7 | Maintenance

14 / 24 0870169526_KB_KC0010-0016E_A0004_IM_en

7.1 Maintenance Schedule

The maintenance intervals depend very much on the individual operating conditions. The

intervals given below are desired to be considered as starting values which should be

shortened or extended as appropriate. Particularly harsh applications or heavy duty oper-

ation, such as high dust loads in the environment or in the process gas, other contamina-

tion or ingress of process material, can make it necessary to shorten the maintenance in-

tervals significantly.

Interval Maintenance work

Weekly

• Check the oil level, see Oil Level Inspection [►14].

• Check the machine for oil leaks - in case of leaks have

the machine repaired (contact Busch).

Monthly In case of an inlet filter being installed:

• Check the inlet filter cartridge, replace if neces-

sary.

Every 2000 hours, at the latest

after 6 months

• Change the oil and the exhaust filters (EF).

Every 5 years • Have a major overhaul on the machine (contact

Busch).

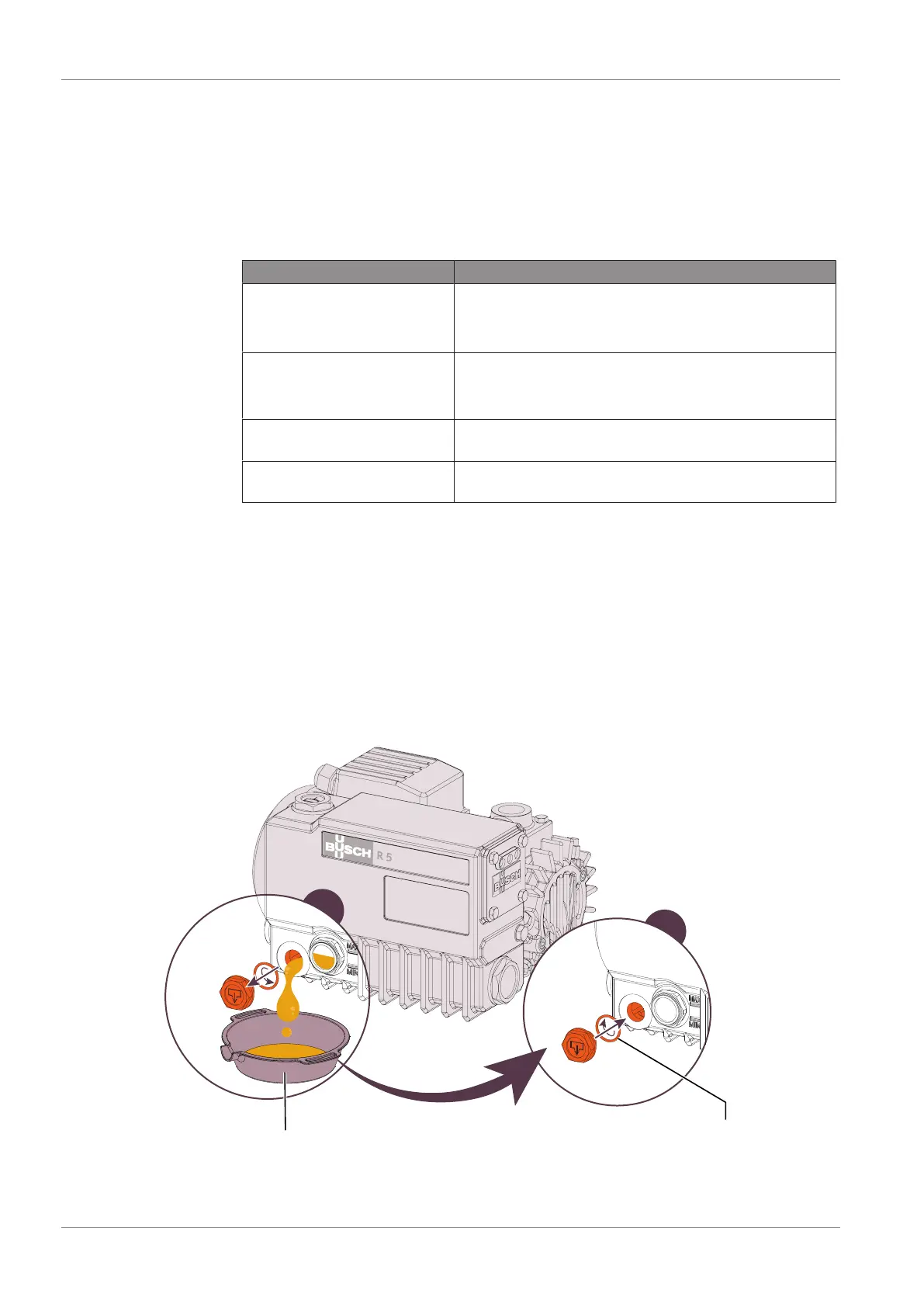

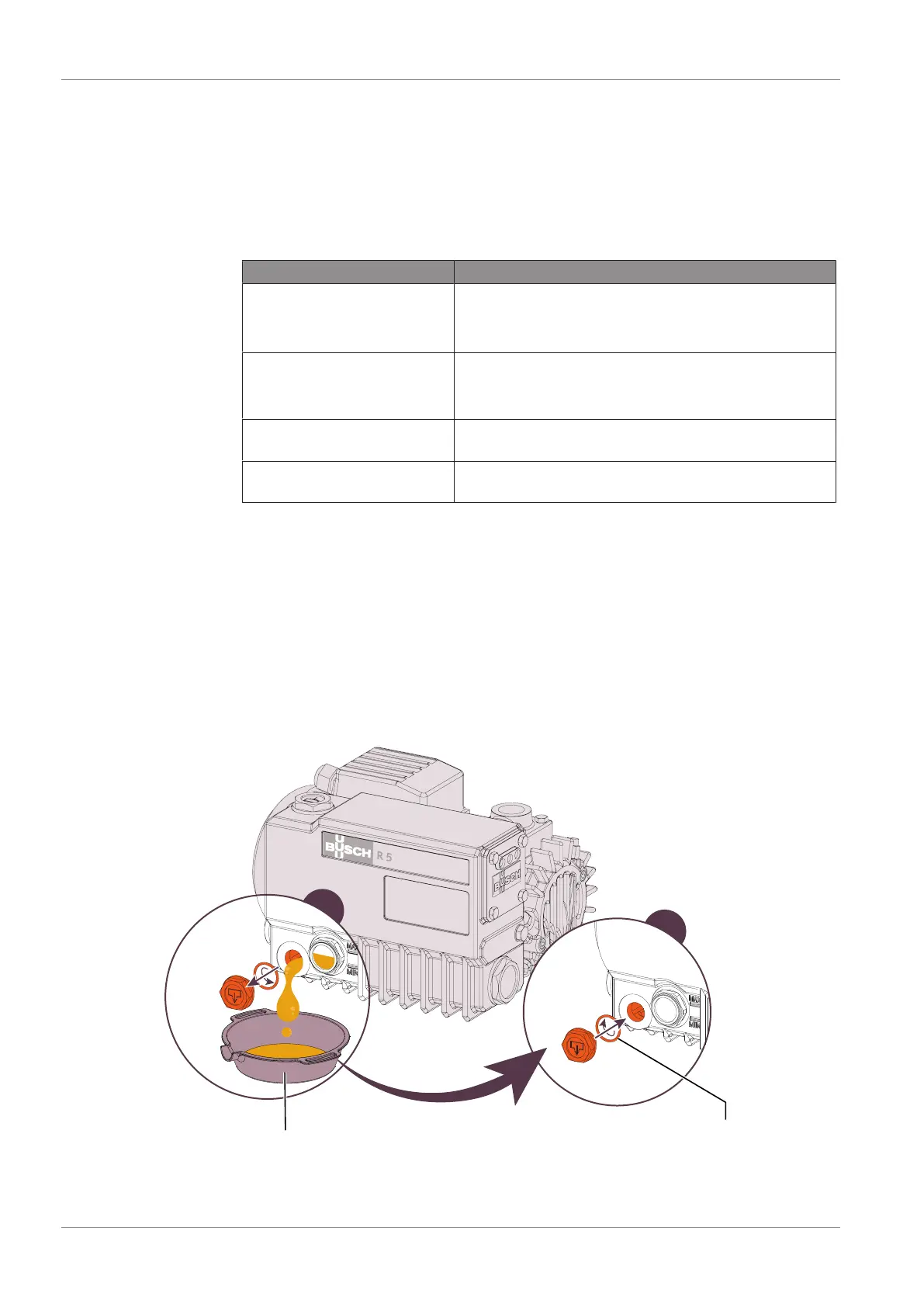

7.2 Oil Level Inspection

• Shut down the machine.

• When the machine is stopped, wait 1 minute before checking the oil level.

• Fill up if necessary, see Oil Filling [

►9].

7.3 Oil Change

Drain pan

1x o-ring, part no.:

0486 000 505

Loading...

Loading...