INSTALLATION

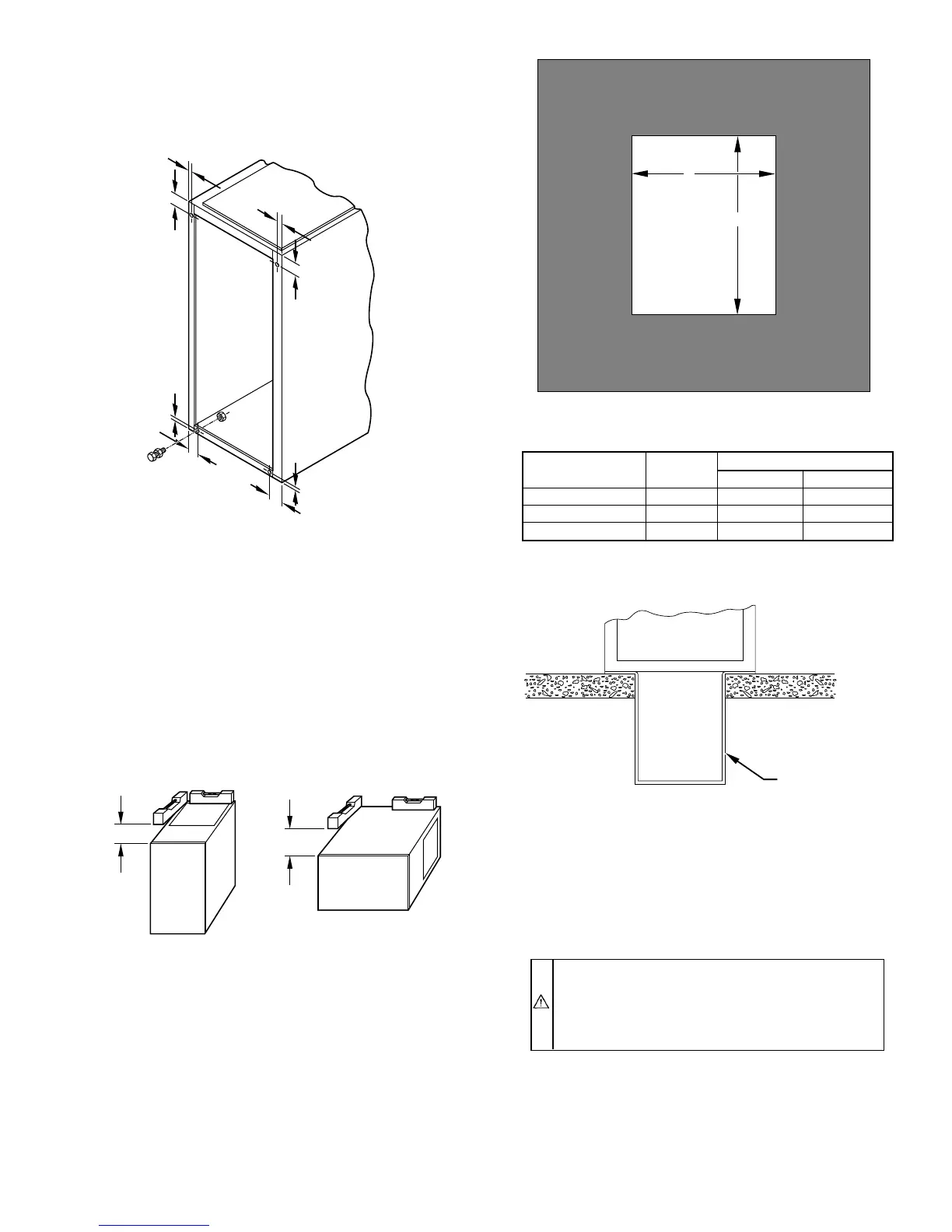

I. LEVELING LEGS (IF DESIRED)

When furnace is used in upflow position with side inlet(s), leveling

legs may be desired. (See Fig. 12.) Install field-supplied,

corrosion-resistant 5/16-in. machine bolts and nuts.

NOTE: The maximum length of bolt should not exceed 1-1/2 in.

1. Position furnace on its back. Locate and drill a 5/16-in.

diameter hole in each bottom corner of furnace. (See Fig.

12.) Holes in bottom closure panel may be used as guide

locations.

2. For each hole, install nut on bolt and then install bolt and

nut in hole. (Install flat washer if desired.)

3. Install another nut on other side of furnace base. (Install flat

washer if desired.)

4. Adjust outside nut to provide desired height, and tighten

inside nut to secure arrangement.

NOTE: Bottom closure must be used when leveling legs are used.

See Bottom Closure Panel section.

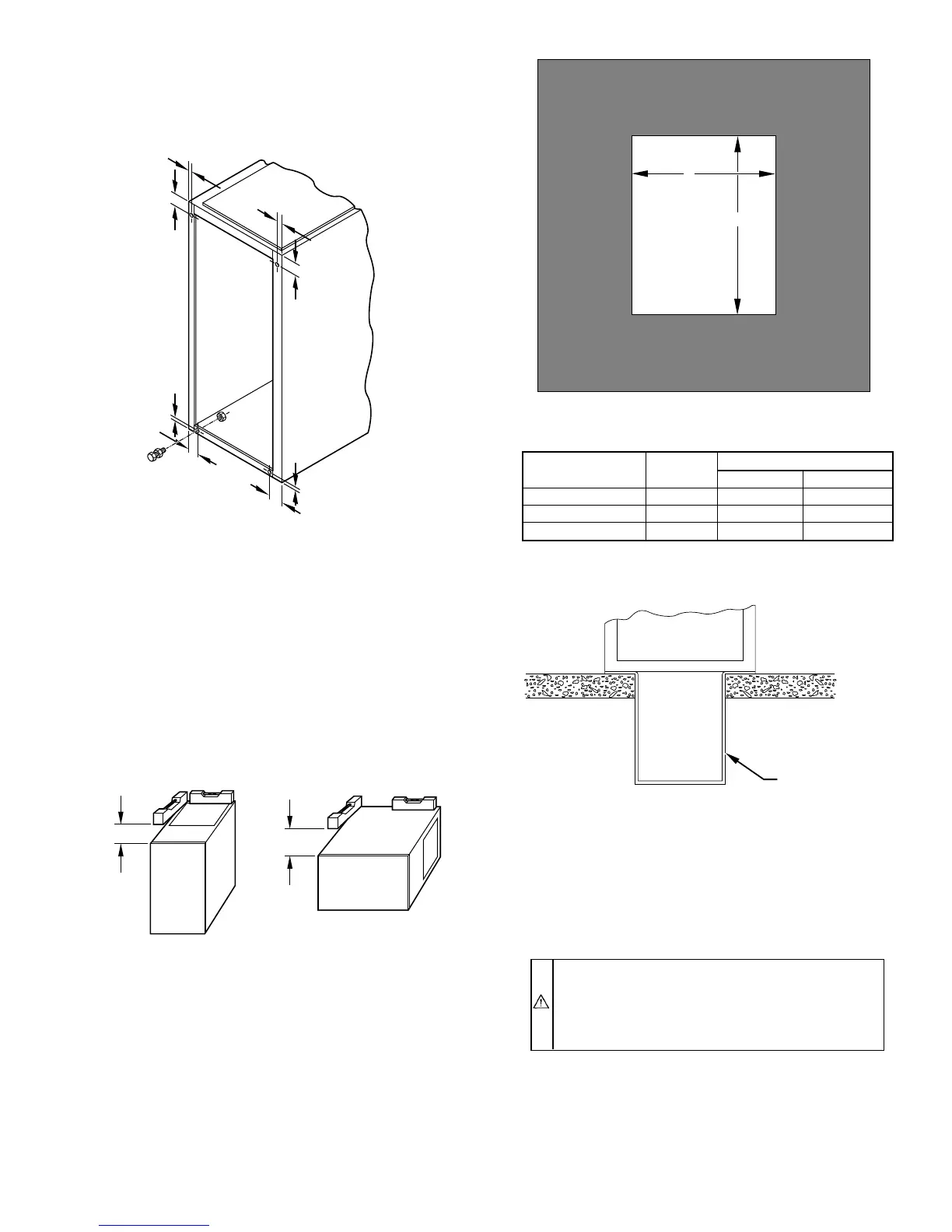

II. INSTALLATION ON A CONCRETE SLAB

1. Construct hole in floor per dimensions in Fig. 13.

2. Place plenum and furnace as shown in Fig. 14.

III. INSTALLATION ON A COMBUSTIBLE FLOOR

(DOWNFLOW APPLICATIONS)

1. Cut and frame hole in floor per dimensions in Installation

Instructions packaged with downflow subbase kit.

NOTE: Remove furnace perforated, discharge duct flanges when

they interfere with mating flanges on coil on downflow subbase.

To remove furnace perforated, discharge duct flange, use wide

duct pliers or duct flange tool to bend flange back and forth until

it breaks off. Be careful of sharp edges. (See Fig. 15.)

WARNING: Do not bend duct flanges inward as shown

in Fig. 15. This will affect airflow across heat exchangers

and may cause limited cycling or premature heat ex-

changer failure. Remove duct flange completely or bend

it inward a minimum of 210° as shown in Fig. 15.

2. When complete, downflow subbase, plenum, and furnace

(or coil casing when used) should be installed as shown in

Fig. 16.

Fig. 12—Leveling Legs

A89014

1

3

⁄4″

1

3

⁄4″

1

3

⁄4″

1

3

⁄4″

5

⁄16″

5

⁄16″

5

⁄16″

5

⁄16″

NOTE: For proper furnace operation, install furnace so that it is

level or pitched forward within 1/2 in. to ensure proper condensate

drainage from secondary heat exchangers.

A93025

UPFLOW OR DOWNFLOW HORIZONTAL

FRONT

LEVEL (0″)

TO

1

⁄2″ MAX

LEVEL (0″)

TO

1

⁄2″ MAX

FRONT

Fig. 13—Floor Opening in Concrete Slab

OPENING DIMENSIONS (IN.)

FURNACE

CASING WIDTH

A

B

Heat Only Heat/Cool*

17-1/2 16-7/16 19-5/8 19-7/16

21 19-7/8 19-5/8 19-7/16

24-1/2 23-7/16 19-5/8 19-7/16

* These dimensions apply when a model CB or CD Evaporator Coil casing is

to be installed.

A73382

HOLE IN

FLOOR

A

B

Fig. 14—Furnace on a Concrete Slab

(Non-Garage Installation)

A73383

—13—

Loading...

Loading...