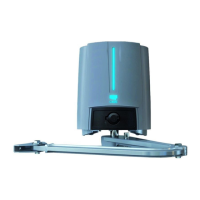

What to do if CAME Gate Opener gates are open but will not close and green LED is flashing?

- RRonald McneilAug 3, 2025

If your CAME Gate Opener is stuck open with a flashing green LED, here’s what you should check: * Make sure the safety beams are wired correctly. If you have multiple sets, they must be wired in series. * Confirm that the safety beams are receiving power. If not, restore it. * If safety beams aren't installed, ensure a hard wire link connects terminals 2 & C1. * Remove the safety beam wires from terminals 2 & C1 on the control panel and check for a normally closed circuit coming from the beams.