43 3.4/1.4 43 3.5/1.5

950 44 3.4/1.4 44 3.5/1.5 44 3.6/1.5 44 3.7/1.6 44 3.8/1.6

975 44 3.2/1.3 44 3.3/1.4 44 3.4/1.4 44 3.5/1.5 44 3.6/1.5

1000 45 3.7/1.6 45 3.8/1.6 44 3.2/1.4 44 3.4/1.4 44 3.5/1.5

1025 45 3.5/1.5 45 3.6/1.5 45 3.7/1.6 44 3.2/1.3 44 3.3/1.4

1050 45 3.3/1.4 45 3.4/1.5 45 3.6/1.5 45 3.7/1.6 45 3.8/1.6

1075 45 3.2/1.3 45 3.3/1.4 45 3.4/1.4 45 3.5/1.5 45 3.6/1.5

1100 47 3.6/1.5 47 3.7/1.6 45 3.2/1.4 45 3.4/1.4 45 3.5/1.5

ALTITUDE

RANGE

(FT)

AVG GAS

HEAT VALUE

(BTU/CU FT)

SPECIFIC GRAVITY OF NATURAL GAS

0.58 0.60 0.62 0.64 0.66

Orifice

no.

Manifold

Pressure

Orifice

no.

Manifold

Pressure

Orifice

no.

Manifold

Pressure

Orifice

no.

Manifold

Pressure

Orifice

no.

Manifold

Pressure

U.S.A. and Canada

Altitudes

2001

to

3000

or

Canada

Altitudes

2000

to

4500

5%

derate

775 43 3.8/1.6 42 3.2/1.4 42 3.3/1.4 42 3.4/1.4 42 3.5/1.5

800 43 3.5/1.5 43 3.7/1.5 43 3.8/1.6 42 3.2/1.4 42 3.3/1.4

825 44 3.8/1.6 43 3.4/1.5 43 3.6/1.5 43 3.7/1.5 43 3.8/1.6

850 44 3.6/1.5 44 3.7/1.6 44 3.8/1.6 43 3.5/1.5 43 3.6/1.5

875 44 3.4/1.4 44 3.5/1.5 44 3.6/1.5 44 3.7/1.6 43 3.4/1.4

900 44 3.2/1.4 44 3.3/1.4 44 3.4/1.4 44 3.5/1.5 44 3.6/1.5

925 45 3.7/1.5 45 3.8/1.6 44 3.2/1.4 44 3.3/1.4 44 3.4/1.5

950 45 3.5/1.5 45 3.6/1.5 45 3.7/1.6 45 3.8/1.6 44 3.3/1.4

975 45 3.3/1.4 45 3.4/1.4 45 3.5/1.5 45 3.6/1.5 45 3.8/1.6

1000 47 3.7/1.6 45 3.2/1.4 45 3.4/1.4 45 3.5/1.5 45 3.6/1.5

1025 47 3.6/1.5 47 3.7/1.6 45 3.2/1.3 45 3.3/1.4 45 3.4/1.4

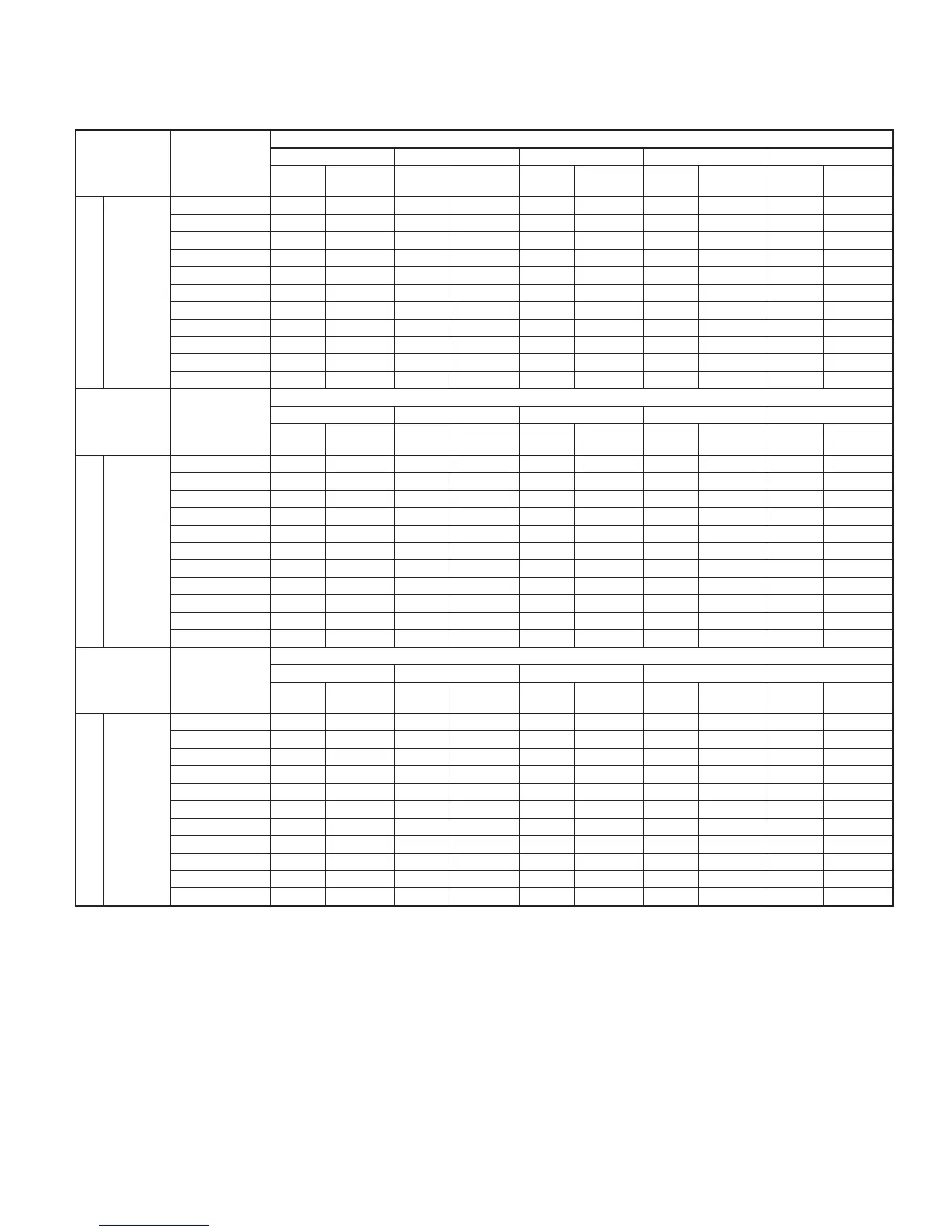

ALTITUDE

RANGE

(FT)

AVG GAS

HEAT VALUE

(BTU/CU FT)

SPECIFIC GRAVITY OF NATURAL GAS

0.58 0.60 0.62 0.64 0.66

Orifice

no.

Manifold

Pressure

Orifice

no.

Manifold

Pressure

Orifice

no.

Manifold

Pressure

Orifice

no.

Manifold

Pressure

Orifice

no.

Manifold

Pressure

U.S.A. Only

3001

to

4000

7%

derate

750 43 3.7/1.6 43 3.8/1.6 42 3.3/1.4 42 3.4/1.4 42 3.5/1.5

775 43 3.5/1.5 43 3.6/1.5 43 3.7/1.6 43 3.8/1.6 42 3.2/1.4

800 44 3.7/1.6 43 3.4/1.4 43 3.5/1.5 43 3.6/1.5 43 3.7/1.6

825 44 3.5/1.5 44 3.6/1.5 44 3.8/1.6 43 3.4/1.4 43 3.5/1.5

850 44 3.3/1.4 44 3.4/1.4 44 3.5/1.5 44 3.7/1.5 44 3.8/1.6

875 45 3.8/1.6 44 3.2/1.4 44 3.3/1.4 44 3.5/1.5 44 3.6/1.5

900 45 3.6/1.5 45 3.7/1.6 45 3.8/1.6 44 3.3/1.4 44 3.4/1.4

925 45 3.4/1.4 45 3.5/1.5 45 3.6/1.5 45 3.7/1.6 44 3.2/1.3

950 45 3.2/1.4 45 3.3/1.4 45 3.4/1.5 45 3.5/1.5 45 3.7/1.5

975 47 3.6/1.5 45 3.2/1.3 45 3.3/1.4 45 3.4/1.4 45 3.5/1.5

1000 47 3.5/1.5 47 3.6/1.5 45 3.7/1.6 45 3.2/1.4 45 3.3/1.4

* Orifice numbers shown in shading are factory installed.

NOTE: Percents of derate are based on midpoints of U.S. altitude ranges.

—41—

Loading...

Loading...