19

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

C10999

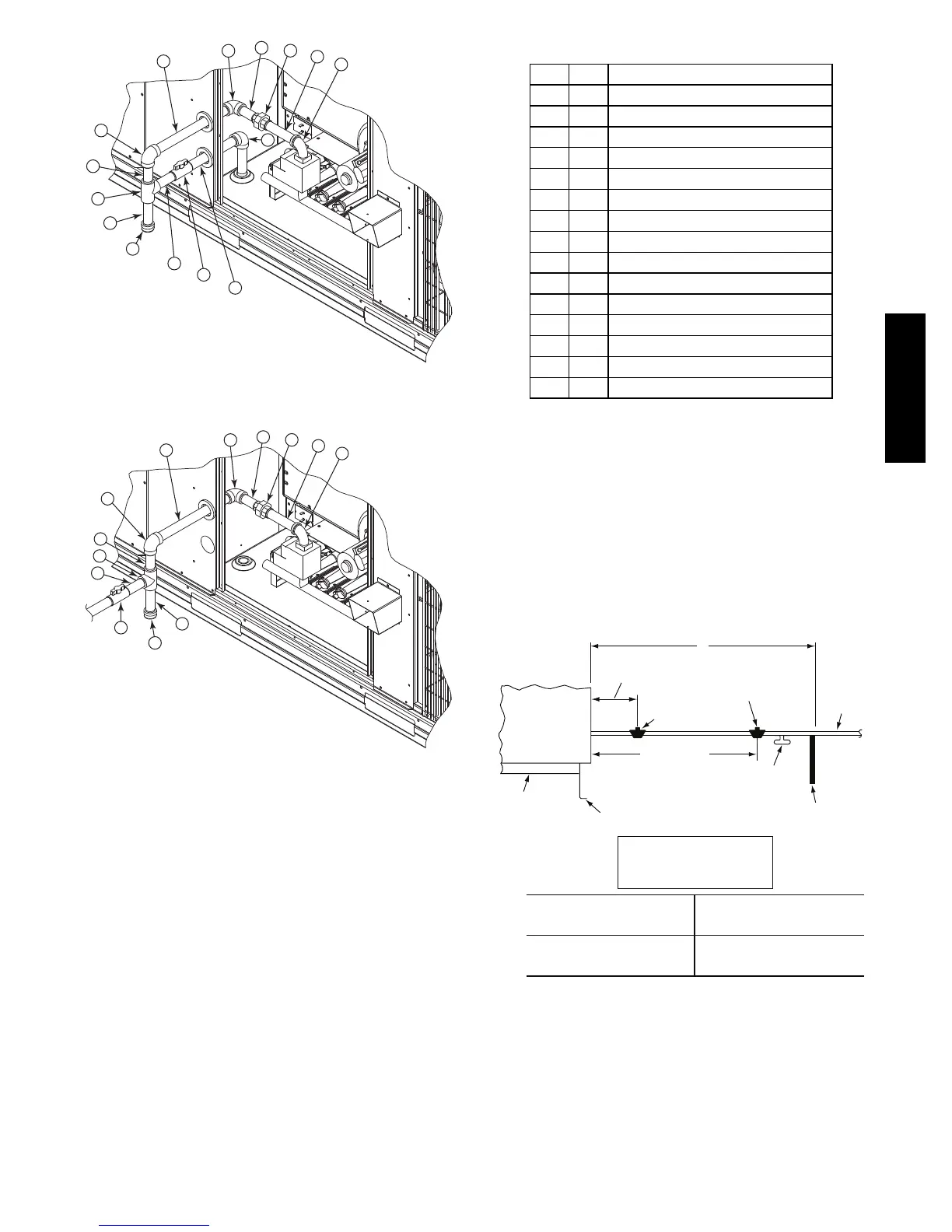

Fig. 17 -- Gas Supply Line Piping with Thru--Base

13

12

11

10

9

8

7

6

5

4

3

2

1

C101006

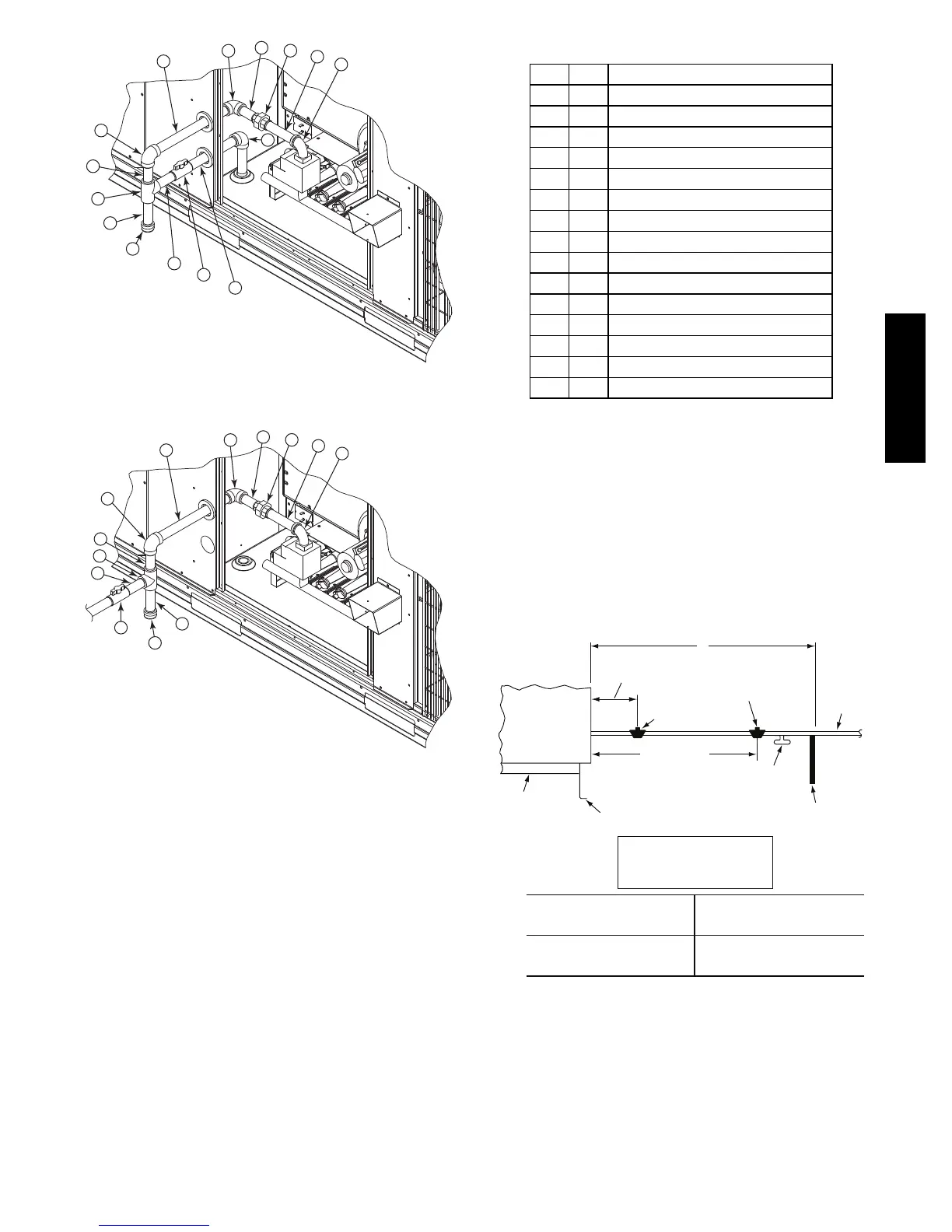

Fig. 18 -- Gas Supply Line Piping

Table 4 – Typical

3

/

4

--in NPT Field Supplied Piping Parts

Item Qty Description

1 1 90 Deg Street Elbow

2 1 5 Inch Long Nipple

3 1 Ground---Joint Union

4 1 3 Inch Long Nipple

5 1 90 Deg Elbow

6 1 12 Inch Long Nipple

7 1 90 Deg Elbow

8 1 3 Inch Long Nipple

9 1 TEE

10 1 4 Inch Long Nipple (Sediment Trap)

11 1 Cap

12 1 3

1

/

2

Inch Long Nipple

13 1 NIBCO

R

Ball V alve (PN: GB30)

14 1 8 Inch Long Nipple

15 1 90 Deg Elbow

Install a gas supply line that runs to the unit heating

section. Refer to the NFPA 54/NFGC or equivalent code

for gas pipe sizing data. Do not use a pipe smaller than the

size specified. Size the gas supply line to allow for a

maximum pressure drop of 0.5--in wg (124 Pa) between

gas regulator source and unit gas valve connection when

unit is operating at high--fire flow rate.

The gas supply line can approach the unit in two ways:

horizontally from outside the unit (across the roof), or

through unit basepan. Observe clearance to gas line

components per Fig. 19.

LEGEND

*

Field supplied.

NOTE: Follow all local codes.

NFGC – National Fuel Gas Code

STEEL PIPE

NOMINAL DIAMETER

(in.)

SPACINGOFSUPPORTS

X DIMENSION

(ft)

1

/

2

3

/

4

or 1

1

1

/

4

or larger

6

8

10

X

BASE UNIT

BASE RAIL

ROOF

CURB

9” MINIMUM CLEARANCE

FOR PANEL REMOVAL

MANUAL GAS

SHUTOFF VALVE

*

GAS

REGULATOR

*

48” MINIMUM

DRIP LEG

PER NFGC

*

FIELD-

FABRICATED

SUPPORT

*

FROM

GAS

METE

C11121

Fig. 19 -- Gas Piping Guide

580J-- 17-- 30--V

Loading...

Loading...