E N G L I S H

µC

2

- +030220731 - rel. 1.2 - 26.10.2007

7. CONNECTIONS,ACCESSORIES AND OPTIONS

7.1 Connection diagram

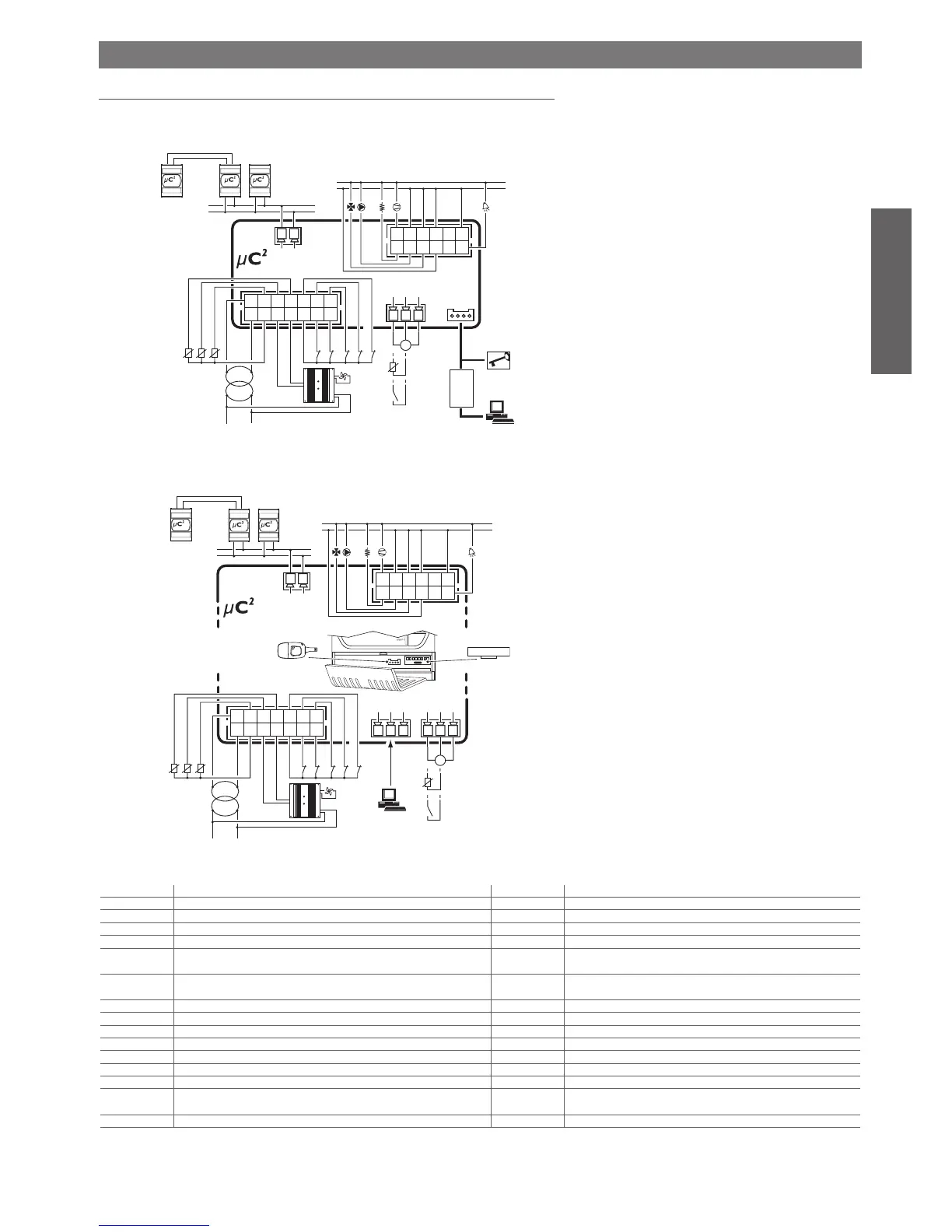

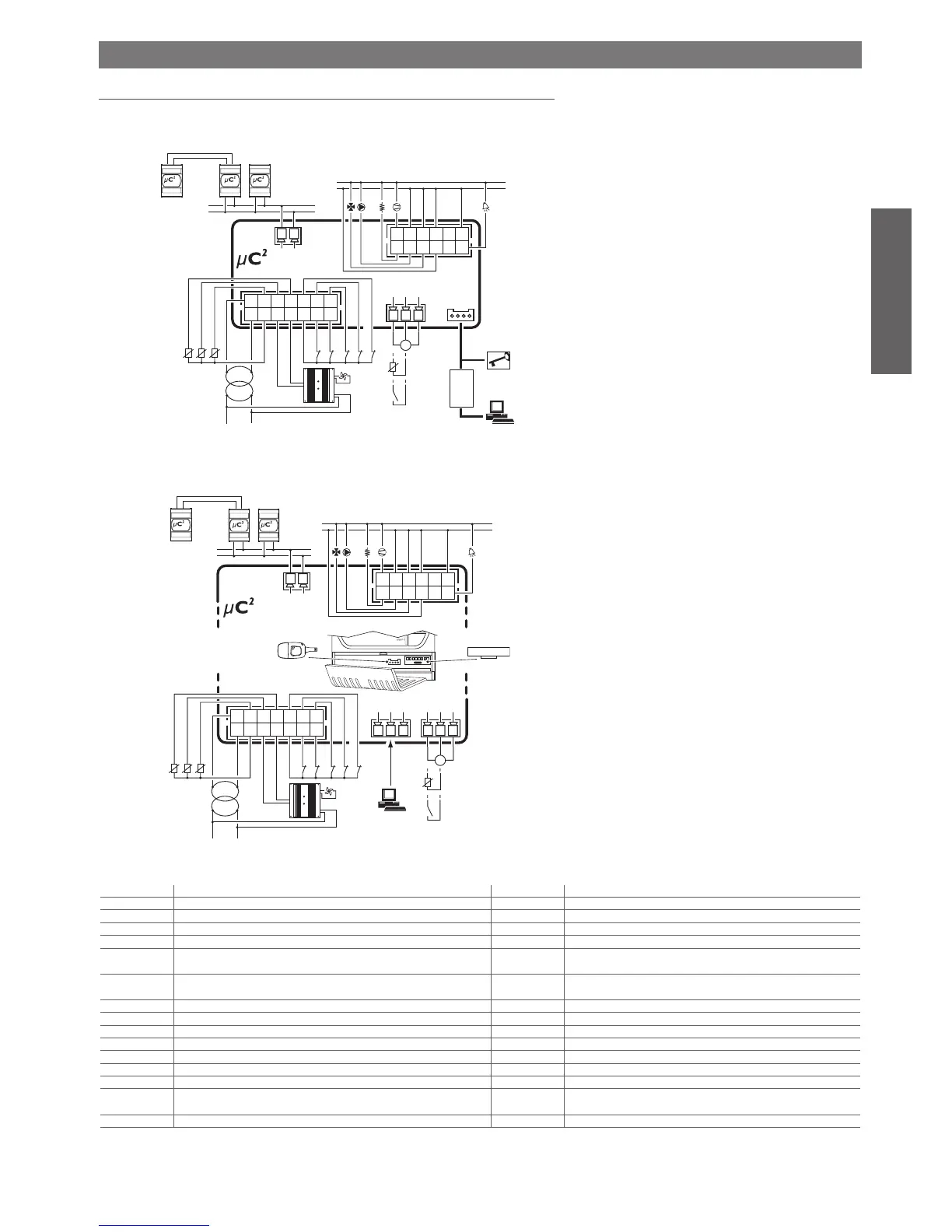

The following figure shows the connection diagram for the µC2, in the panel and DIN rail versions.

Panel version

Fig. 7.a

DIN rail version

Fig. 7.b

I/O layout

µC

2

Description Expansion Description

B1 Control probe (Evaporator inlet/ambient) B5 Output probe in common with 2 evaporators (only with 2 circuits)

B2 Protection probe (evaporator outlet/outlet) B6 Circuit 2 protection probe (2

nd

evaporator output)

B3 Condenser/outside temperature probe

B7 2

nd

condenser temperature probe

B4 (universal) Condenser pressure probe B8 (universal) 2

nd

condenser pressure probe

ID1* Flow switch – thermal overload circuit 1 – cooling/heating – end defrost circuit

1 – step 1 condensing unit – second set point

ID6** Flow switch – thermal overload circuit 2 – end defrost circuit 2 – step 4

condensing unit – second set point

ID2* Flow switch – thermal overload 1 circuit – cooling/heating – end defrost circuit

1 – step 2 condensing unit – second set point

ID7** Flow switch – thermal overload circuit 2 – end defrost circuit 2 – step 4

condensing unit– second set point

ID3 High pressure circuit 1

ID8 High pressure circuit 2

ID4 Low pressure circuit 1 ID9 Low pressure circuit 2

ID5 Remote ON/OFF – reverse cycle condensing unit if reversible ID10

Y1 Ramp circuit 1 (condenser) Y2 Ramp circuit 2 (condenser)

C1/2-NO1 Compressor 1 C6/7-NO6 Compressor 3 (1 in 2nd circuit)

C1/2-NO2 Heater or reversing valve in 1st circuit C6/7-NO7 Heater or reversing valve in 2nd circuit

C3/4-NO3 Fan 1/evaporator pump

C8/9-NO8 Fan 2/condenser pump/backup

C3/4-NO4

Compressor 2 (capacity-control compressor 1) C8/9-NO9 Compressor 4 (capacity-control compressor 2) or reversing valve circuit 1

or reversing valve circuit 2

C5-NO5 Alarm or reversing valve C10-NO10 Warning or reversing valve circuit 2

Table 7.a

*= Any of the options for P08 can be selected (see Table 5.11)

**= Any of the options for P08 can be selected, except for E/I and E/I delay.

Loading...

Loading...