7. Check dry fit of pipe and mark insertion depth on pipe.

NOTE: It is recommended that all pipes be cut, prepared, and

preassembled before permanently cementing any joint.

8. After pipes have been cut and preassembled, apply gener-

ous layer of cement primer to pipe fitting socket and end of

pipe to insertion mark. Quickly apply approved cement to

end of pipe and fitting socket (over primer). Apply cement

in a light, uniform coat on inside of socket to prevent

buildup of excess cement. Apply second coat.

9. While cement is still wet, twist pipe into socket with 1/4

turn. Be sure pipe is fully inserted into fitting socket.

10. Wipe excess cement from joint. A continuous bead of

cement will be visible around perimeter of a properly made

joint.

11. Handle pipe joints carefully until cement sets.

12. Support combustion-air and vent piping a minimum of

every 5 ft (3 ft for SDR-21 or -26 PVC) using perforated

metal hanging strap.

13. Slope combustion-air and vent pipes downward toward

furnace a minimum of 1/4-in. per linear ft with no sags

between hangers.

14. Use appropriate methods to seal openings where vent and

combustion-air pipes pass through roof or side wall.

D. Concentric Vent and Combustion-Air

TerminationKit Installation

NOTE: If these instructions differ from those packaged with

termination kit, follow kit instructions.

Combustion-air and vent pipes must terminate outside structure. A

factory accessory termination kit must be installed in 1 of the

installations shown in Fig. 37, 38, 39, 40, and 41. Four termination

kits are available.

See Table 6 for additional termination information.

1. The 2-in. termination bracket kit is for 1-in., 1-1/2 in., and

2-in. diameter 2-pipe termination systems.

2. The 3-in. termination bracket kit is for 2-1/2 in., 3-in., and

4-in. diameter 2-pipe termination systems.

3. The 2-in. concentric vent/air termination kit is for 1-in.,

1-1/2 in., 2-in., and 2-1/2 in. diameter pipe systems when

single penetration of wall or roof is desired.

4. The 3-in. concentric vent/air termination kit is for 2-1/2 in.,

3-in., and 4-in. diameter pipe systems when single penetra-

tion of wall or roof is desired.

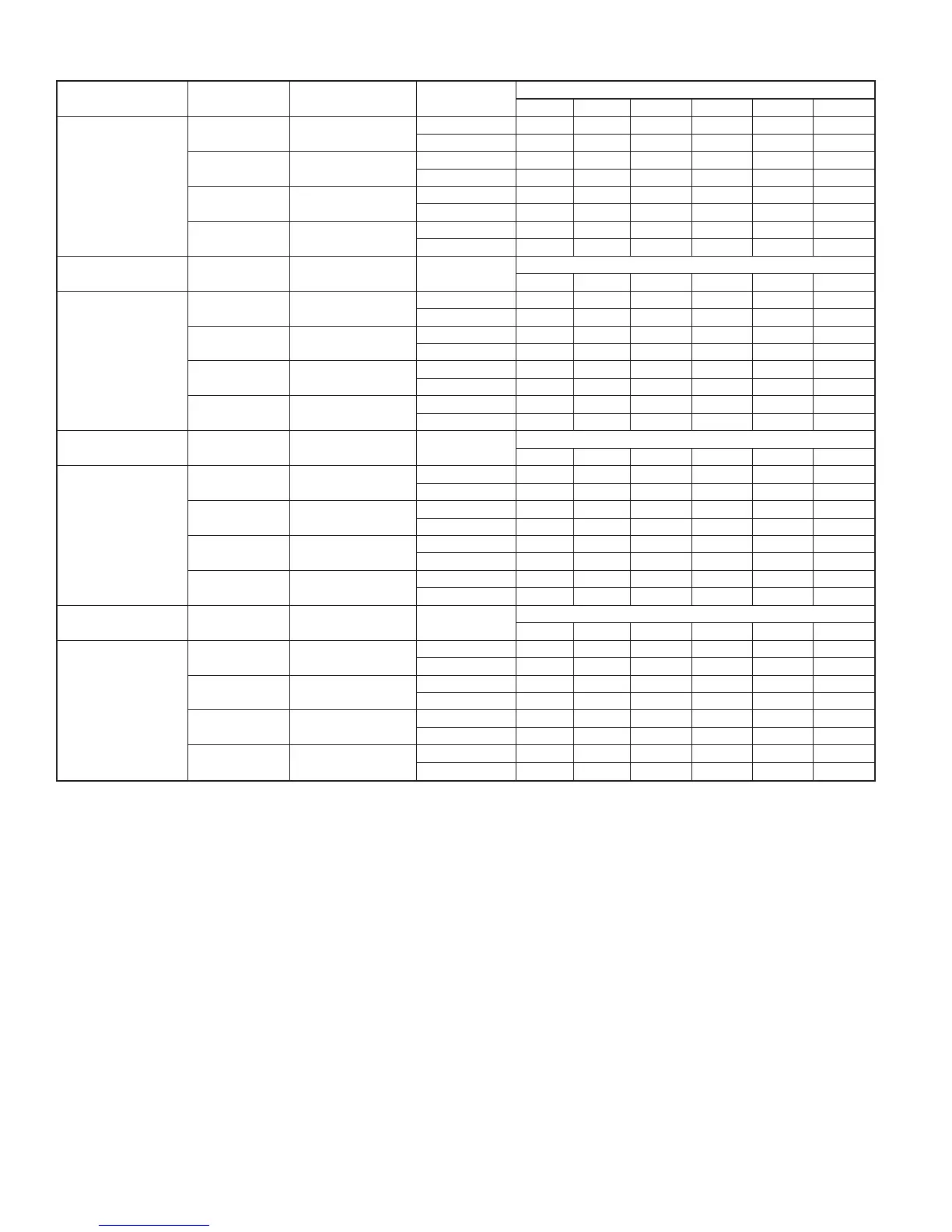

TABLE 7-MAXIMUM ALLOWABLE PIPE LENGTH (FT) (CONTINUED)

ALTITUDE (FT) UNIT SIZE

TERMINATION

TYPE

PIPE DIA

(IN.)*

NUMBER OF 90° ELBOWS

123456

4001 to 5000‡

036060

2 Pipe or 2-in

Concentric

1-1/2 15 10 5 NA NA NA

2 645958535252

036080

048080

2 Pipe or 2-in

Concentric

2 443926212011

2-1/2 70 70 70 70 70 70

048100

060100

2 Pipe or 3-in

Concentric

2-1/2 31 22 13 12 NA NA

3 707067625752

060120

2 Pipe or 3-in.

Concentric

3† no disk 53 46 40 33 26 20

4† no disk 70 70 70 70 70 70

ALTITUDE (FT) UNIT SIZE

TERMINATION

TYPE

PIPE DIA

(IN.)*

NUMBER OF 90° ELBOWS

123456

5001 to 6000‡

036060

2 Pipe or 2-in

Concentric

1-1/2 14 9 NA NA NA NA

2 605554494847

036080

048080

2 Pipe or 2-in

Concentric

2 4136231817 8

2-1/2 70 70 70 70 70 70

048100

060100

2 Pipe or 3-in

Concentric

2-1/2 29 21 12 11 NA NA

3 706762575247

060120

2 Pipe or 3-in.

Concentric

3† no disk 42 35 29 22 15 9

4† no disk 70 70 70 70 70 70

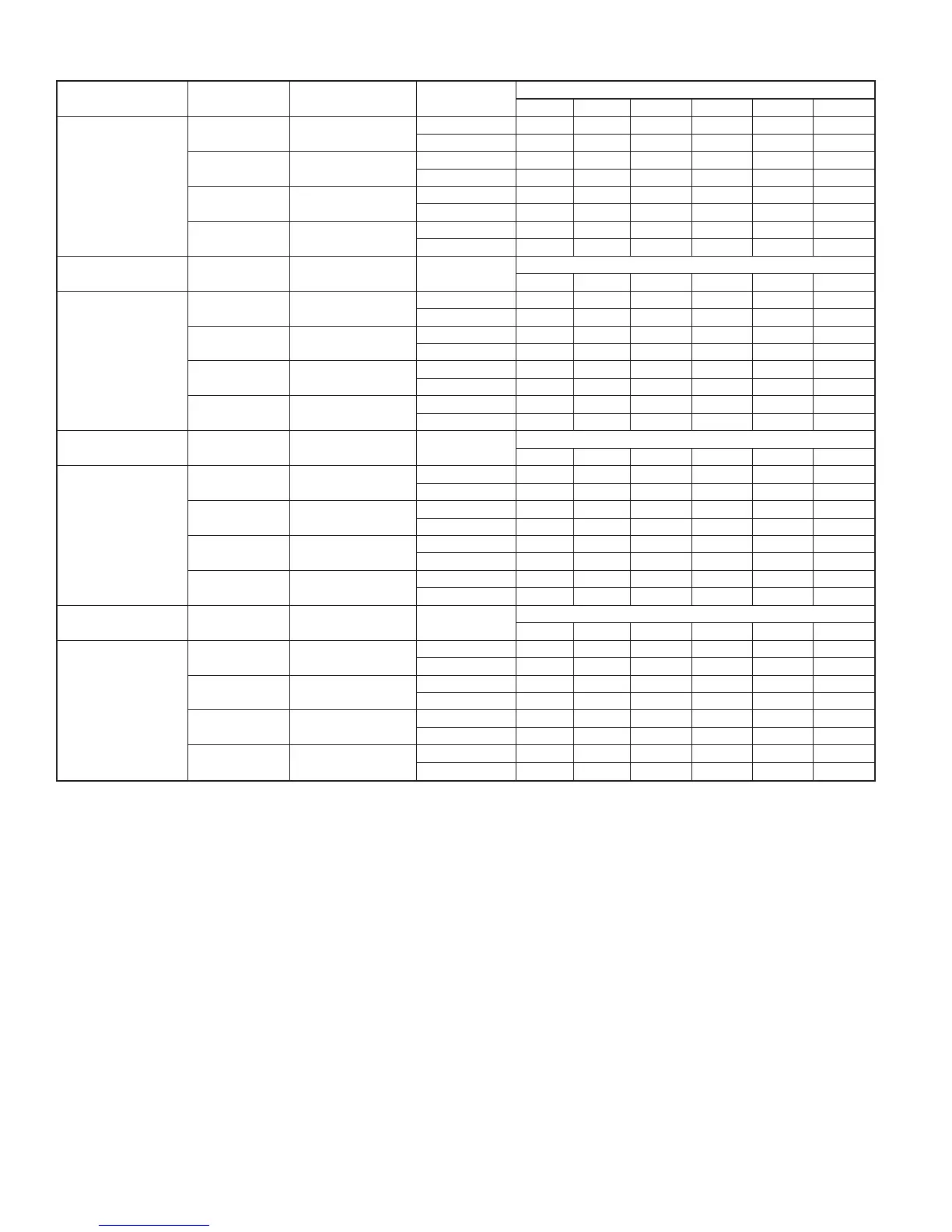

ALTITUDE (FT) UNIT SIZE

TERMINATION

TYPE

PIPE DIA

(IN.)*

NUMBER OF 90° ELBOWS

123456

6001 to 7000‡

036060

2 Pipe or 2-in

Concentric

1-1/2 13 8 NA NA NA NA

2 575250454443

036080

048080

2 Pipe or 2-in

Concentric

2 3833211615 6

2-1/2 70 70 68 67 66 64

048100

060100

2 Pipe or 3-in

Concentric

2-1/2 27 19 10 9 NA NA

3 686358534843

060120

2 Pipe or 3-in.

Concentric

3† no disk 31 24 18 11 NA NA

4† no disk 70 70 70 70 67 62

ALTITUDE (FT) UNIT SIZE

TERMINATION

TYPE

PIPE DIA

(IN.)*

NUMBER OF 90° ELBOWS

123456

7001 to 8000‡

036060

2 Pipe or 2-in

Concentric

1-1/2 12 7 NA NA NA NA

2 534846414038

036080

048080

2 Pipe or 2-in

Concentric

2 3631191412NA

2-1/2 66 65 63 62 60 59

048100

060100

2 Pipe or 3-in

Concentric

2-1/2 25 17 8 7 NA NA

3 635853484338

060120

2 Pipe or 3-in.

Concentric

3† no disk 20 13 7 NA NA NA

4† no disk 61 56 51 46 41 36

See notes at end of table.

—30—

Loading...

Loading...