V. DEFROST

Defrost cycle is controlled by a thermistor which is located in the

fresh-air intake passage (the thermistor unit is connected to J4 of

control module (See Fig. 27 and 28). When defrost temperature

sensor detects the need for defrost, K5 relay will close for 6

minutes while K1 and K2 remain energized.

This closes the outdoor air damper while running HRV blower on

high-speed. This process recirculates warm indoor air through heat

recovery core which melts any frost that has formed. Water created

in this process is collected by HRV and drained away. Frequency

of the defrost cycle depends on outdoor temperature (see Table

10).

If defrost is not working properly, check for proper damper

operation. To do this, turn unit to OFF position. Damper should

close.

SAFETY FEATURE

This new control has an added safety feature. If microprocessor

does not detect the thermistor or detects a short circuit, unit will

automatically go intoa6minute defrost cycle every 20 minutes.

A. Defrost Check

1. Make sure defrost cable is properly connected into J4.

2. Make sure thermistor assembly is correct. Measure ther-

mistor temperature reading with multimeter. Select multi-

meter DC measurement scale 0-20v. At connector J4

(without removing thermistor cable), measure voltage be-

tween pins of thermistor cable. Depending on temperature

of outside air intake, values should correspond with those in

Table 9.

If reading is not correct (reading 0v for short circuit or 5v

for open circuit), change thermistor assembly.

3. If thermistor is good, do a RESET and see if defrost works.

If defrost still does not work, change circuit board.

B. Advanced Debugging

Defrost can be simulated using the following procedures:

1. Unplug unit from 115vac.

2. Disconnect thermistor assembly from J4.

3. Replug unit in 115vac and select high-speed exchange.

4. Defrost should start within 2 minutes after high-speed

exchange has been initiated.

5. After test unplug unit.

6. Connect thermistor cable to J4.

7. Replug unit back in 115vac.

VI. CONTROL MODULE JUMPERS

Jumpers on the control module give exact configuration to HRV

micro-controller. If there is a mistake in the jumper configura-

tion,it can cause improper unit operation. This control has a

simplified jumper selection mode. Jumper selection is done by the

presence or absence of jumper at specific location (See Tables 11

and 12).

WARNING: ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Always disconnect unit from 115vac prior to making any

jumper change. If unit is not disconnected, micro-

controller will never see jumper change.

VII. ERROR SIGNALING

Two types of error can be signaled by the wall control (automatic

wall control only). In case of error, indicators on wall control will

flash.

When error occurs, set dehumidistat at 80 percent position. This

will enable you to properly troubleshoot problems.

TYPE 1—LOSS OF MEMORY (AUTO MODEL ONLY)

All indicators flash rapidly (rate of about once every sec). When

this occurs, reset power and check if problem still exists. If

indicators are still flashing, check red wire for shorting on another

component. If error still exists, wall control has lost its memory.

Replace wall control.

The defective wall control still works even when flashing, it is

working in backup mode. Original modes of wall control are

replaced by backup mode (See Table 13).

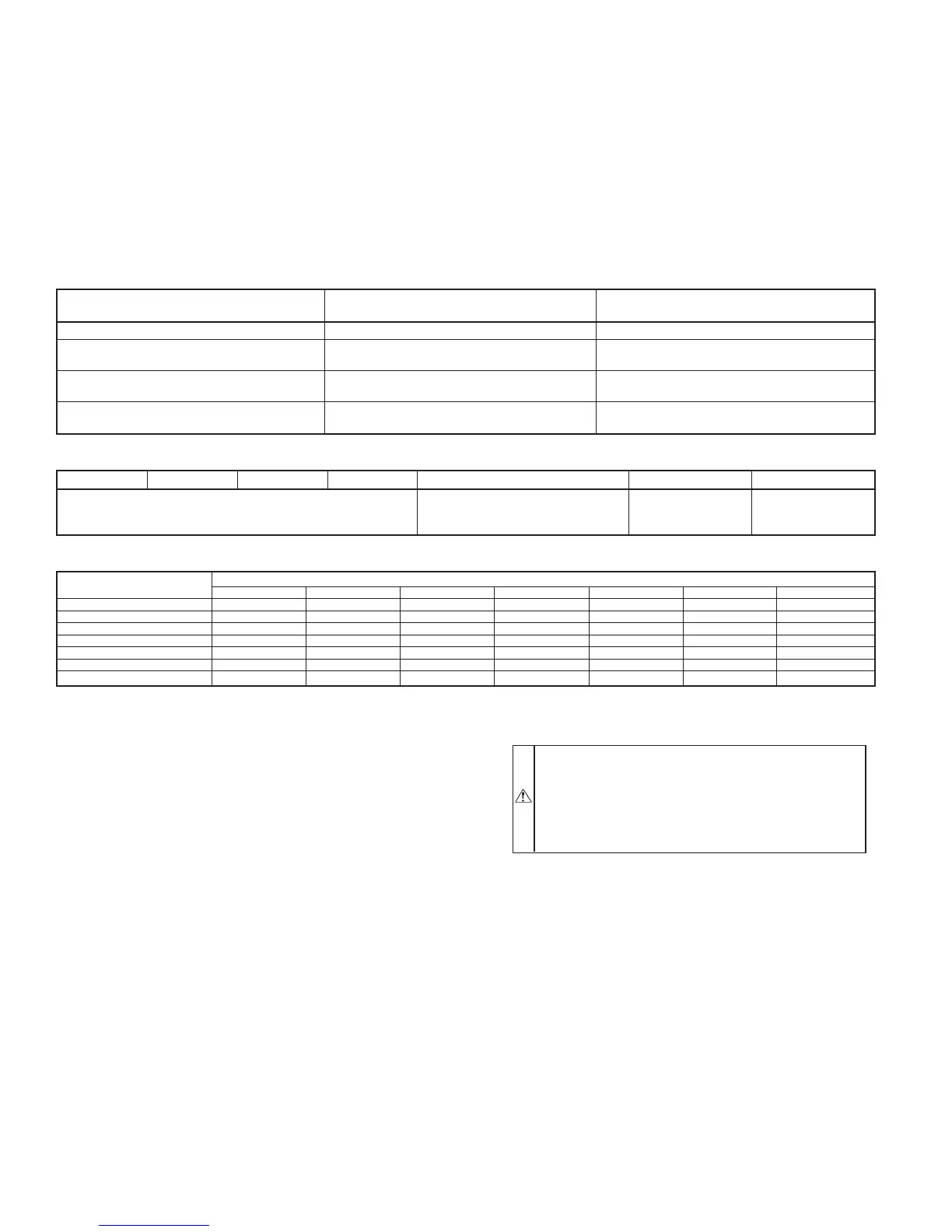

TABLE 10—DEFROST CYCLE

OUTSIDE TEMPERATURE °F

STANDARD DEFROST (AS

SHIPPED)

EXTENDED DEFROST

(JUMPER JU1-F REMOVED)

Above 23°F No Defrost No Defrost

23°Fto5°F

6 Minute Defrost/60Minute Ex-

change

10 Minute Defrost/30 Minute Ex-

change

4°F to -17°F

6 Minute Defrost/32 Minute Ex-

change

10 Minute Defrost/20 Minute Ex-

change

Below -18°F

6 Minute Defrost/20 Minute Ex-

change

10 Minute Defrost/15 Minute Ex-

change

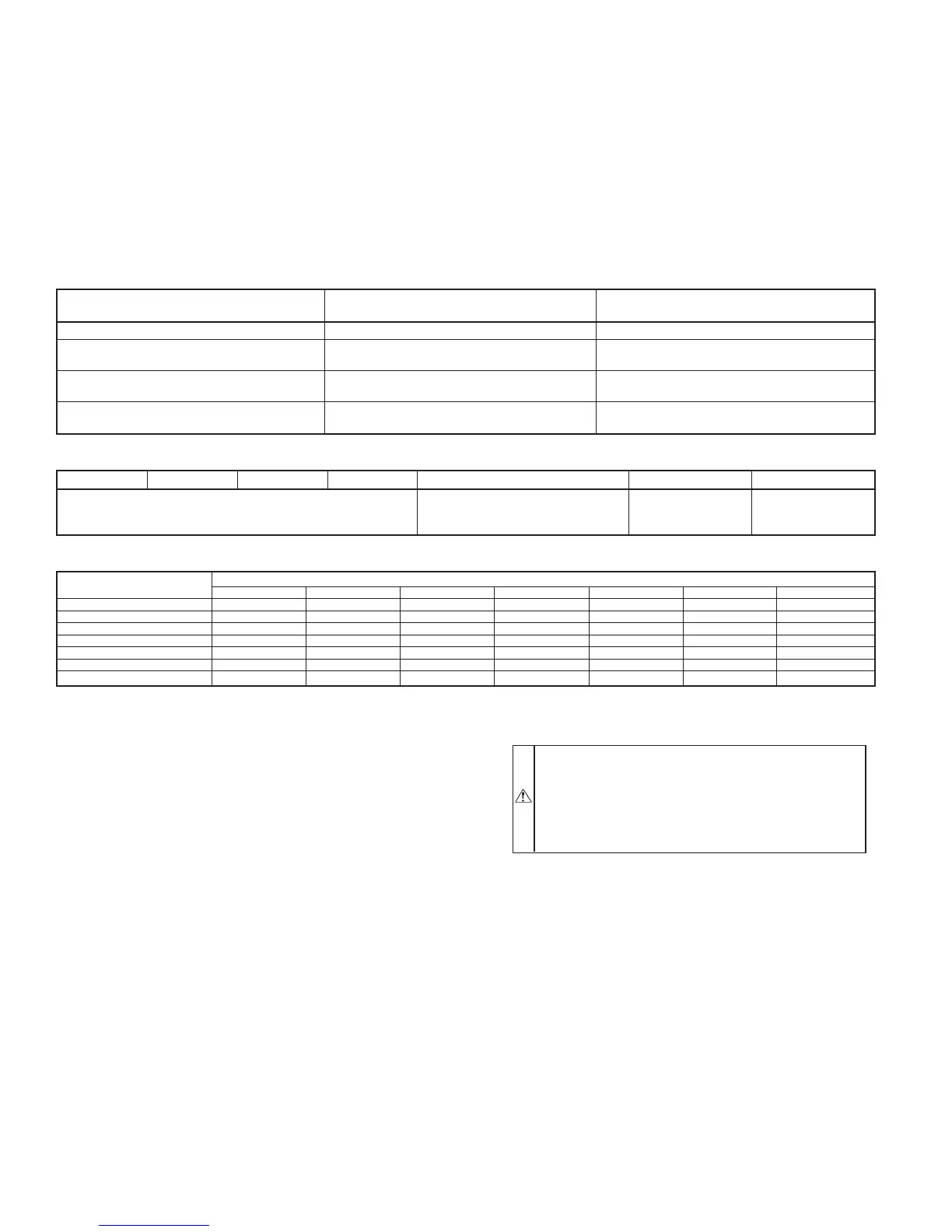

TABLE 11—JU1 JUMPER DEFINITION

JU1A JU1B JU1C JU1D JU1E JU1F JU1G

UNIT IDENTIFICATION

Reverse Damper Operation

In = Normal

Out = Inverse

Factory Set

Always In

Factory Set

Always In

TABLE 12—JUMPER LOCATIONS

MODEL

JUMPER TABLE

JU1A JU1B JU1C JU1D JU1E JU1F JU1G

HRVBBLHU1150 OUT IN IN OUT IN IN IN

HRVBBLHU1250 OUT IN IN OUT IN IN IN

HRVBBSVU1150 OUT OUT OUT OUT IN IN IN

HRVBBSVU1250 OUT OUT OUT OUT IN IN IN

HRVBBLVU1150 OUT OUT OUT OUT IN IN IN

HRVBBLVU1200 OUT OUT OUT OUT IN IN IN

HRVBBLVU1330 OUT OUT OUT OUT IN IN IN

—16—

Loading...

Loading...