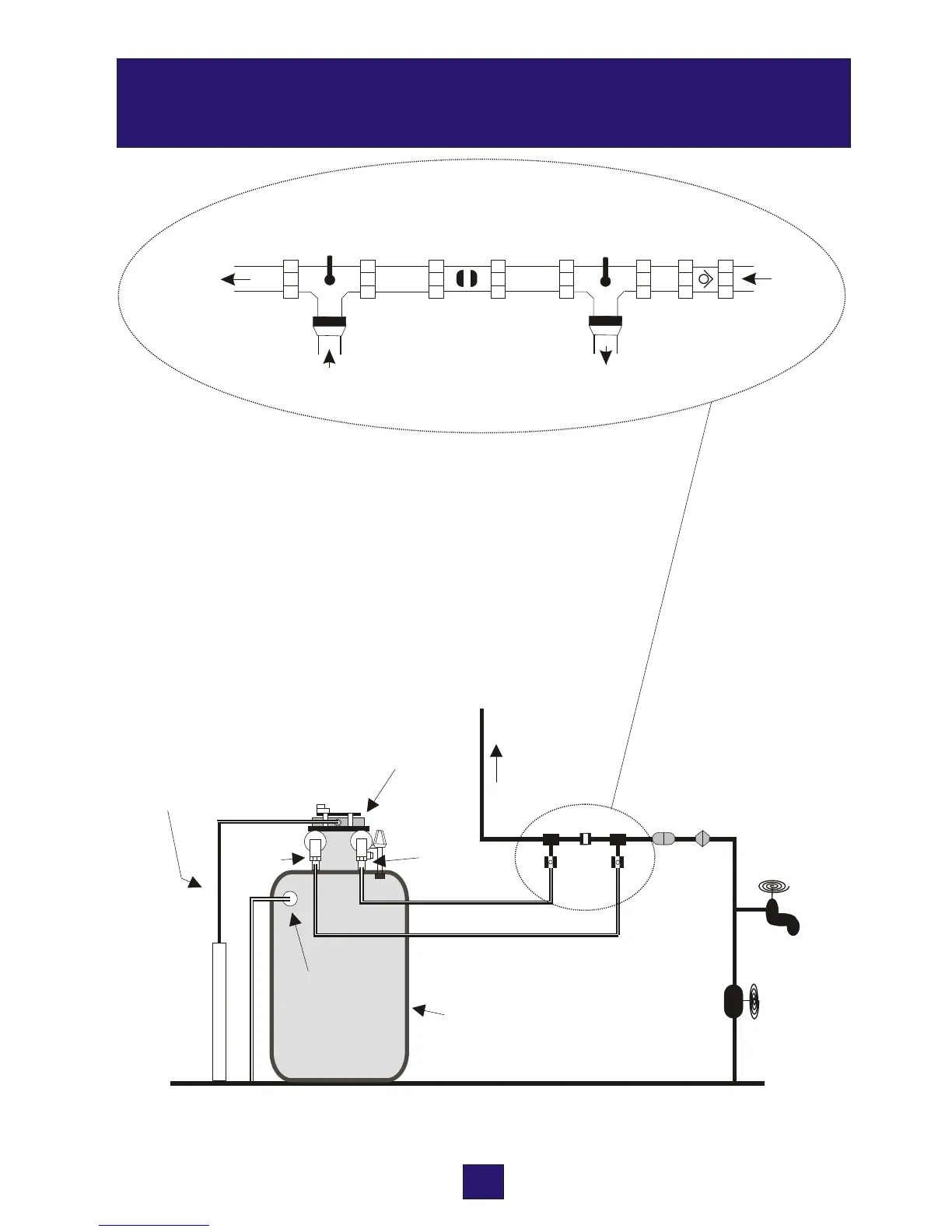

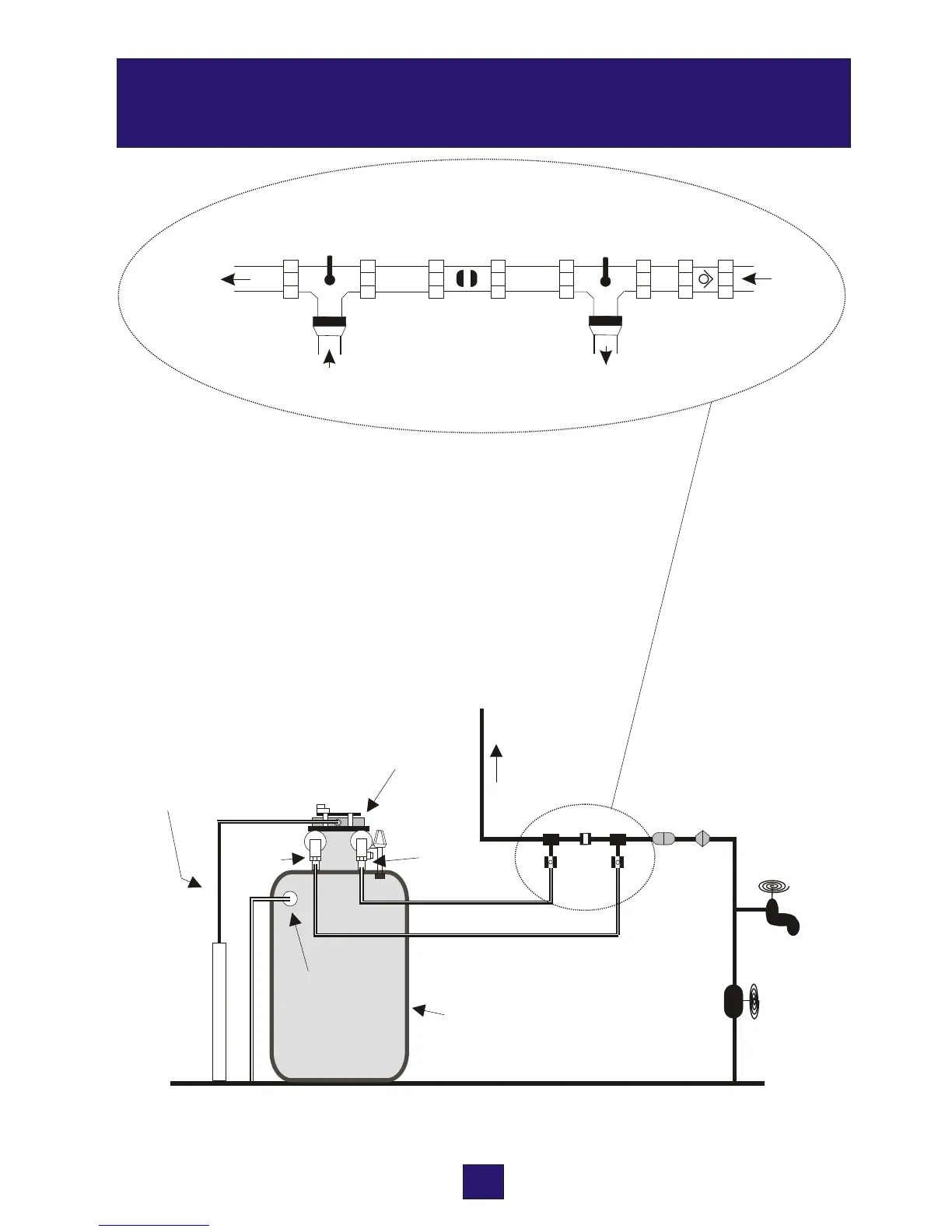

Key to the diagram

A. Non return valve

B. Pressure reducing valve (where required)

C. Inlet valve

D. Bypass valve

E. Outlet valve

6

N

P

A

R

T

O

E

A

B

C

E

D

Mains stop valve

Drinking

water

Drain hose

Overflow*

Valve Head

Brine

Cabinet

Inlet

Outlet

Rising Main

* The overflow must discharge to a place that is visable outside the building.

INSTALLATION LAYOUT

7

PART TWO

INSTALLING YOUR WATER SOFTENER

It is very important to establish the water pressure before installing the water softener. If

the water pressure is low then the water softener may not operate effectively. If it is too

high, then components inside the unit may be damaged.

Water pressure should be tested with a gauge at the kitchen tap or outside tap.

It should be noted that water pressure can increase at periods of low water usage e.g.

overnight. If therefore, the daytime pressure exceeds 5 BAR or if you are unsure

about pressure, then a pressure-limiting valve should be fitted.

Where the pressure is less than 1.7 BAR a booster pump may be required.

2. Inlet and outlet connections

1. Positioning the water softener

With the bypass valve open and the inlet / outlet valves closed the unit can be connected

to the plumbing system. Arrows on the inlet and outlet piping from the valve will confirm

the direction of flow.

Connections can be made in one of three ways - where high flow rates are not required

(static head systems) these connections can be made using the standard flexible hoses

supplied with your softener, ensure the hoses are not kinked as this may restrict flow. For

systems requiring higher flow rates (those fitted with combination boilers or unvented

pressurised systems) the connections should be made using specialist high flow hoses

supplied with a HI-FLO softener, or conventional copper tube and fittings.

3. Drain connection

Push the flexible drain hose onto the barbed connector (Drain) as shown on page 6 and

secure with the clip provided. Run the drain hose to a stand pipe or to a drain. The air gap

needs to be at least 20mm . Softened water will have no adverse effect on a septic tank.

You can extend the drain up to 9m if you have sufficient pressure (greater than 3 BAR).

The drain hose must not be kinked or restricted in any way as this will cause an overflow

from the brine cabinet.

Frost protection

o

If the drain hose or connecting pipework is likely to be subject to temperatures below 0 C it

must be protected to prevent freezing. Failure to observe this precaution could lead to the

water softener overflowing.

Raising the drain hose

If you have a water pressure of 3 BAR or more, you can raise the drain to a maximum of 3

metres above the valve head.

P

A

T T

W

O

R

Outlet valve

shown open

By-pass valve

shown closed

Inlet valve

shown open

Outlet from

softener

Inlet to

softener

Inlet from

mains

Non-return

valve

To rising

main

Loading...

Loading...