15

Model 288A Differential Pressure Indicating Switch Section 3

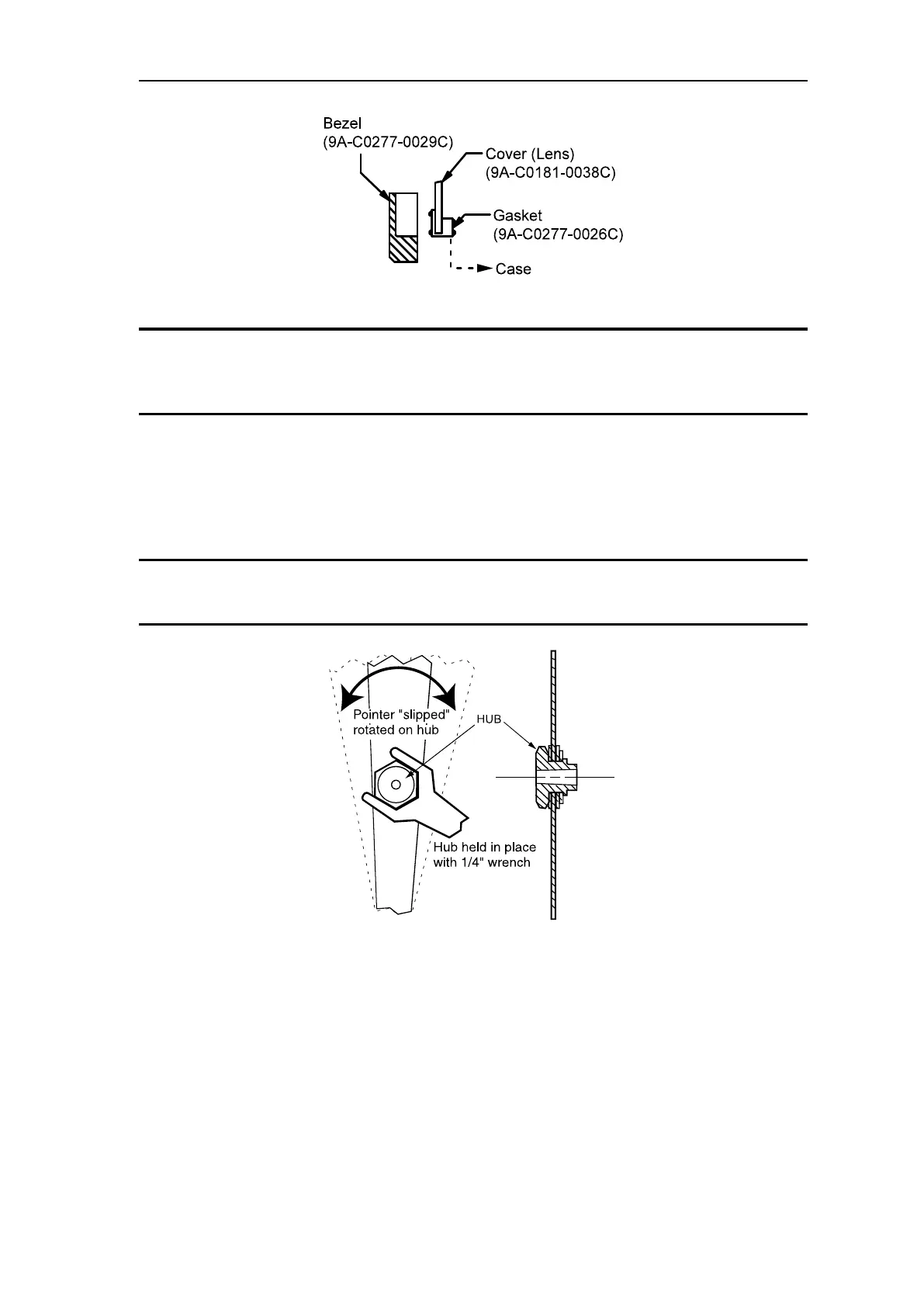

Figure 3.1—Bezel and lens cover

IMPORTANT: Ensure the bezel gasket is properly oriented before placing the instru-

ment back in service. Incorrect gasket orientation will cause the instru-

ment indicator to jam, resulting in inaccurate readings.

Calibration Check

To ensure the unit calibration is within factory-set calibration tolerances,

perform the following procedure.

IMPORTANT: Review all procedures, WARNINGS/NOTICES in Appendix A BEFORE

performing this procedure.

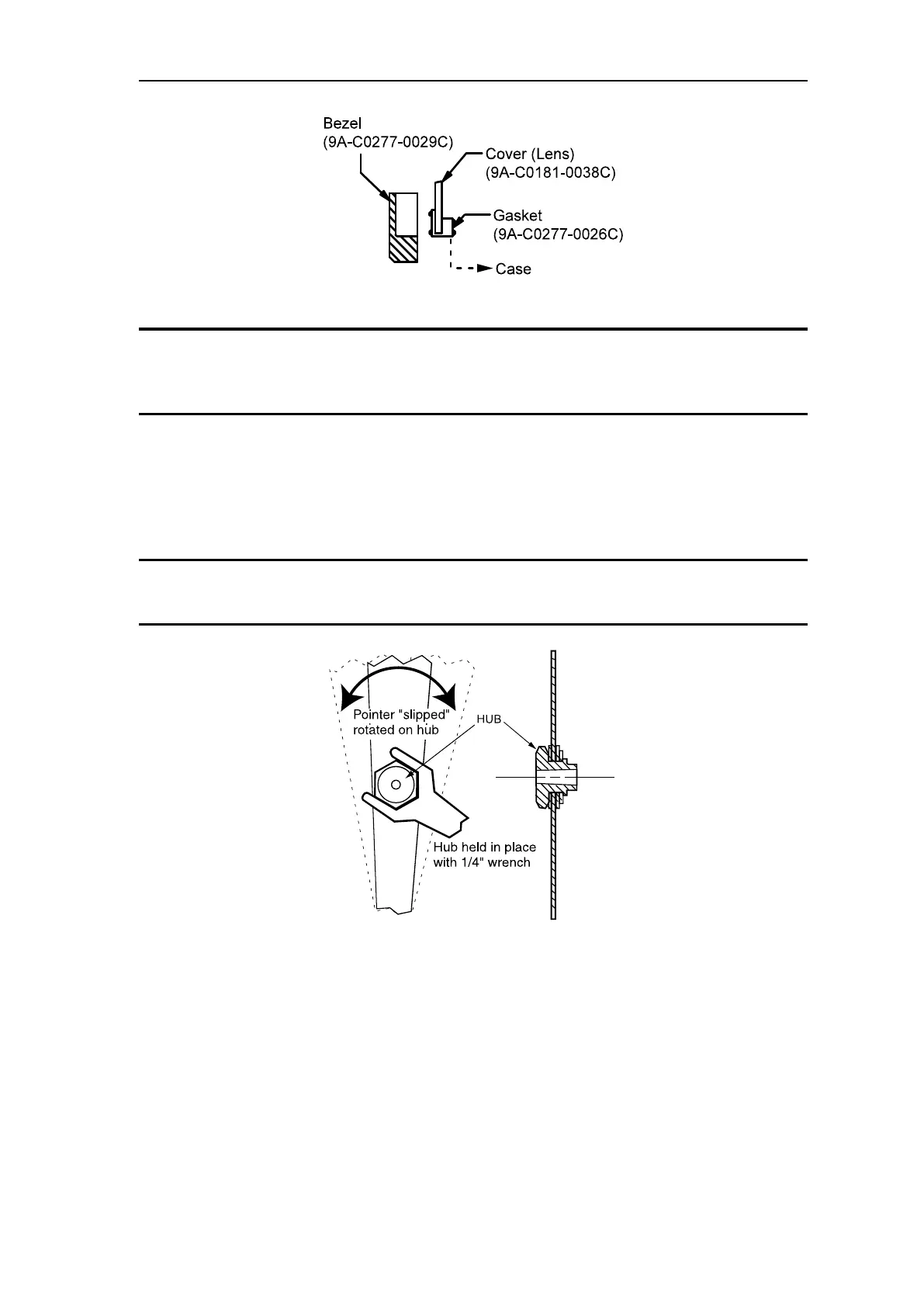

Figure 3.2—"Slipping" pointer

1. Mount the instrument in an approximately level position and connect to a

standard pressure source (see Mounting, page A-5).

2. If the zero indication is incorrect, adjust it as follows:

a. Remove the bezel/lens assembly.

b. Using a 1/4" open-end wrench (included in calibration toolkit, Part

No. 9A-0288-1032B), hold the hexagon pointer hub fi xed and rotate

the pointer with fi ngers until the pointer indicates zero on the scale.

See Figure 3.2.

c. Replace the bezel/lens assembly.

Loading...

Loading...