13

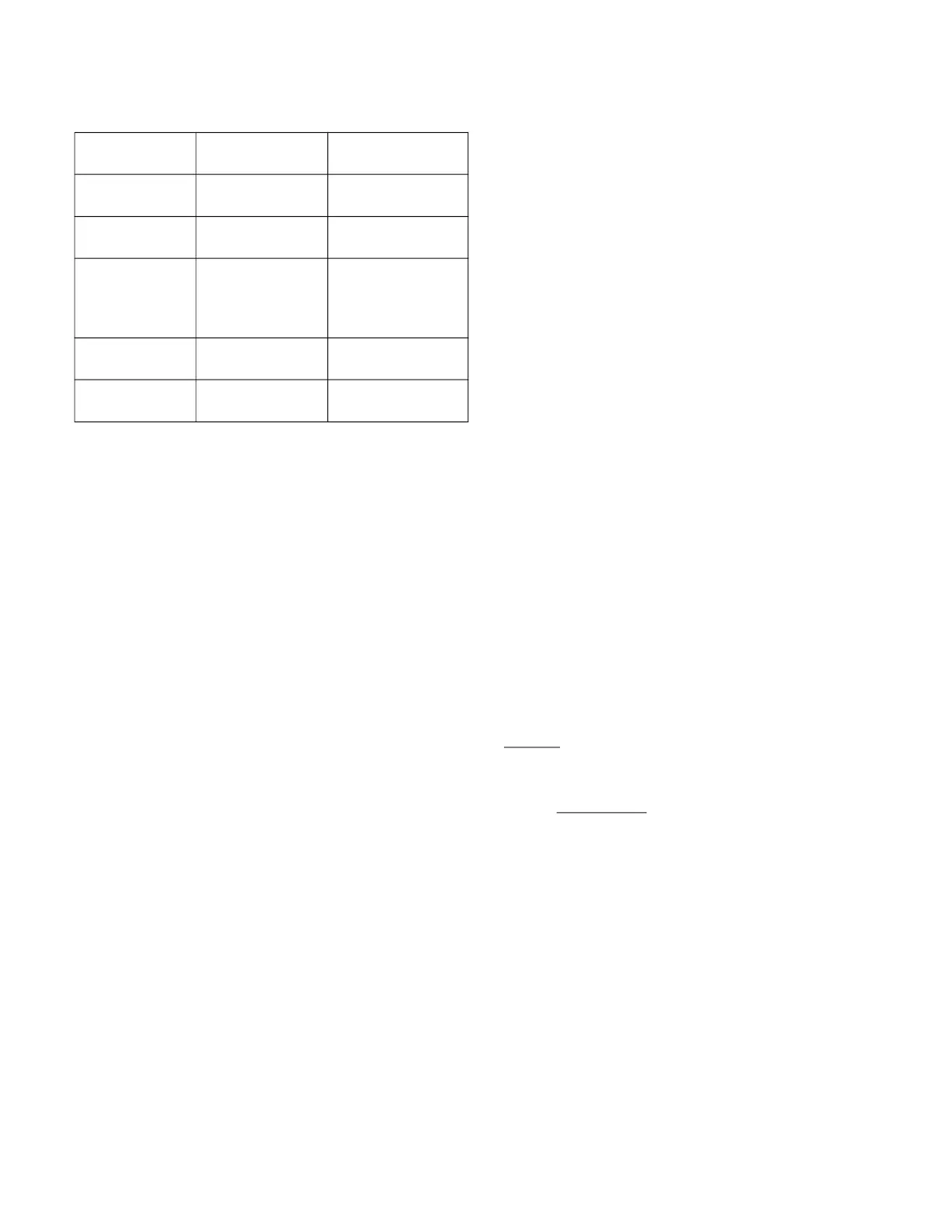

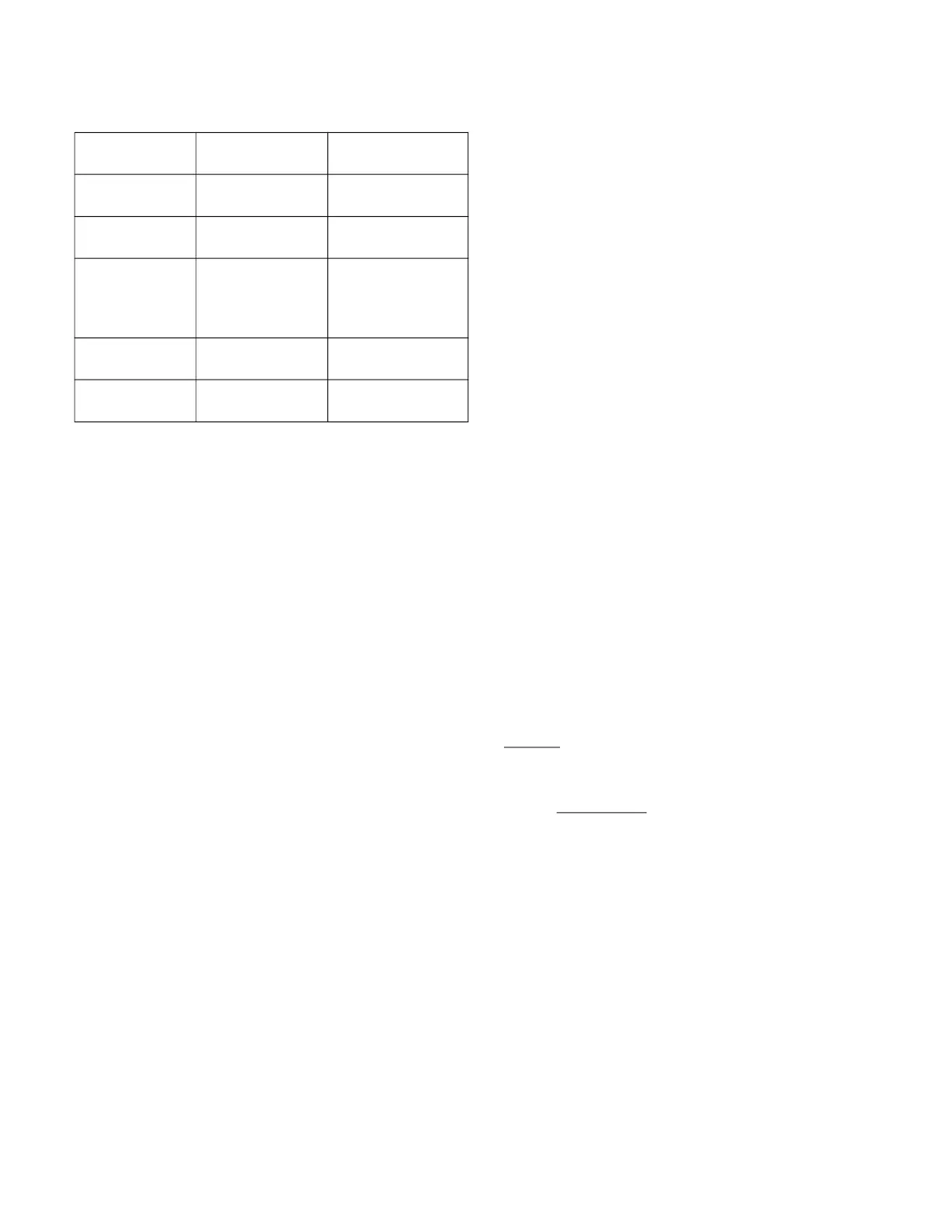

Table 5 — Allowable Temperature Ranges

Compressor Rotation Control

Correct compressor rotation is one of the most critical

application considerations. Powered reverse rotation,

even for a very short duration, can seriously affect the

reliability of the compressor.

The reverse rotation protection scheme must be

capable of determining the direction of rotation and

stopping the compressor within 1 second.

Reve

rse rotation is most likely to occur at initial start-up

or whenever the wiring to the compressor terminals is

disturbed.

To minimize the possibility for reverse rotation operation,

Carlyle recommends the following procedures:

1. During initial run test of the unit, a suitable low-

pressure switch should be temporarily installed on

the high-pressure port of the compressor and be

wired to open the comp

ressor control circuit. The

purpose of this switch is to protect the compressor

against any wiring errors at the compressor terminal

pins. The electrical contacts of the switch must be

wired in the control circuit of the compressor start

components to shut off the compressor in the event it

is operating in reverse rotation. This switch would

remain in place for the duration of the run test. At the

end of the run test the switch would be removed so

that it could be used on the next unit or compressor

to be tested.

2. For service replacement compressors, a similar pro-

tection system is recommended. The unit service lit-

erature will make reference to this switch and provide

instructions on how to temporarily install the low-

pressure switch into the safety circuit for the com-

pressor. Each serv

ice compressor will be supplied

with Installation Instructions documenting the proce-

dure for installing and using the switch. The switch

will remain in place until the compressor has been

started and direction of rotation has been verified; at

this point the switch will be removed.

The low-pressure switch must be suitable for the pres-

sures consistent with R-134a systems, and the switch

must be ma

nually resettable and open when the pressure

falls below 50 mm (2 inches) of vacuum. The switch is a

manual reset type that can be reset after the pressure

has once again risen above 1.7 bar (25 psia). It is critical

that the switch be a manual reset type to preclude the

compressor from short cycling in the reverse direction.

If a switch is not available, a manifold gage connected to

the discharge

housing of the compressor BEFORE THE

DISCHARGE CHECK VALVE can be used. If the com-

pressor can be “bumped” or “jogged” very quickly (< 1

second) while someone is watching the gage, compres-

sor rotation can be determined without damage to the

compressor. If the pressure drops, the compressor is

rotating backwards and will have to be rewired. If the

pressure goes up, the compressor is spinning in the cor-

rect direction.

Refrigeration System Design Cons iderations

In order to eliminate the possibility of refrigerant migrat-

ing into the oil separator and compressor, Carlyle

requires

the application of a positive-seal, discharge

check valve (or a similar functioning device) to be

installed in the discharge line after the oil separator.

Carlyle recommends

the application of our qualified

Safety Control Module package (P/N 6BSB000472)

which provides the following safety control functionality:

• Discharge Temperature Monitoring

• Oil Level Monitoring (Optional)

• Reverse Rotation Monitoring

• Oil Flow-Rate/Supply Monitoring

Technical documentation for this Safety Control Module

package (P/N 6BSB000472) is provided on the Carlyle

Website at www.carlylecompressor.com

CONTROL

POINT

MINIMUM MAXIMUM

Discharge

Gas

20°F (11°C)

superheat

210°F (99°C)

Economizer

Gas

Saturated

Liquid

9°F (5°C)

superheat

Suction

Gas

Saturated

Va

por

Can float if motor

and discharge

maximum temps

are met

Oil Supply at

Compressor

Refer to Fig. 8 210°F (99°C)

Motor

Windings

No limit 275°F (135°C)

Loading...

Loading...