thc

spindle slightly

by means ofa

to@ny bar at C.

Slacken

ofr the hexagoD B on

the

left-hand

side of

the hub dren

screw

the

adjusters D in

or out as the case may

be, until

the

chain

tensioD is correct, with not

less than

i

in. total

up-and-do\rn

movement,

at the ceDtre of the

bottom run

of the

chain

*itlr the machine

oD its central stand.

so

that

the

rear

wheel is in its lowest

positiotr.

Resr Chain

Adiurboe[t

(Comp.

and

Swinging Arm

models). Uascrqw

the spindle

4

Fig.

8,

slightiy

with a

tomDy bar then slacken

ofr the hexagon ,4 oD the

left

hand

side

of the hub, Release

the locknuts C and søew

the

adjusters D

in

or out as the

case may be, until the

chain ten3ion

is correct, with not less

than I

I

in.

(Comp.

l

in.) total

up-and-down movemeDt at

the centre of the

bottom ru!

of ihe chaio.

To

allow

for any variation in

chain tensioD the

wheel

should be rotated by hand until

the

tightest

pointis

fouad,

with the wheel in

its

lowest

positiotr.

Front Brake Adiustmeot

The

lenSth

ofthe

brake cable can

be altered at its lower end

by means of a knurled thumbnut

on the cable stop,

(For

Gold Står Racing,

see HaDdlebar

lcvers,

page

57.)

Resr Brake Adiustment

Finger adjustment is

provided

at

the end

of brake rod.

Do not

set the blakes too closely, since,

particularly

in

tho case of the

front brake,

its

action may

be

too

power{ul.

Any friction

between

lining

and drum will obviously

impair the macbine's

pedomanc€.

In addition, if carded

to extremes, the heat may

melt the

grease

in the hubs

and

this may find its way to the

brak€

linhgs.

(For

lub cation

see

page

16.)

Centralising

(7in.

Brakes only). Slacken the nut

on thc

brake cover

plate,

thus loosening the fulcrum

pin

in its

slotted hole. Apply brake,

when

fulcrum

pin

will auto-

matically

c€ntralise the assembly, and

keeping lhc brake

on, finally lock

up the nut.

(See

also

page

19.)

Brrkc

Crm Spindlcs. Thesc

arc

lubricated

with oil scc

fugc

lli.

32

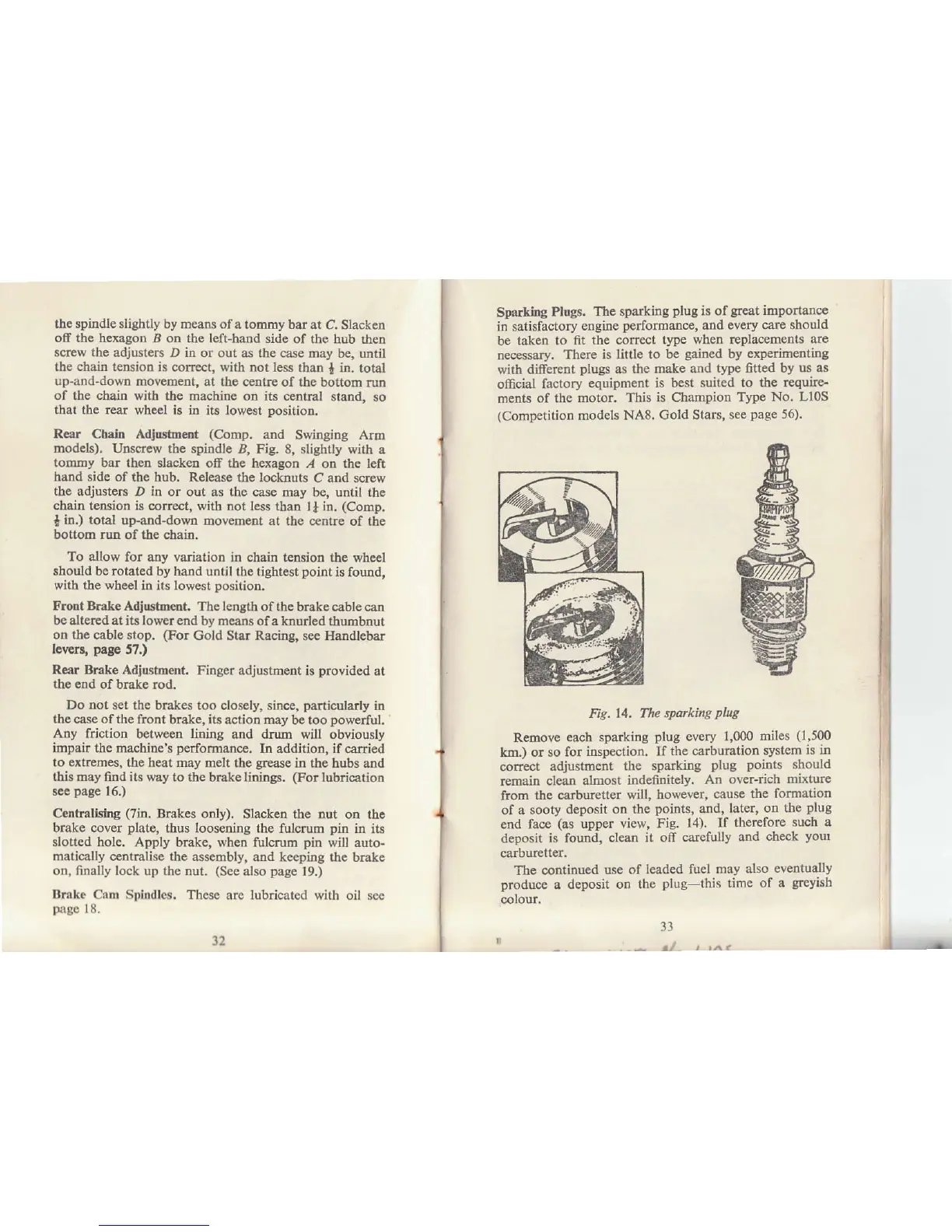

Sprking

Plugs.

The spdking

plug

is of

Sleat

importance

in satisfactory

engine

perfomalce,

and every

care should

be taken

to fit

the

correct

type when

replacements

arc

necessary.

There

is little 1o be

gained

by experimenting

with

different

plugs

as

the make and

twe fitted by

u$ as

official factory

equipment is best suited

to the rcquire-

ments

of the motor.

This is Champion

Type No. L10S

(competition models NA8.

Gold Stars, see

page

56).

Fis.14, The

spa*ing

plug

Remove

each sparking

plug

every 1,000

miles

(1,500

km.)

or so for

idspection. lf

the carbu.ation

system

is in

correct

adjustment

the sparking

plug

points

should

Emain clean

ahnost indefinitely.

An

ovel- ch

mixtwe

fiom

the carburetter

will, however,

cause

the fomation

of a sooty

deposit on the

points,

and,

later, on the

plug

end face

(!s

upper view, Fig.

14). If

thereforc

such a

deposit

is found, clean

it off carefully

and

check

your

carbuletter.

The continued

use of

leaded fuel

may also

evettually

produce

a

deposit on

the

plug-this

time of

a

geyish

colouf.

3l

Loading...

Loading...