should

be st€adied

to

prevent possible

damage. Whetr the

barrel

is remov€d,

cover the mouth of

the

craokcåse

with

rag to

prevent

rust and

gdt

falling

in. To reftove

the

piston

from

the connecting rod

it is

first

necessary to

take

out

one of

the

gudgeon pin

circlips.

This is best ac.om-

plished

with

a

pointed

instrument such as the tang

of

a

file suitably

ground.

Before the

gudgeon pin

can be withdrawn

it may be

necessary,

jf

the engine is cold,

to

heat

the

piston

with the

aid of rags

imme6ed in hot water,

wrung out, and held

round tlle

piston.

Then, supporting

the

piston,

tap

tbe

gudgeon

pin

through using

a light hammer and a

punch.

When the

piston

is free,

mark the inside of the

piston

skfut at th6 back,

so that it can be

replaced the corect

way rouod.

If the rings

are stuck in

the

grooves gleat

care will be

treeded to

pdse

them free and to

lemove them from the

piston.

All carbon

deposit should be

carefully scraped

from

the

grooves

and the

inside

edges

of the rings. If

eithe. of

the rings shows

brown

patches

on the face,

replace

with a new

qg.

Check

the

piston

ng

gap

by inserting

the

piston

in

the barrel

and sliding

each ling indcpendently

up to the

skiit

ofthe

piston,

check the

gap

with feeler

gauges,

and

this should

not

be

less than .008

in.

or

morc than .012 in.

Fit

new rings

if the

gap greatly

exoeeds the figure stated,

although

a few

thousandths of an

inch extra

gap

are not

serious. It

is advisable

to check the

gap

of new

dngs

before fitting,

and if the

gap

is less than .008 in, the

ends

of

the rings

should be carefully

filed to the corect

limit.

It

should be

noted that

piston

rings

are very britde,

and unless handled

carcfully a.e

easily broken. This

appties

palticula

y

to the søaper ring.

Re€ssembling.

When

the lings arc

refitted, replace the

piston

on tho connecting

rod

(see

that

it is the

right

way

round), smeår

the

gudgeon

pin

libe(ally with engine oil,

add

tap

into

position.

Then

refit the

Sudgeon

pin

circ[p.

Smear

the

pistor

liberally

witl clean eDgine oil; turn

thc dngs.

so that

tho

gaps

are on opposite sides of the

pistoo;

fit a ncrf, cylinda!

base washer on

the

cmnkcase;

liberElly c.at the inride

of the cylhder barrel wirh

clean

engine oil

aDd then, coEplessing the rings in

tum by

hand,

carefully slide the baEel i[to

position

over rhe

piston.

This operation will

be simplified if the

piston

rings ar€ compressed into their

grooves

by means of metal

bands, such as can be obtained from

accessory suppliers.

Next replace the valves into

their

respective

positions,

place

the springs over the stems

with the top collar iD

porition,

and with l,he head rsting on

wooden block

as

befor€, compress the springs until the split

collets can

be

inserted. A dab of

grease

on the inside

of the collets will

serve

to hold them in

position

u.til the spring is released.

Make

quite

sure that the

collets are corlectly located,

(For

Comp. and

Gold Star models see

pages

49

and 5l

respectively).

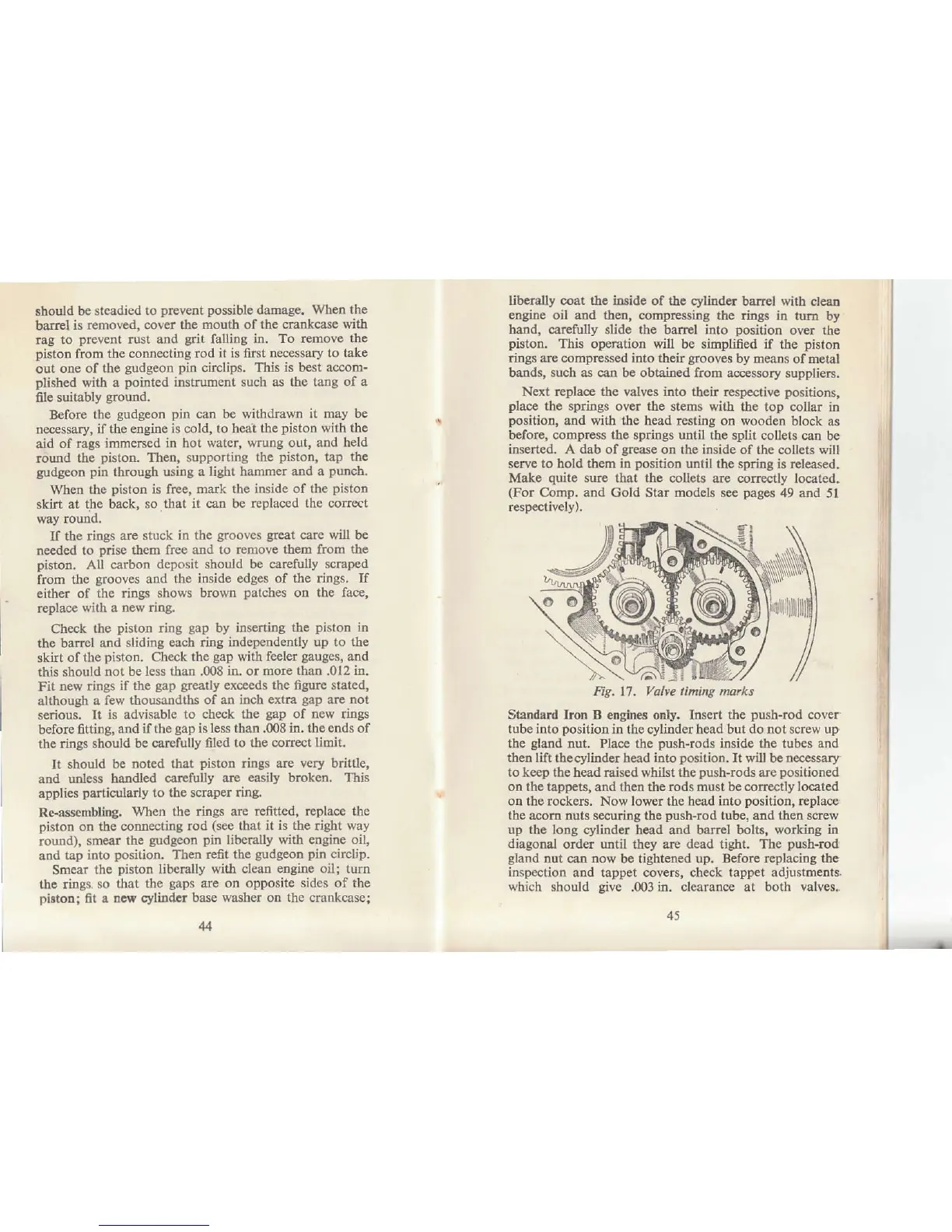

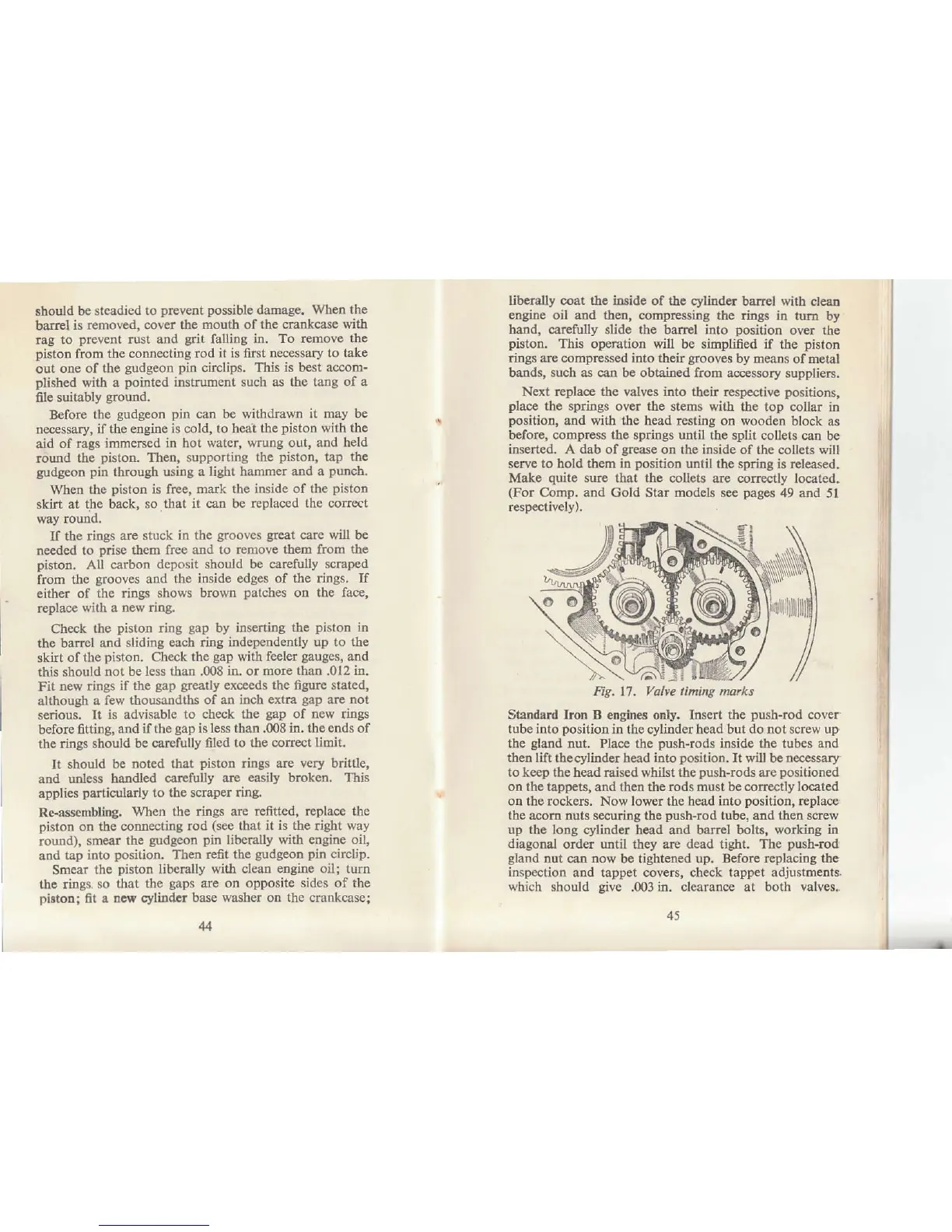

ng. 17. Valw

timing ,narks

Standard

kon B engines or

y.

Insert

the

push-rod

cover

tube into

position

iD

tho oylinder head

but do not screw up

the

gland

nut.

Place the

push-rods

inside the tubes

and

then lift the

cylinder

head into

position.

It will

be

necessary

to ke€p the head raised

whilst

the

push-rods

are

positioned

on the tappets, atrd then the rods must be corectly located

oq the rocke$. Now lorrer the head into

position,

rcplacc

the

acom nuts secudn8 the

push-rod

tube, add then screw

up the long

cylinder head and barrel bolts,

working in

diagonal orde! until

they

are deåd tight. The

push-rod

gland

Dut

can

dow

be tightened

up. Before replacing the

inspection

and tappet covers, check

tappet adjustments.

which should

give

.@3

in. clearance at both valves.

i

I

ij

I

I

I

Loading...

Loading...