I

the six

adjusting nuts are tighteDed equally

10 €Dsuro cveD

pr€ssure,

otherwise the

plates

will

slide

uDeveDly aod clutch

drag

will result. After the ådjustmetrt is

completed,

depr€ss

the

clutch

lever

and spin the clutch

by

operating

the

kickst4rter,

when the outer

plate

should

be

se€n to

tevolve

parallel

with the

other

plates.

If flot, adjust individual

r sDrinss until.the Dlates are true.

)

rtr:&frmy

Cfdl#(it*g.r modelsJ. The chajn

is

adjusted

by slackening the

two large nuts under the

gearbox,

one

on the left hand end

of

the

adjuster and one on

the

right-

hand side

(see

r,

Fig,

1l),

and screwing up the adjuster

nut E This draws

the

gearbox

rearwards, tightening the

chain. Donl forgel to tighten.ngil.P *ien.correct

lension is obtained, \r

hich should ,ilfow

half-an-inqh upt,r--

and down movement at the tisltest

polii6fT-e-iIåif,.

'- """

Ttr66-iE-at

after tighrening chiin. reår chain will

need

adjusting.

tul

'

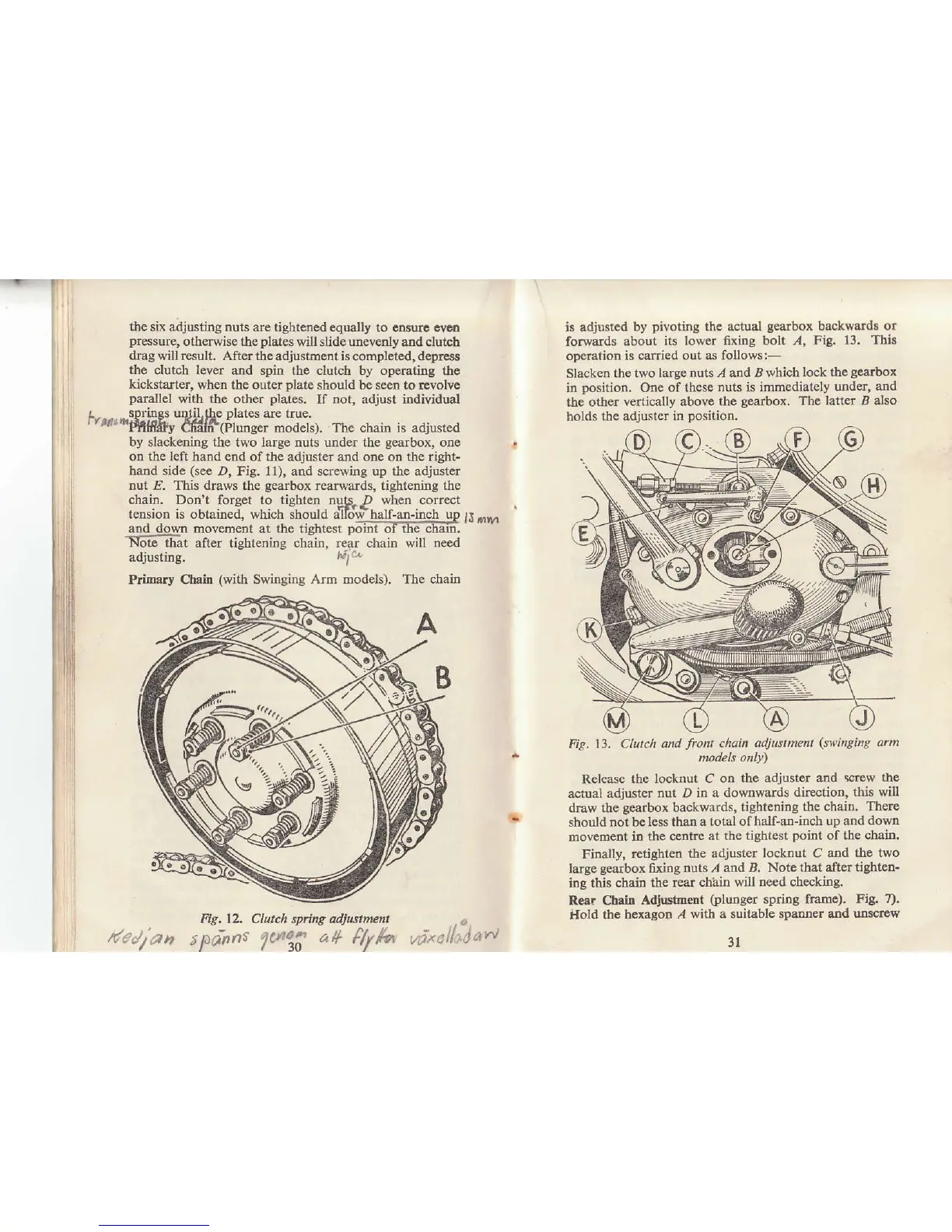

Flg.12.

Clutch spdng adJustment

E:o1'aa

tFrnnr

1cdttr

a*

l/y{ø

nixcil:isr't

is adjusted

by

pivoting

the actual

gearbox

backwards or

forwards about

its lower fixing bolt ,4,

Fig. 13.

This

operation

is carried out as follows:-

Slacken

the two

large nuts ,4 and ,B which

lock the

gearbox

in

position.

One

of these nuts is immediately

under,

and

the other

vertically above the

gea.rbox.

The

latter t also

holds

ihe adjuster in

position.

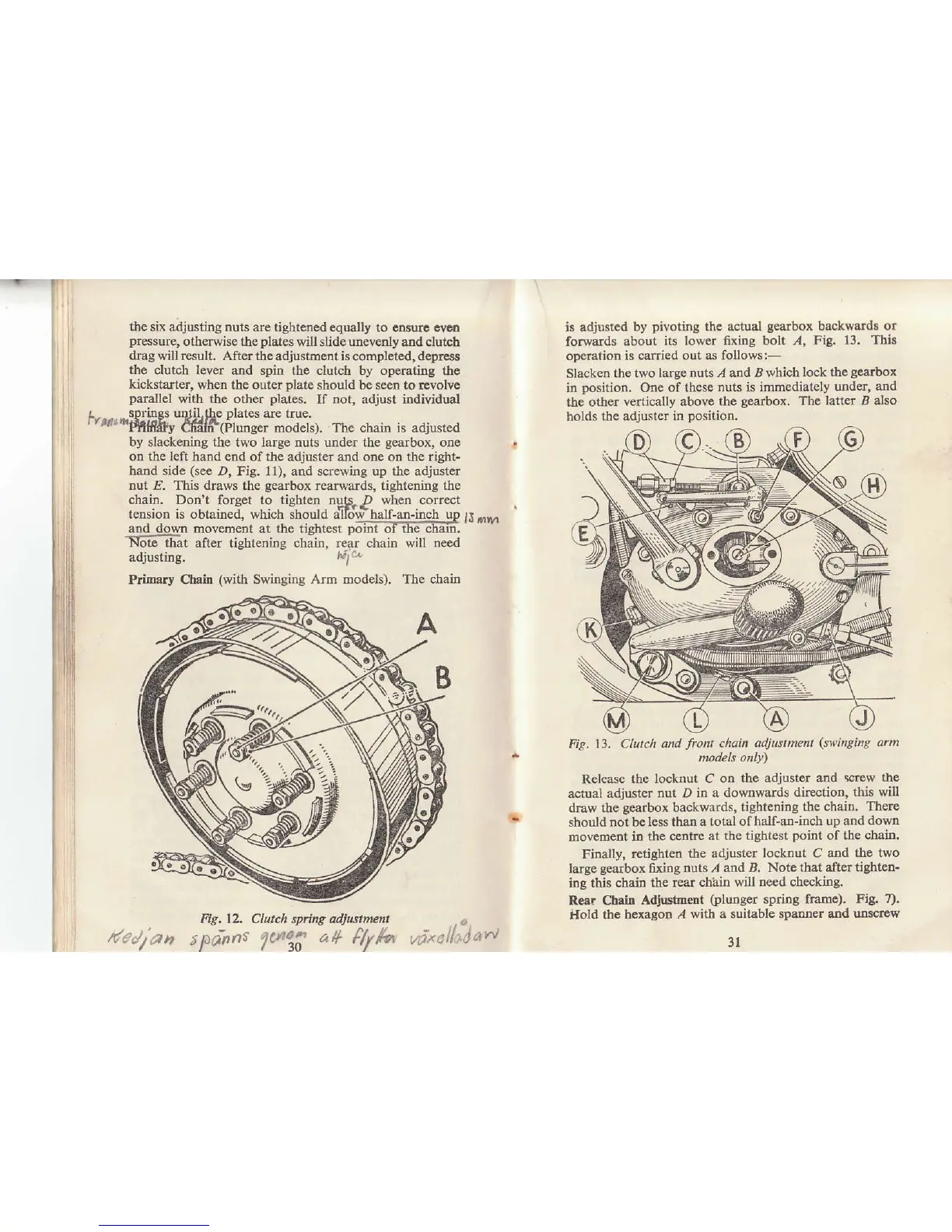

Fig.

13. Clutch and

front

ehain adjustment

(swinging

arm

models only)

Release

the locknul C

on the adjuster and

screw the

actual adjuster

nut D

in a downwards dircotion,

this will

draw the

gearbox

backwards,

tightening the

chaio. There

shoutd

not be less than

a total of half-an-inch

up and dowtr

movement

in the centle

at the tightest

point

of the chain'

Finally,

retighten the

adjuster locknut C and

the two

large

gearbox

fixing truts ,4

and

-&.

Note

that aJter tight€n-

ing this chain

the rea. ch?lin

will need checkiDg.

Rea. Chaitr

Adiustment

(plunget

spring frame).

Fig. 7).

ilold tbe

hexagon I

with a suitable spaDner and

uoscrew

PriEary

Chain

(with

Swinging Arm modeis), The

chain

Loading...

Loading...