Documentazione

Tecnica

S45

rev. 2.2

07/2002

©

CAME

CANCELLI

AUTOMATICI

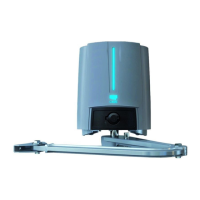

FROG A

CANCELLI AUTOMATICI

SCHEDA COMANDO

CONTROL BOARD

CARTE DE COMMANDE

STEUERPLATINE

TARJETA DE MANDO

ITALIANO/ ENGLISH/ ESPAÑOL

119AS45-1

SERIE FROG |

FROG SERIES

|

SERIE FROG

8

6

5

2

4

7

10

9

3

1

9

1

10

3

4x1,5

3x1,5

230V

4x1

2x1,5

RG58

3x1

5x1

2x1

4x1

RX

TX

RX

TX

4x1,5

2x1

11

10

1 - Gruppo FROG

2 - Quadro comando incorporato

3 - Fotocellule di sicurezza

4 - Ricevitore radio

5 - Selettore a chiave

6 - Antenna di ricezione

7 - Pulsantiera interna

8 - Lampeggiatore di movimento

9 - Colonnina per fotocellula

10 - Scatola di derivazione per cavo

motoriduttore (é consigliabile fare le

connessioni del cavo

motoriduttore in scatole di deriva-

zione)

11 - Trasmettitore radio

Impianto tipo Instalación tipo

1 - Conjunto FROG

2 - Cuadro de mando incorporado

3 - Fotocélulas de seguridad

4 - Radiorreceptor

5 - Selector mediante llave

6 - Antena receptora

7 - Pulsadores de interior

8 - Lámpara intermitente de movimento

9 - Columna para fotocélula

10 - Caja de paso para el cable del

motorreductor (se aconseja hacer las

conexiones del cable del

motorreductor en cajas de paso)

11 - Transmisor

Standard installation

1 - FROG unit

2 - Control panel (incorporated)

3 - Safety photocells

4 - Radio receveir

5 - Key-operated selector switch

6 - Antenna

7 - Internally located pushbutton arry

8 - Flashing light

9 - Photocell column

10 - Connector block for gearmotor cable (it is

advisable to make gearmotor cable

connections within connector blocks).

11 - Radio transmitter

Automazione per cancelli a battente (montaggio interrato)

Automatic opening system for wing gates (underground installation)

Automatizacion para puertas batientes (montaje en el terreno)

Cables de alimentación motores:

2 x 1.5 mm

2

hasta 20 m

2 x 2.5 " " 30 m

Cables de conexión microinterruptores:

3 x 1mm

2

Power wires to motor:

2 x 1.5 mm

2

up to 20 m

2 x 2.5 mm

2

up to 30 m

Wiring for microswitches:

3 x 1 mm

2

Cavi di alimentazione motori:

2 x 1.5 mm

2

fino a 20 m

2 x 2.5 mm

2

fino a 30 m

Cavi di collegamento microinterruttori:

3 x 1 mm

2

FROG A24