3. Insofar as is practical, close all building doors and windows

and all doors between space in which appliances remaining

connected to common vent system are located and other

spaces of building. Turn on clothes dryers and any appli-

ance not connected to common vent system. Turn on any

exhaust fans, such as range hoods and bathroom exhausts,

so they operate at maximum speed. Do not operate a

summer exhaust fan. Close fireplace dampers.

4. Follow lighting instructions and place appliance in opera-

tion. Adjust thermostat so appliance operates continuously.

5. Test for flue gas spillage at drafthood relief opening after 5

minutes of main burner operation. Use flame of a match or

candle, etc.

6. After it has been determined that each appliance remaining

connected to common vent system properly vents when

tested as above, return doors, windows, exhaust fans,

fireplace dampers, any other gas burning appliances to their

previous condition of use.

7. If improper venting is observed during any of above tests,

common vent system must be corrected. Vent system or

vent connectors may need to be resized. For any other

appliances when resizing vent systems or vent connectors,

system or connector must be sized to approach minimum

size as determined using appropriate table found in Part 11

of NFGC or Section 5 of NSCNGPIC.

II. COMBUSTION-AIR AND VENT PIPING

A. General

Combustion-air and vent pipe fittings must conform to American

National Standards Institute (ANSI) standards and American

Society for Testing and Materials (ASTM) standards D1785

(schedule-40 PVC), D2665 (PVC-DWV), D2241 (SDR-21 and

SDR-26 PVC), D2661 (ABS-DWV), F628 (schedule-40 ABS), or

F891 (PVC-DWV cellular core). Pipe cement and primer must

conform to ASTM standards D2564 (PVC) or D2235 (ABS). See

Table 5 for maximum pipe lengths and Fig. 31, 32, 33, 34, and 35

for exterior piping arrangements.

In Canada construct all combustion-air and vent pipes for this unit

of CSA or ULC certified schedule-40 PVC, PVC-DWV or

ABS-DWV pipe and pipe cement. SDR pipe is NOT approved in

Canada.

NOTE: Furnace combustion-air and vent pipe connections are

sized for 2-in. pipe. Any pipe size change should be made outside

furnace casing in vertical pipe. (See Fig. 27.) This allows proper

drainage of vent condensate.

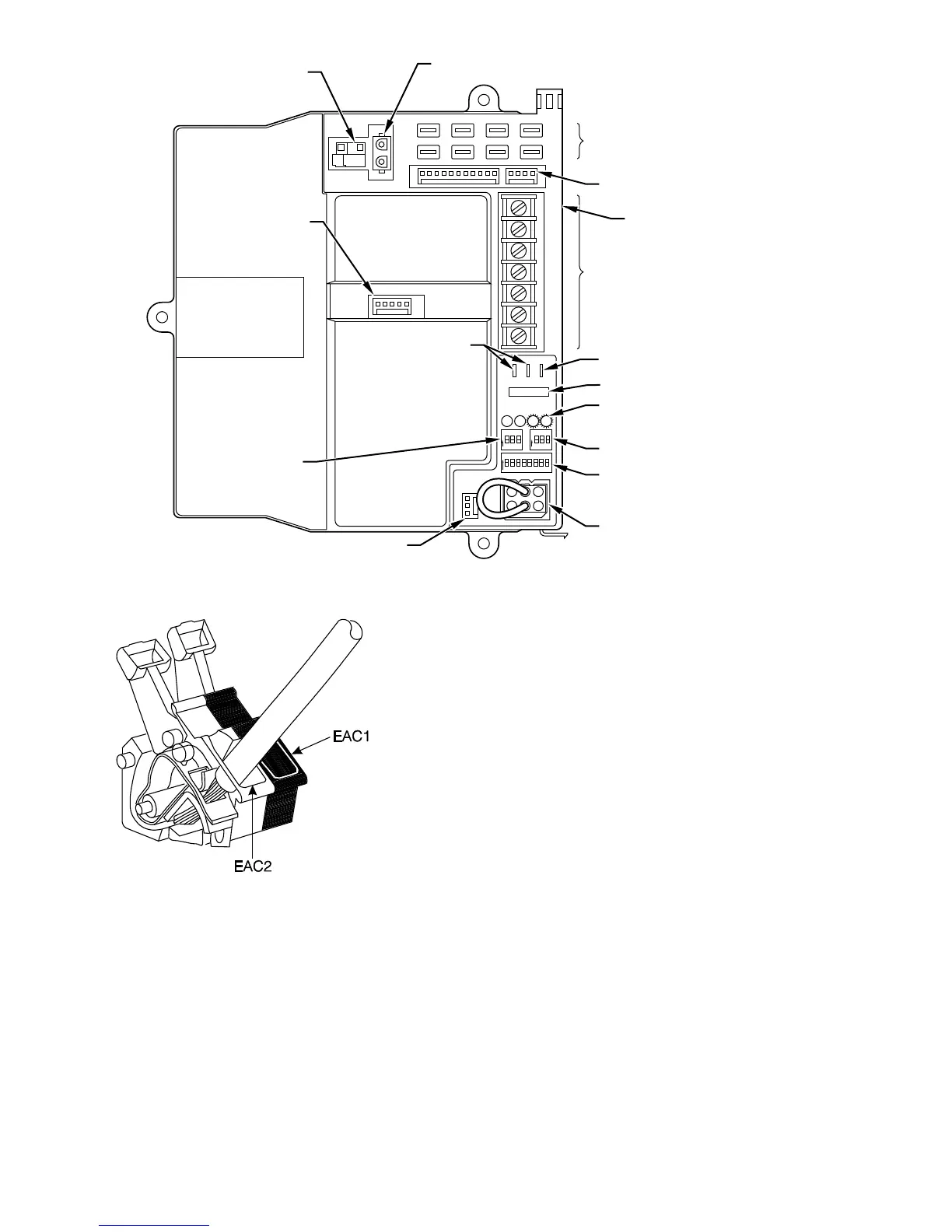

Fig. 25—Control Center

A93062

W2

COM

24V

W/W1 Y/Y2

RG

HUM

HOT SURFACE

IGNITOR CONNECTOR

EAC-ELECTRONIC AIR

CLEANER TERMINALS

(115-VAC 1 AMP MAX)

115-V

CONNECTORS

24-V THERMOSTAT

TERMINALS

PRESSURE SWITCH

CONNECTOR

HUM-HUMIDIFIER

TERMINAL

(24-VAC 0.5 AMP MAX)

TRANSFORMER

24-V CONNECTORS

3-AMP FUSE

STATUS AND DIAGNOSTIC

LED LIGHTS

AIR CONDITIONING

(A/C) SETUP SWITCH

SETUP SWITCHES

(SW) AND BLOWER

OFF DELAY SETUP

SWITCHES

MODEL PLUG

COMMUNICATION

CONNECTOR

CONTINUOUS

FAN (CF) SETUP

SWITCHES

MAIN BLOWER

CONTROL WIRE

CONNECTOR

DEHUMIDIFIER (DH)

CONNECTOR

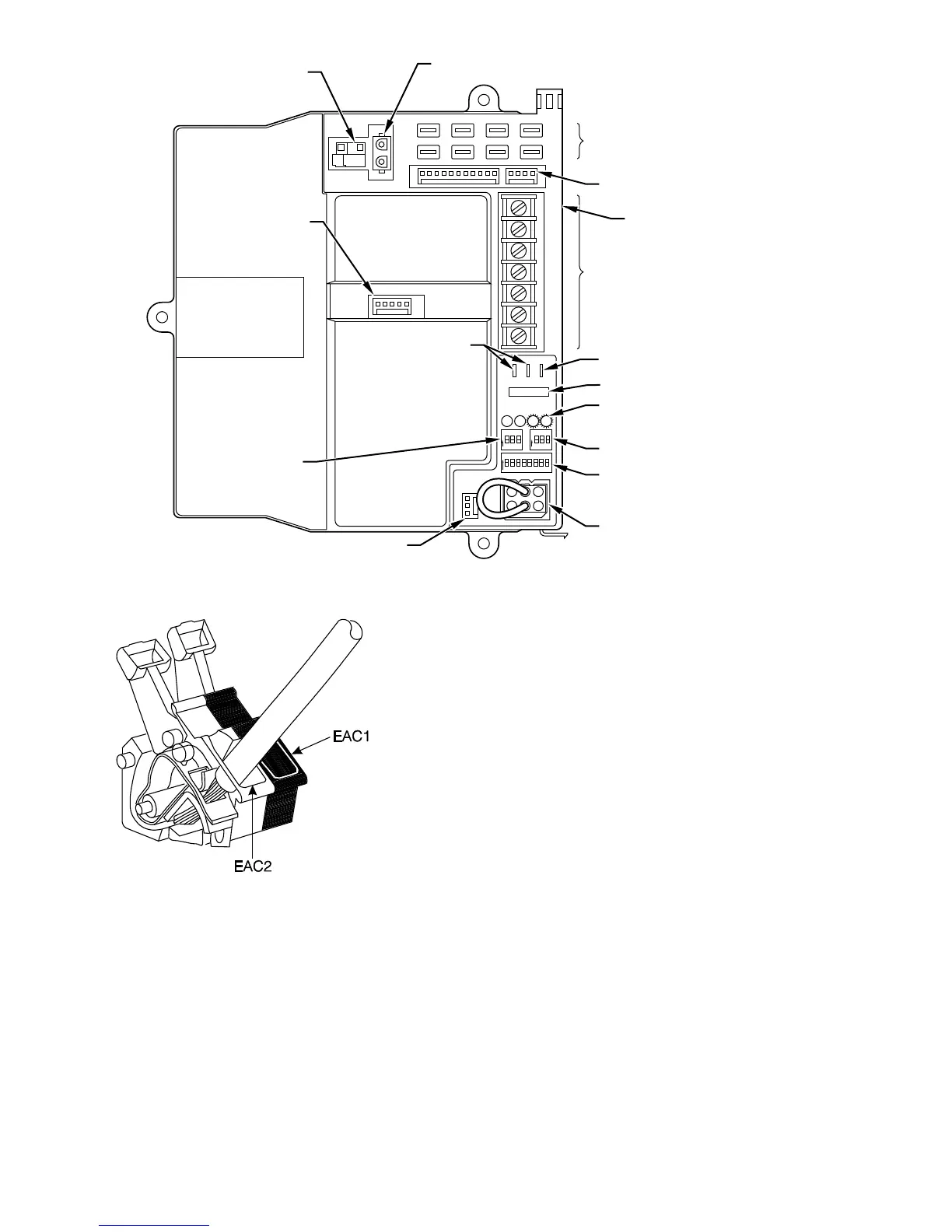

Fig. 26—EAC Terminals on Control Center

A93053

—20—

Loading...

Loading...