96

ENG

µchiller +0300053EN rel. 2.2 - 14.12.2021

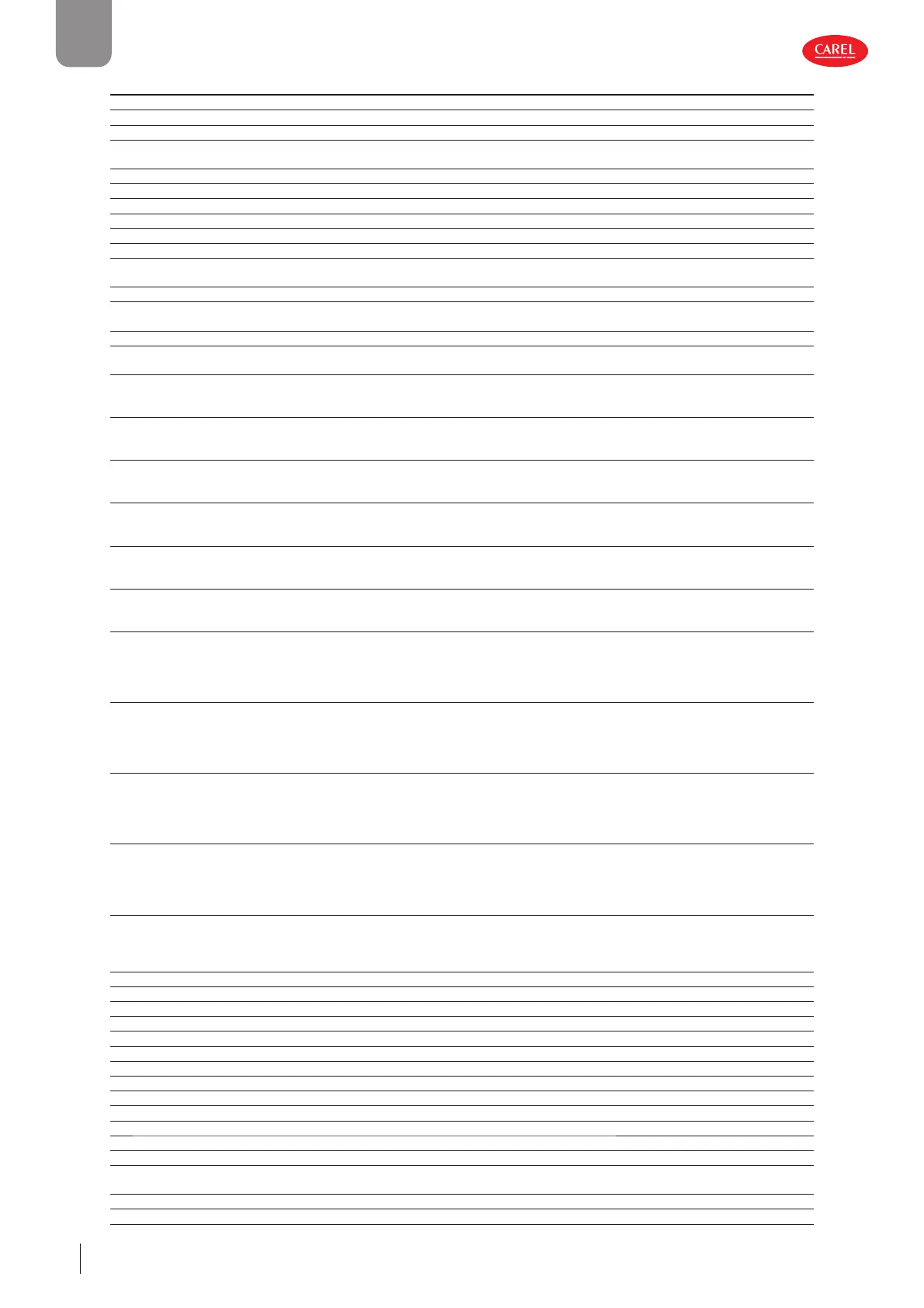

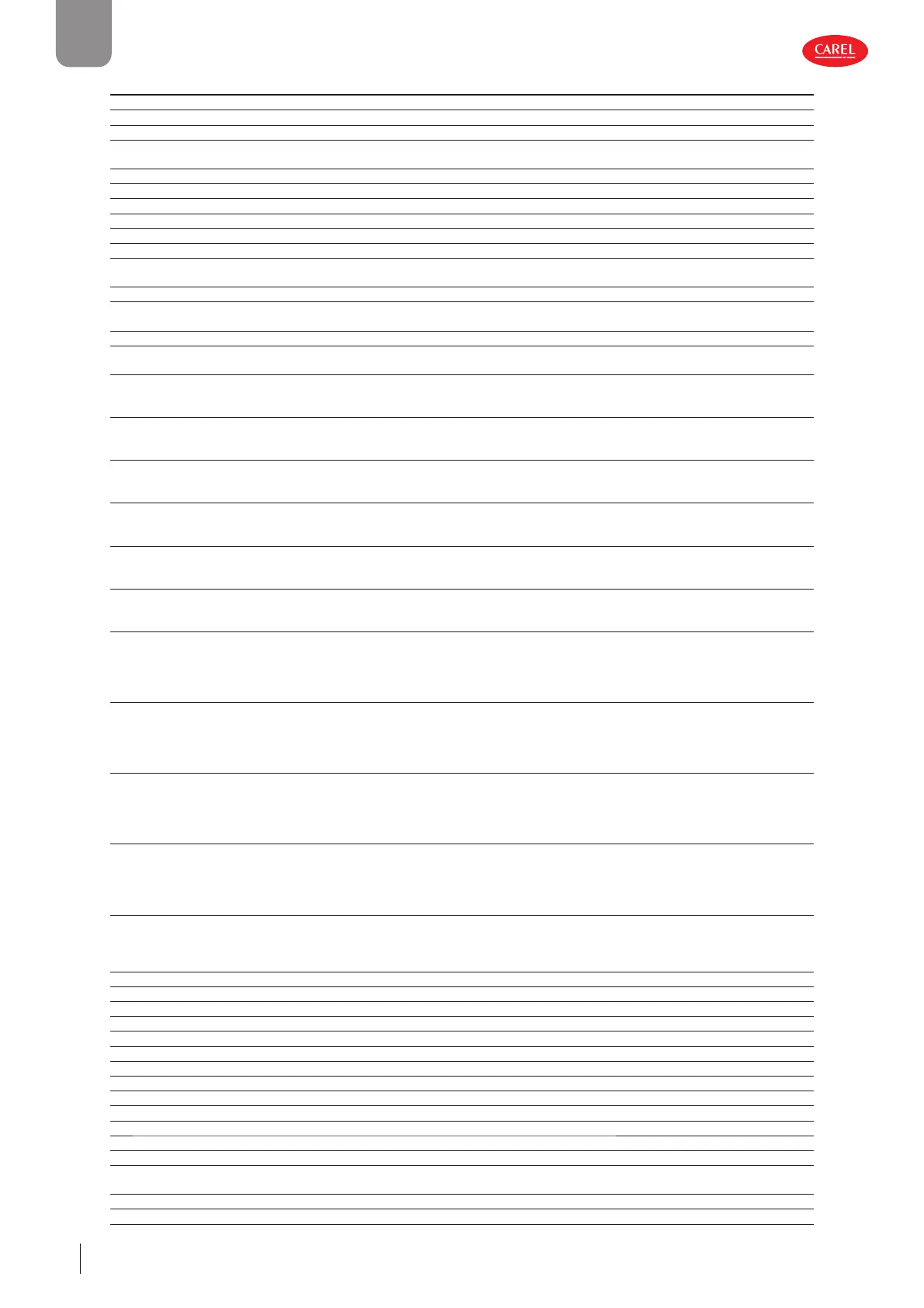

Supervisor table

Index Size Ref. Type Min/Max R/W UoM Description

265 1 S048 INT 0 to 999 R/W s S048 - Dripping duration

266 1 S049 INT 0 to 999 R/W s S049 - Post-dripping duration

267 1 S050 INT 0 to 999 R/W min S050 - Delay between defrosts

272 1 S053 INT 0..2 R/W S053 - Defrost synchronisation type

(0 = Independent, 1 = Separate, 2 = Simultaneous)

274 2 S054 REAL 0..999.9 R/W bar/psi S054 - Pressure diff erential to reverse 4-way valve

278 1 S056 INT 20 to 999 R/W s S056 - Smart start function duration

279 2 S057 REAL -999.9..999.9 R/W °C/°F S057 - Source frost protection alarm threshold

281 2 S058 REAL 0 to 999 R/W K/R S058 - Source frost protection alarm diff erential

283 1 S059 INT 0 to 999 R/W s S059 - Source frost protection alarm delay at 1K below the threshold

284 2 S060 REAL -99.9..99.9 R/W K/R S060 - Source outside air temperature off set

286 1 Hc00 INT 0..3/4 R/W Hc00 - Analogue input 3 confi guration (0 = not used, 1 = source temp., 2 = dis-

charge temp., 3 = suction temp., 4 = source delivery water temp.)

287 1 Hc01 INT 0..1 R/W Hc01 - Analogue input 4 and 5 confi guration (0 = pressure, 1 = temp.)

288 1 Hc03 INT 0..2 R/W Hc03 - Analogue input 6 confi guration (0 = not used, 1 = remote set point, 2 =

source temp.)

289 1 Hc04 INT 0..1 R/W Hc04 - Analogue input 7 confi guration (0 = not used, 1 = suction temp.)

290 1 Hc05 INT 0..1 R/W Hc05 - Analogue input 6 confi guration, circuit 2 board (0 = not used, 1 = remote

set point)

291 1 Hc06 INT 0..6 R/W Hc06 - Digital input 4 confi guration (0 = Not used, 1 = Comp. 2 circ. 1 overload, 2

= Remote ON/OFF, 3 = Cool/Heat, 4 = 2nd set point, 5 = Remote alarm, 6 = User

pump 1 overload)

292 1 Hc07 INT 0..6 R/W Hc07 - Digital input 5 confi guration (0 = Not used, 1 = Comp. 2 circ. 1 overload, 2

= Remote ON/OFF, 3 = Cool/Heat, 4 = 2nd set point, 5 = Remote alarm, 6 = User

pump 1 overload)

293 1 Hc08 INT 0..6 R/W Hc08 - Digital input 6 confi guration (0 = Not used, 1 = Comp. 2 circ. 1 overload, 2

= Remote ON/OFF, 3 = Cool/Heat, 4 = 2nd set point, 5 = Remote alarm, 6 = User

pump 1 overload)

294 1 Hc09 INT 0..5 R/W Hc09 - Digital input 4 confi guration, circuit 2 board (0 = Not used, 1 = Comp. 2

circ. 2 overload, 2 = Remote ON/OFF, 3 = Cool/Heat, 4 = 2nd set point, 5 = Remote

alarm, 6 = User pump 1 overload)

295 1 Hc10 INT 0..5 R/W Hc10 - Digital input 5 confi guration, circuit 2 board (0 = Not used, 1 = Comp. 2

circ. 2 overload, 2 = Remote ON/OFF, 3 = Cool/Heat, 4 = 2nd set point, 5 = Remote

alarm, 6 = User pump 1 overload)

296 1 Hc11 INT 0..5 R/W Hc11 - Digital input 6 confi guration, circuit 2 board (0 = Not used, 1 = Comp. 2

circ. 2 overload, 2 = Remote ON/OFF, 3 = Cool/Heat, 4 = 2nd set point, 5 = Remote

alarm, 6 = User pump 1 overload)

297 1 Hc14 USINT 0..ID_CfgLim-

Max

R/W Hc14 - Digital input 1 confi guration (0 = Not used, 1 = User fl ow switch, 2 = Comp.

1 circuit 1 overload, 3 = Comp. 2 circuit 1 overload, 4 = Remote ON/OFF, 5 = Cool/

Heat, 6 = 2nd set point, 7 = Remote alarm, 8 = User pump 1 overload, 9 = Low

pressure switch, 10 = User pump 2 overload, 11 = Remote control 1, 12 = Remote

control 2)

298 1 Hc15 USINT 0..ID_CfgLim-

Max

R/W Hc15 - Digital input 2 confi guration (0 = Not used, 1 = User fl ow switch, 2 = Comp.

1 circuit 1 overload, 3 = Comp. 2 circuit 1 overload, 4 = Remote ON/OFF, 5 = Cool/

Heat, 6 = 2nd set point, 7 = Remote alarm, 8 = User pump 1 overload, 9 = Low

pressure switch, 10 = User pump 2 overload, 11 = Remote control 1, 12 = Remote

control 2)

299 1 Hc16 USINT 0..ID_CfgLim-

Max_Slv

R/W Hc16 - Digital input 1 confi guration, circuit 2 board (0 = Not used, 1 = User fl ow

switch, 2 = Comp. 1 circuit 2 overload, 3 = Comp. 2 circuit 2 overload, 4 = Remote

ON/OFF, 5 = Cool/Heat, 6 = 2nd set point, 7 = Remote alarm, 8 = User pump 1

overload, 9 = Low pressure switch, 10 = User pump 2 overload, 11 = Remote

control 3, 12 = Remote control 4)

300 1 Hc17 USINT 0..ID_CfgLim-

Max_Slv

R/W Hc17 - Digital input confi guration, circuit 2 board (0 = Not used, 1 = User fl ow

switch, 2 = Comp. 1 circuit 2 overload, 3 = Comp. 2 circuit 2 overload, 4 = Remote

ON/OFF, 5 = Cool/Heat, 6 = 2nd set point, 7 = Remote alarm, 8 = User pump 1

overload, 9 = Low pressure switch, 10 = User pump 2 overload, 11 = Remote

control 3, 12 = Remote control 4)

301 1 AI_Cf-

gLim-

Max_

Grp2

USINT --- R/W Maximum limit probe group 2

307 2 SEtC REAL U006..U007 R/W °C/°F SEtC - Cooling set point

309 2 SEtH REAL U008..U009 R/W °C/°F SEtH - Heating set point

324 2 C017 REAL 0..999.9 R/W °C/°F C017- Maximum high pressure threshold (HP)

326 2 C018 REAL -99.9..99.9 R/W bar/psi C018 - Min low pressure threshold (LP)

328 1 E047 INT 0..2 R/W E047 - Type of ExV driver (0 = Disabled, 1 = EVD embedded, 2 = EVD EVO)

335 2 P000 REAL -999.9..999.9 R/W °C/°F P000 - Min evaporation temp. limit for custom envelope

337 2 P001 REAL -999.9..999.9 R/W °C/°F P001 - Max condensing temp. limit for custom envelope

339 1 P002 INT 0 to 999 R/W s P002 - Min. prevent duration

340 1 P003 INT 0 to 999 R/W s P003 - Out of envelope alarm delay time

341 1 P004 INT 0 to 999 R/W s P004 - Low pressure diff erential alarm delay

342 2 P005 REAL 0..999.9 R/W rps P005 - Min BLDC speed threshold for circuit destabilisation

344 2 P006 REAL 0..100 R/W % P006 - Oil recovery min request for activation

346 2 P007 REAL 0..999.9 R/W rps P007 - Oil recovery min comp. speed for activation

348 1 P008 INT 0 to 999 R/W min P008 - Oil recovery time before activation in which the compressor can operate at

minimum speed

349 1 P009 INT 0 to 999 R/W min P009 - Oil recovery duration to override comp. speed

350 2 P010 REAL 0..999.9 R/W rps P010 - Oil recovery comp. override speed

Loading...

Loading...