-

A liSht

deposit

due to

any of these

causcs

can easily

be

cleaned

off, but if

it is

allowed to

accumulate,

particularly

inside the

body,

the

ptug

may spark

internally with

an

adverse

effect

on engine

perfoftnanc€-if,

indeed, ir does

not stop

the

engine

altogether.

The

plugs

should

be

cleaned

and resled

at regllar

interuals,

and

it is suggested

rnar rhrs

servtce

be

pertbrmed

at

your garage

on a special

'Air Blast'service

unit.

lfeventually

the

cleaning

process

Ialls to

restore

lhe

plug

!o

ils

original

condition

of

emcieDcy,

it should

be

replaced

by a new

one.

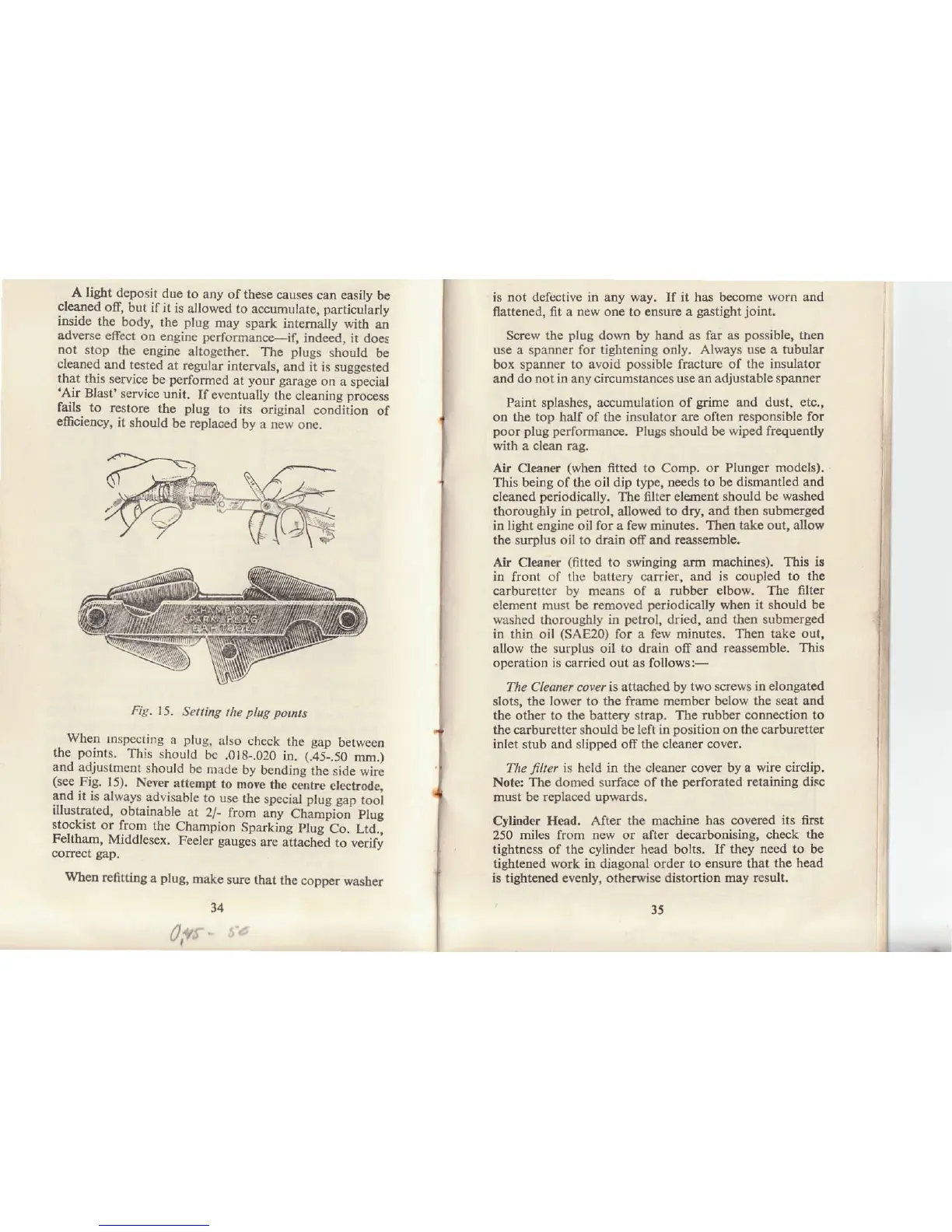

Fig. 15.

Sc

ing the

plug

pornrs

.

When

lnsp€oting

a

plug.

also check

the

gap

between

the

poinrs.

This

shoutd

be .018-.020

in.

(.45_.50

mm.)

and adjustment

should

be

made by

bending

the side wiri

Gee

Fig.

l5).

Neyer åtfempt

to moye

Oc

centre

electuode,

and it is

alwaJs

ad'"isable

to

use lhe

special

plug

gap

rooi

lrusrmteo.

obtalnatrle

at 2/_

trom

any

Champion

plug

stockist

or

from lhe

Champion

Sparking

plug

Co. Ltd.

Felrham,

Middlesex.

Feelei

gauges

are

atrached

to vcrify

conect

gap.

When

refittinS

a

plug,

make

slrle that

the

copper warsher

0;t:,

34

35

is

not defective in

any

way.

If

it has become worn and

flattened,

fit a new one to €nsure a

gastightjoillt.

Screw

the

plug

down

by hand

as far as

possiblq

then

use

a spanner for tightening only. Always use a tubular

box

spanner to avoid

possible

fiact$e of the insulator

and

do notin any

circumstances

use an adjustable spanner

Paint splashes, accumulation of

grime

and dust- etc.,

on tle top half of the insulator are

often responsible for

poor plug pcrformance.

Plugs should

be wiped fre4uenlly

with a clean rag.

Air

Cleån€r

(when

fitted to

Comp.

or Plunger

models).

This being of the oil dip typc, needs to be

dismantled and

cleaned

periodically.

The filter ele&ent

should be washed

thoroughly in

petrol,

allowed to dry,

and then submerged

in light engine oil for a few minutes.

Then take out, allow

the surplus oil to drain of and .eassemble.

Atu

Cleåner

(fitted

to swinging arrn machhes). This

is

in

front

of lhc battery cårrier, and is coupled

to the

carburetter by means of a rubber

elbow. The filter

element must be remov€d

periodicålly

when it should be

washed thoroughly

in

petrol,

dried, and then submerged

in thin oil

(SAE20)

for

a

few

minutes. Theo take

out,

allow the surplus oil

to drain

ofr and

reassemble.

This

operation

is

carried out

as

follows:-

The Cleaner cover is attached by

two sqews in elongated

slots, the lower to the frame member

below the seat and

the

other

to the

battery

strap. The rubber connection to

the

carburetter

should

be

left in

position

on the carburetter

inlet

stub and

slipped off the cleaner cover.

The

ltlter

is

held

in the cleaDer cover by a wire circlip.

Note:

The domed surface of the

p€rforated

retaining

disc

must be

replaced upwards.

Cylinrler

Head. After the machine

has covered its 6rst

250

miles

from

new or after decarbonising, check

the

tightness

of the

cylinder head

bolts.

If they

need to

be

tightened work in diagonal order to ensure that

the head

is tightened evenly, otherwise distortion may result.

Loading...

Loading...