Location

The ISOMET™ 2000 Precision Saw is intended for bench-top

placement. Select a location with convenient access to electrical and

water services.

Electrical

All units operate with a universal requirement range from 85-264V

50/60 Hz AC Input. Appropriate cord for country of use is supplied.

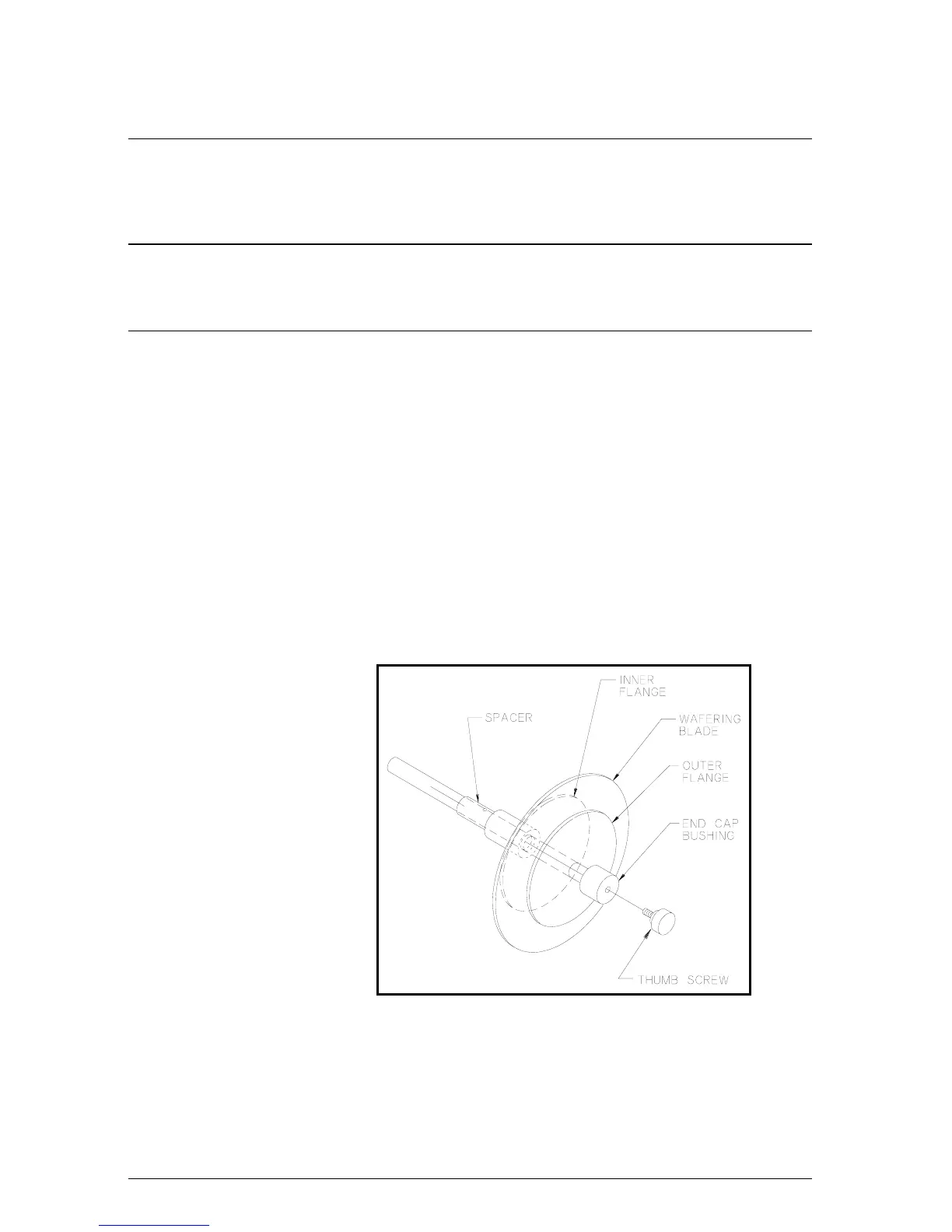

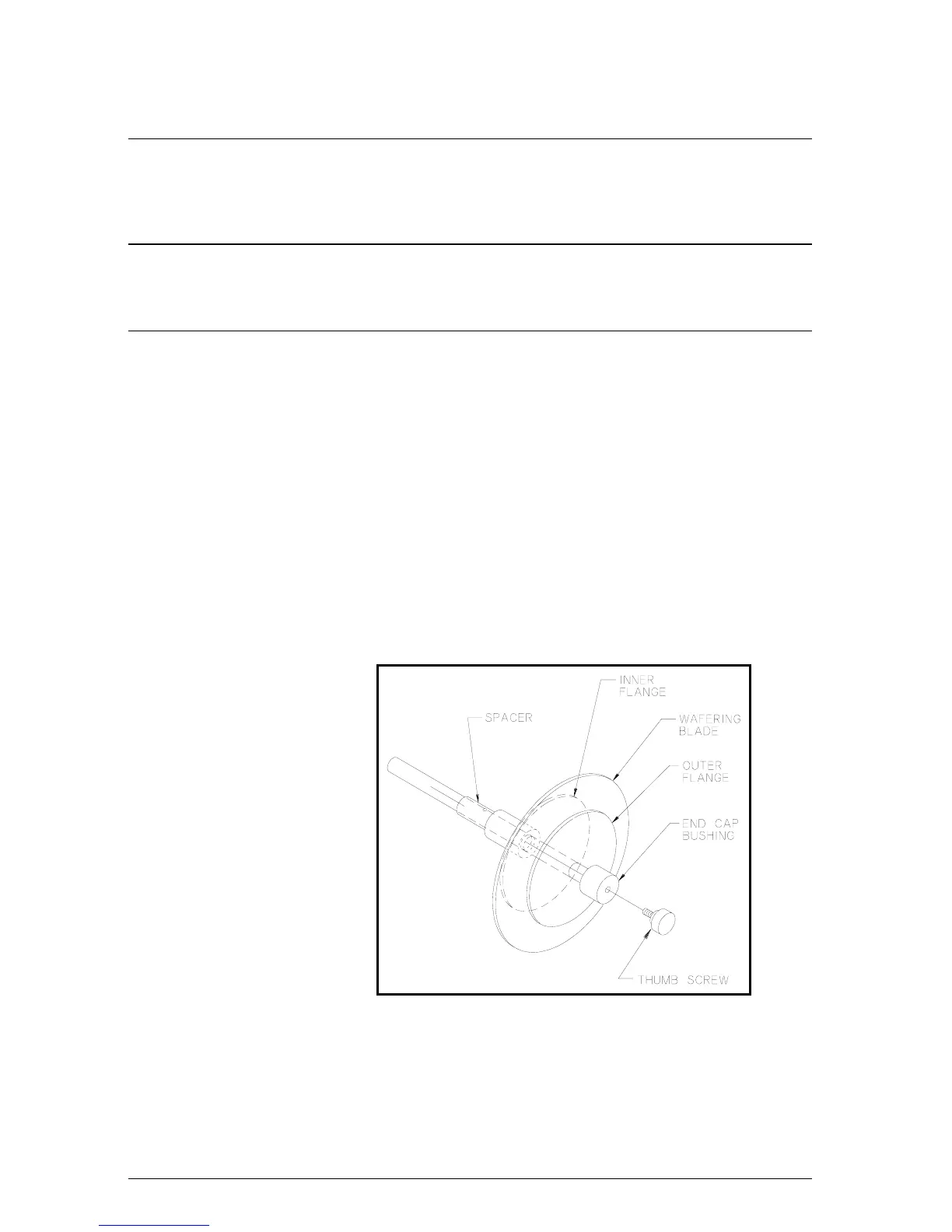

Blade Installation

Flanges support the Wafering and Abrasive Blades. Failure to provide

adequate flange support may result in curved cuts and damaged

blades. Always select the maximum flange diameter commensurate

with the size of the specimen to be cut. (See Accessories and

Supplies.)

1. Remove Thumb Screw and End Cap Bushing from Drive Shaft.

2. Install the Inner Flange on the Drive Shaft.

3. Install the blade against the inner Flange.

4. Slip on the Outer Flange and End Cap Bushing, then hand

tighten Thumb Screw to complete installation.

NOTE Before installation of a Wafering or Abrasive Blade, the End Cap

Bushing, Screw and Flanges should be cleaned in a mild detergent

solution to remove adherent particles from prior cutting. This will

prevent misalignment and damage to the Blade.

Figure 2 Blade Installation

Blade Dressing

New wafering blades, including the original equipment blade, must be

dressed before making sample cuts. Dressing removes the normal

smeared matrix metal and exposes the abrasive grain to assure free

cutting. New wafering blades should be dressed several times and

3

MA112480-20 03/06/00

Loading...

Loading...