27

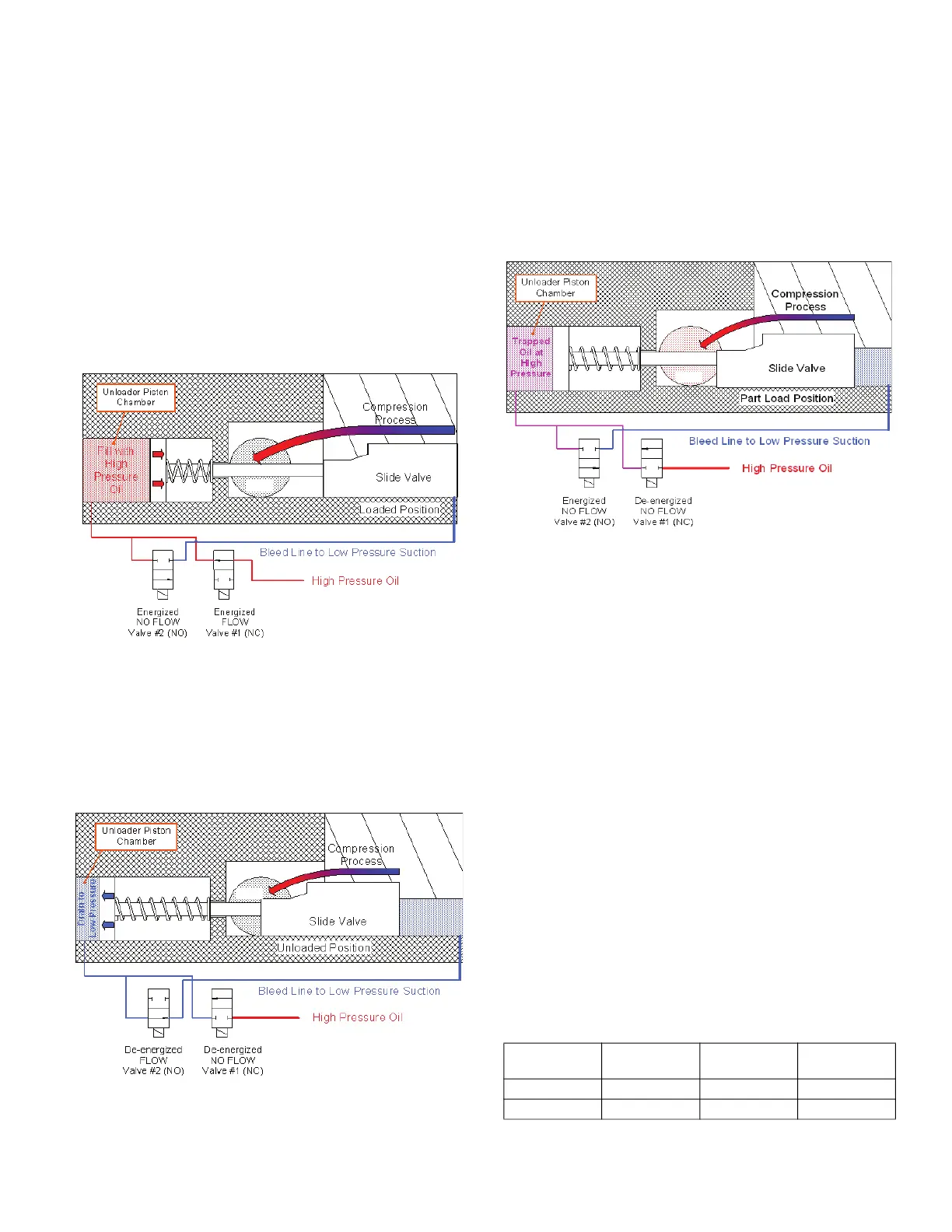

All Paragon compressors come equipped with an

infinitely adjustable slide valve unloading system. The

actual capacity reduction will depend on the system oper-

ating conditions and the rebalance characteristics.

Two solenoids control the slide valve by allowing commu-

nication between the unloader piston chamber and either

high pressure oil or low pressure suction.

• To fully load the compressor, bot

h solenoid #1 and #2

are energized (see Fig. 19). This allows high-pressure

oil to enter the unloader piston chamber, moving the

slide valve and providing more engagement under the

screw rotors. Both solenoids should remain energized

to maintain the full load position.

• To unload the compressor, both solenoids are de-

energized (Fig. 20). This exposes the unloader piston

chamber to suction pressure, pulli

ng the slide valve

out from under the screw rotors and reducing the

amount of compression being performed.

.

• Part load is achieved by stopping the load or unload

process previously described at an intermediate slide

valve position. Stopping the valve at an intermediate

position is accomplished by de-energizing valve #1

and energizing valve #2 (Fig. 21). When this happens,

both valves are closed and the pi

ston is not allowed to

move. Cycling of the solenoids may be required to

compensate for leakages around the piston seal, etc.

The TU and TV water-cooled models have a hot gas

bypass port on the slide valve. This feature allows dis-

charge gas to leak back to suction through the slide valve

when the slide valve is in the fully unloaded position. The

hole is closed at all other load states. The purpose

of this

feature is to allow the compressor to unload to 15% of the

full load capacity.

The compressor will start with minimum power draw in

the fully unloaded state. There is no minimum or maxi-

mum time limit immediately after start-up for which the

compressor must operate in the unloaded state. How-

ever, it is recommended that the compressor operates

unloaded for a minimum load for 30 seconds ju

st prior to

shutdown. This will ensure the compressor is fully

unloaded on the subsequent start, and means that the

compressor is drawing the minimum current when the

contactors open to shut down the compressor.

5.1 Unloader System Control Points

Table 10 shows the proper control states for the slide

valve solenoids. See Fig. 22 for solenoid locations.

Table 10 — Proper Control States for

Slide Valve Solenoid

s

* Maintain capacity: Solenoid activation after proper slide valve position

has been attained.

Fig. 19 — Fully Loaded Operation

Fill with

High

Pressure

Oil

DISCHARGE

PORT

Fig. 20 — Configuration for Unloading

DISCHARGE

PORT

Drain to

Low Pressure

INCREASE

CAPACITY

DECREASE

CAPACITY

PARTIAL*

SOLENOID #1 Energized De-Energized De-Energized

SOLENOID #2 Energized De-Energized Energized

Fig. 21 — Configuration for Maintaining Part Load

DISCHARGE

PORT

5.0 Unloader Operation

Loading...

Loading...