28

5.2 Approximate Part Load Factors

Table 11 shows the typical relation of part load capacity

and power at their respective rating conditions. Contact

Carlyle Application Engineering for further information.

Table 11 — Typical Relation of Part Load Capacity

Certain fully unloaded operating conditions may result in

discharge gas temperatures which exceed the recom-

mended operating parameters. Carlyle requires

that

some form of liquid injection be applied to control/reduce

discharge gas temperatures to be within recommended

guidelines. Common methods to accomplish this may

include increased flow through the economizer circuit or

direct liquid injection into the economizer port/tubing.

5.3 Slide Valve Capacity Controller and Pro-

tection

5.3.1 General Description

The Carlyle Control Module (CCM) will function to control

compressor capacity by operating the compressor's slide

valve to maintain the system's control set point (suction

pressure or temperature). This process control point is an

input to the CCM. In addition, the CCM will have function-

ality to protect the compressor and provide LED fault sta-

tus indication for:

• Oil Level Protection

• Oil Flow Protection

• Motor Cooling Protection

• Discharge Temperature Protection

• Transducer Sensor Failure

• Temperature Thermistor Failure

The following Paragon capacity and protection kits

6BSB000929 and 6

BSB000930 are available through

Carlyle. See Table 12. Detailed information regarding the

Paragon Slide Valve controller may be found at www.car-

lylecompressor.com, Application Guide 575-012.

5.3.2 CCM Configuration

The CCM can be configured to function in the following 3

modes of operation:

1. Slide Valve Control and Compressor Protection

(Default Setting).

2. Slide Valve Control only.

3. Compressor Prot

ection only.

Configuring the CCM for options 2 or 3 can be accom-

plished through:

• Using the BACview

1

hand-held display unit.

• Downloading BACview software to a laptop.

• Setting up a communication port between the CCM

and System Controller.

To allow easier transmission of data across a network

between the CCM and the System Controller, the CCM is

pre-configured with the following protocol networks:

• BACnet

2

• Modbus

3

• N2 Open

• LonWorks

4

(requires optional card)

• RS485 Communication Port

Table 12 — Paragon Capacity and Protection Kits

% FULL

LOAD

CAPACITY

AIR-COOLED (R-134a) WATER-COOLED (R-134a)

% FULL LOAD POWER % FULL LOAD POWER

100 10

0 100

75 78 78

50 58 58

34 50 50

15 — 50

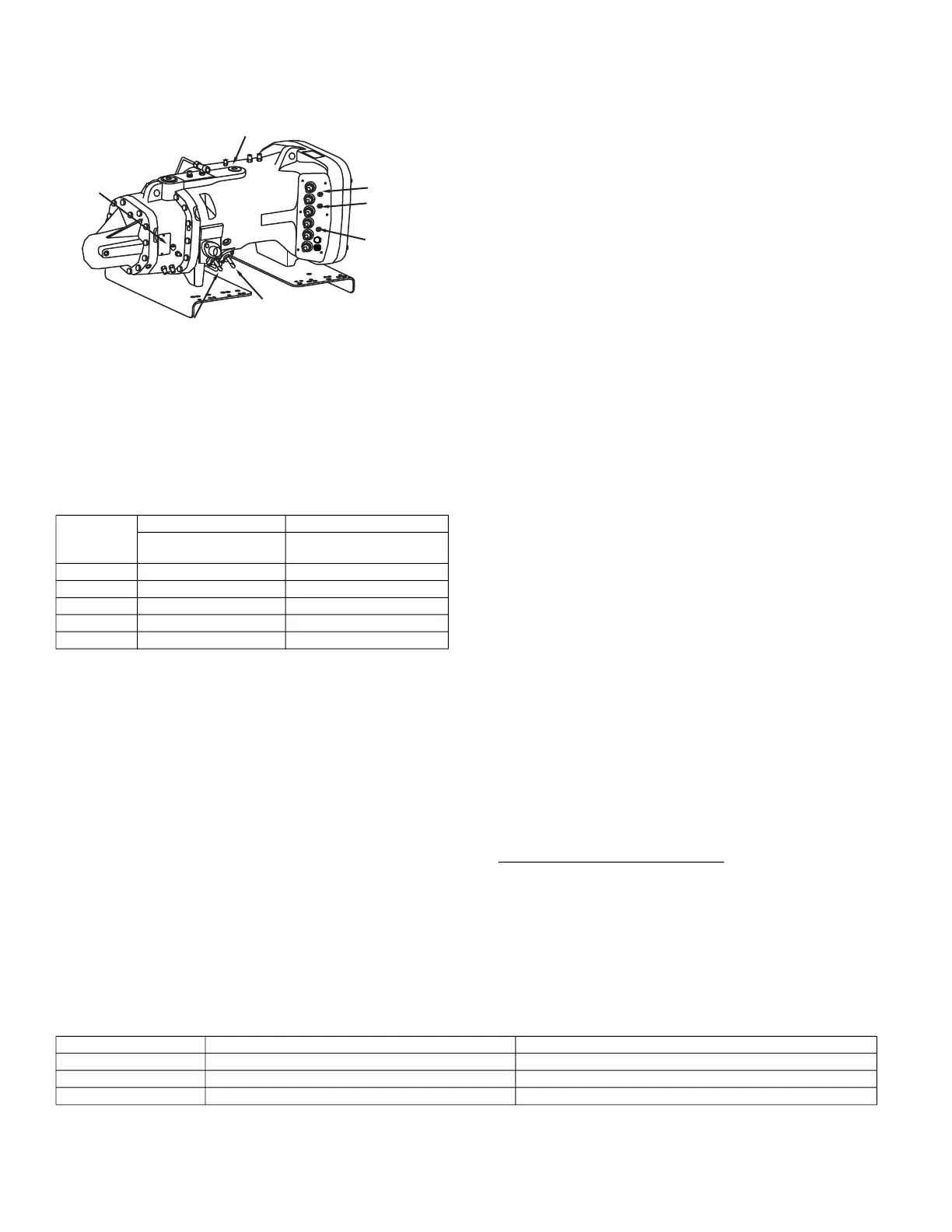

Fig. 22 — Solenoid Locations

SOLENOID 1

SOLENOID 2

HIGH PRESSURE

SWITCH

MOTOR

TEMPERATURE

SENSOR 2

COMMON

MOTOR

TEMPERATURE

SENSOR 1

SUCTION

TEMPERATURE

1. BACview is a registered trademark of Automated Logic

Corporation.

2. BACnet is a registered trademark of ASHRAE (American

Society of Heating, Refrigeration and Air-Conditioning

Engineers).

3. Modbus is a registered trademark of Schneider Electric.

4. LonWorks is a registered trademark of Echelon Corporation.

CARLYLE P/N DESCRIPTION APPLICATION

6BSB000929 High Temperature Paragon Controller Kit R-134a, R513A

, R1234ze

6BSB000930 Low/Medium Temperature Paragon Controller Kit R404A, R-407A, R-407C, R-407F, R-448A, R-449A, R-507A

USB-L CCM Interface Cable Cable interface between controller and laptop

Loading...

Loading...