COLLEGAMENTO ABBINATO I MATCHING CONNECTIONS I BRANCHEMENT ACCOUPLE

KOMBIANSCHLUSS/CONEXI6N COMBINADA

c

10N

SON

MORSETTlERA

"OlORE

2

-K'TDR

2

TERMINAL BlOCK

PLAQUE

it.

BORNE! MClEUR 2

KlEMMBRETT MOTOR

2

CUADRO DE BORNES MOTOR

2

...•

- -

.

".

"Slave"

"Master"

[101

1__

1

~~ZP10

~ 111111

I

[101

1__

1

m

", :~ZP10

I

111111

I

J

MORSEITJERA

..aTOM 1

MOTOR

1

TERMIIVAl BlOCK

PLAQUE

A

BORNE! MOTEUR

1

KlEMMBRErT MOTOR

f

CUADRO DE BORNES MOTOR

1

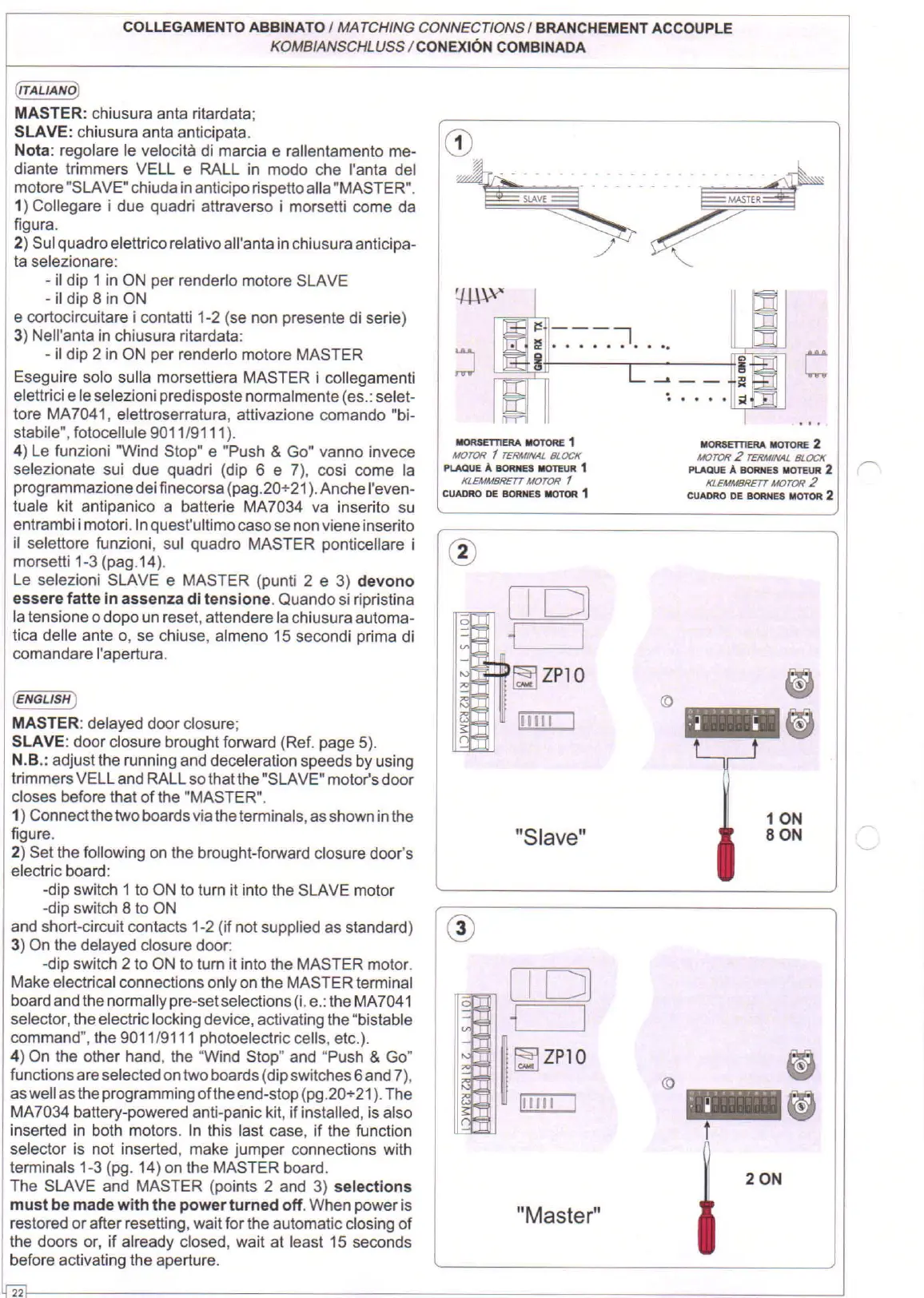

(ITALIANO)

MASTER: chiusura anta ritardata;

SLAVE: chiusura anta anticipata.

Nota: regolare Ie velocita di marcia e rallentamento me-

diante trimmers VELL e RALL in modo che I'anta del

motore "SLAVE" chiuda in anticipo rispetto alia "MASTER".

1) Collegare i due quadri attraverso i morselli come da

figura.

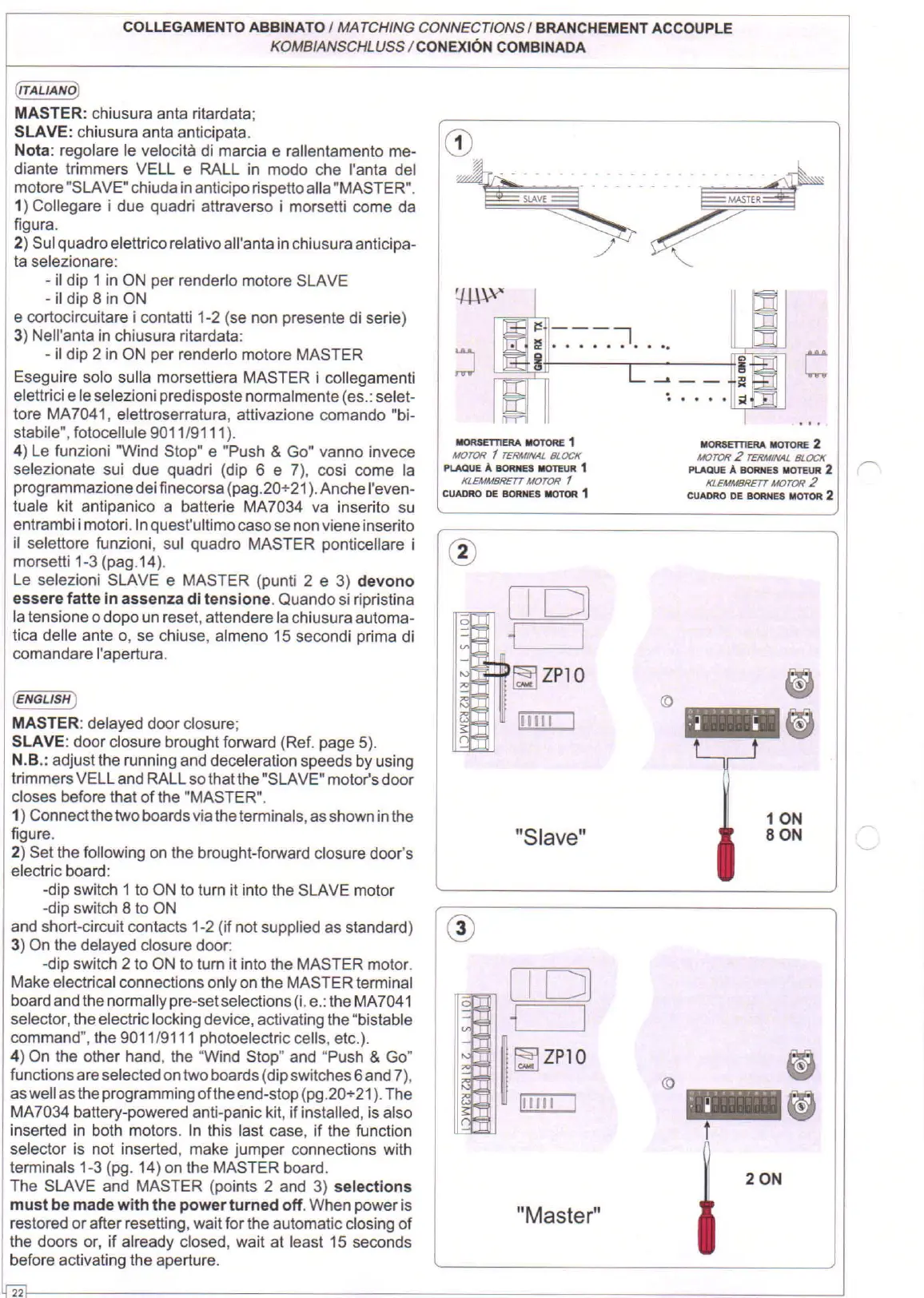

2) Sui quadro elellrico relativo all'anta in chiusura anticipa-

ta selezionare:

- il dip 1 in ON per renderlo motore SLAVE

- iI dip 8 in ON

e cortocircuitare i contalli 1-2 (se non presente di serie)

3) Nell'anta in chiusura ritardata:

- iI dip 2 in ON per renderlo motore MASTER

Eseguire solo sulla morsetliera MASTER i collegamenti

elellrici e Ie selezioni predisposte normalmente (es.: selet-

tore MA 7041, elellroserratura, allivazione comando "bi-

stabile", fotocellule 9011/9111).

4) Le funzioni "Wind Stop" e "Push & Go" vanno invece

selezionate sui due quadri (dip 6 e 7), cosi come la

programmazione dei finecorsa (pag.20+21). Anche I'even-

tuale kit antipanico a ballerie MA7034 va inserito su

entrambi i motorl.lnquest'ultimo caso se non viene inserito

iI selellore funzioni, sui quadro MASTER ponticellare i

morselli 1-3 (pag.14).

Le selezioni SLAVE e MASTER (punti 2 e 3) devono

essere fatte in assenza di tensione. Quando si ripristina

la tensione

0

dopo un reset, allendere la chiusura automa-

tica delle ante

0,

se chi use, almeno 15 secondi prima di

comandare I'apertura.

(ENGLISH)

MASTER: delayed door closure;

SLAVE: door closure brought forward (Ref. page 5).

N.B.: adjust the running and deceleration speeds by using

trimmers VELL and RALL so that the "SLAVE" motor's door

closes before that of the "MASTER".

1) Connect the two boards via the terminals, as shown in the

figure.

2) Set the following on the brought-forward closure door's

electric board:

-dip switch 1 to ON to turn it into the SLAVE motor

-dip switch 8 to ON

and short-circuit contacts 1-2 (if not supplied as standard)

3) On the delayed closure door:

-dip switch 2 to ON to turn it into the MASTER motor.

Make electrical connections only on the MASTER terminal

board and the normally pre-set selections (I. e.: the MA7041

selector, the electric locking device, activating the "bistable

command", the 9011/9111 photoelectric cells, etc.).

4) On the other hand, the "Wind Stop" and "Push & Go"

functions are selected ontwo boards (dip switches 6 and 7),

aswell as the programming of the end-stop (pg.20+21). The

MA7034 ballery-powered anti-panic kit, if installed, is also

inserted in both motors. In this last case, if the function

selector is not inserted, make jumper connections with

terminals 1-3 (pg. 14) on the MASTER board.

The SLAVE and MASTER (points 2 and 3) selections

must be made with the power turned off. When power is

restored or after reselling, wait for the automatic closing of

the doors or, if already closed, wait at least 15 seconds

before activating the aperture.

"

Loading...

Loading...