2. Attach vent pipe to furnace as follows:

a. Determine location of vent pipe connection to inducer

housing as shown in Fig. 34 for application.

b. Reposition elastomeric (rubber) inducer housing outlet

cap and clamp to appropriate unused inducer housing

connection. Tighten clamp.

CAUTION: UNIT DAMAGE HAZARD

Failure to follow this caution may result in unit compo-

nent damage.

Inducer housing outlet cap must be installed and fully

seated against inducer housing. Clamp must be tightened

to prevent any condensate leakage.

c. Install pipe support (factory-supplied in loose parts bag)

into selected furnace casing vent pipe hole. Pipe support

should be positioned at bottom of casing hole.

CAUTION: UNIT DAMAGE HAZARD

Failure to follow this caution may result in unit compo-

nent damage.

Vent pipe must be installed and fully seated against

inducer housing internal stop. Clamp must be tightened to

prevent any condensate leakage.

NOTE: A 2-in. diameter pipe must be used within the furnace

casing. Make all pipe diameter transitions outside furnace casing.

d. Be certain that mating surfaces of inducer housing

connection, elastomeric coupling, and 2-in. diameter

vent pipe are clean and dry. Assemble the elastomeric

(rubber) vent coupling (with 2 loose clamps) onto

inducer housing connection. Insert the 2-in. diameter

vent pipe through the elastomeric (rubber) coupling and

fully into inducer housing connection until it bottoms on

the internal stop. Tighten both clamps to secure the pipe

to inducer housing. Tighten the clamp screws to 15

in.-lb. of torque.

e. Install casing hole filler plug (factory-supplied in loose

parts bag) in unused combustion-air pipe casing hole.

Vent Extension Pipe: Furnaces with 100,000 Btuh and larger

inputs are supplied with a PVC vent extension pipe (2-in. diameter

by 12-in. long). This pipe has a built-in channel to assist vent

condensate disposal. When this vent extension pipe is supplied, it

must be used to connect the field vent pipe to furnace inducer

housing on ALL upflow and downflow applications.

NOTE: See label on vent extension pipe for proper installation.

This pipe may be shortened if an elbow is used to connect vent

extension tube to field installed vent pipe.

3. Working from furnace to outside, cut pipe to required

length(s).

4. Deburr inside and outside of pipe.

5. Chamfer outside edge of pipe for better distribution of

primer and cement.

6. Clean and dry all surfaces to be joined.

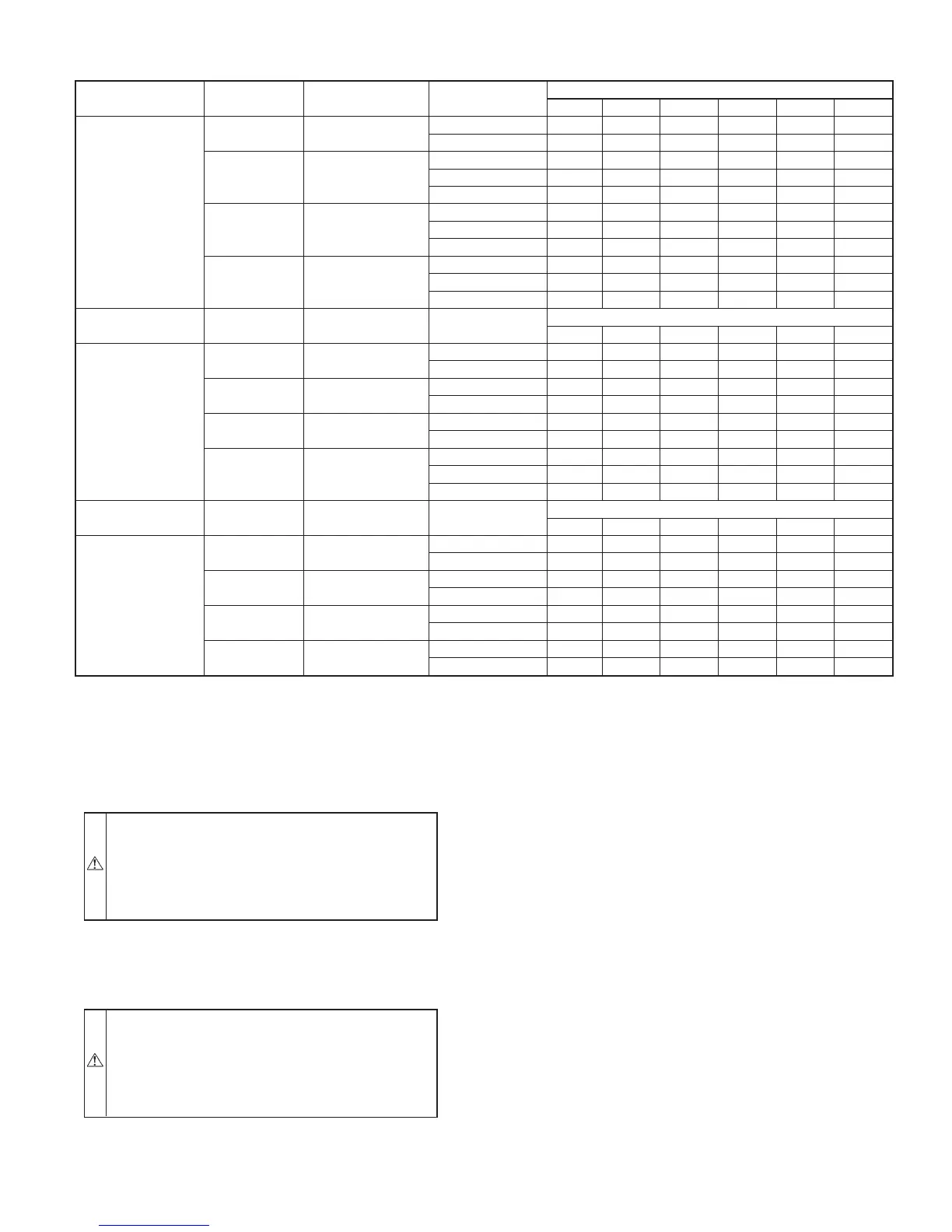

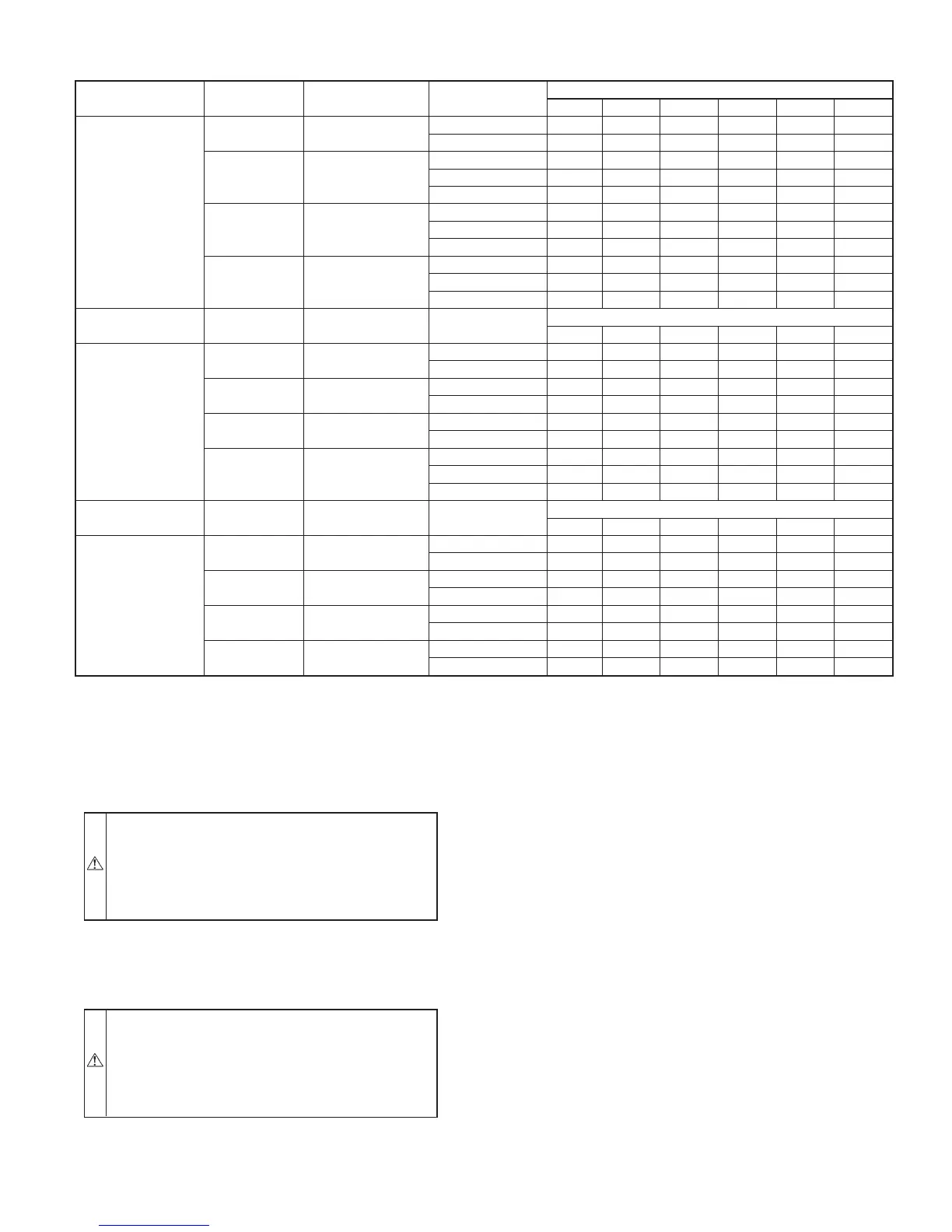

TABLE 7—MAXIMUM ALLOWABLE PIPE LENGTH (FT)

ALTITUDE (FT) UNIT SIZE

TERMINATION

TYPE

PIPE DIA

(IN.)*

NUMBER OF 90° ELBOWS

123456

0 to 2000

036060

2 Pipe or 2-in

Concentric

1-1/2 20 15 10 5 NA NA

2 707070707070

036080

048080

2 Pipe or 2-in

Concentric

1-1/2 10 NA NA NA NA NA

2 555035303020

2-1/2 70 70 70 70 70 70

048100

060100

2 Pipe or 3-in

Concentric

2 5 NA NA NA NA NA

2-1/2 40 30 20 20 10 NA

3 707070707070

060120

2 Pipe or 3-in.

Concentric

2-1/2 one disk 10 NA NA NA NA NA

3† 45 40 35 30 25 20

3† no disk 70 70 70 70 70 70

ALTITUDE (FT) UNIT SIZE

TERMINATION

TYPE

PIPE DIA

(IN.)*

NUMBER OF 90° ELBOWS

123456

2001 to 3000

036060

2 Pipe or 2-in

Concentric

1–1/2 17 12 7 NA NA NA

2 706766616161

036080

048080

2 Pipe or 2-in

Concentric

2 494430252515

2-1/2 70 70 70 70 70 70

048100

060100

2 Pipe or 3-in

Concentric

2-1/2 35 26 16 16 6 NA

3 707070706661

060120

2 Pipe or 3-in.

Concentric

3 14 9 NA NA NA NA

3† no disk 70 70 63 56 50 43

4† no disk 70 70 70 70 70 70

ALTITUDE (FT) UNIT SIZE

TERMINATION

TYPE

PIPE DIA

(IN.)*

NUMBER OF 90° ELBOWS

123456

3001 to 4000

036060

2 Pipe or 2-in

Concentric

1-1/2 16 11 6 NA NA NA

2 686362575756

036080

048080

2 Pipe or 2-in

Concentric

2 464128232213

2-1/2 70 70 70 70 70 70

048100

060100

2 Pipe or 3-in

Concentric

2-1/2 33 24 15 14 5 NA

3 707070666156

060120

2 Pipe or 3-in.

Concentric

3† no disk 65 58 51 44 38 31

4† no disk 70 70 70 70 70 70

See notes at end of table.

—29—

Loading...

Loading...