15

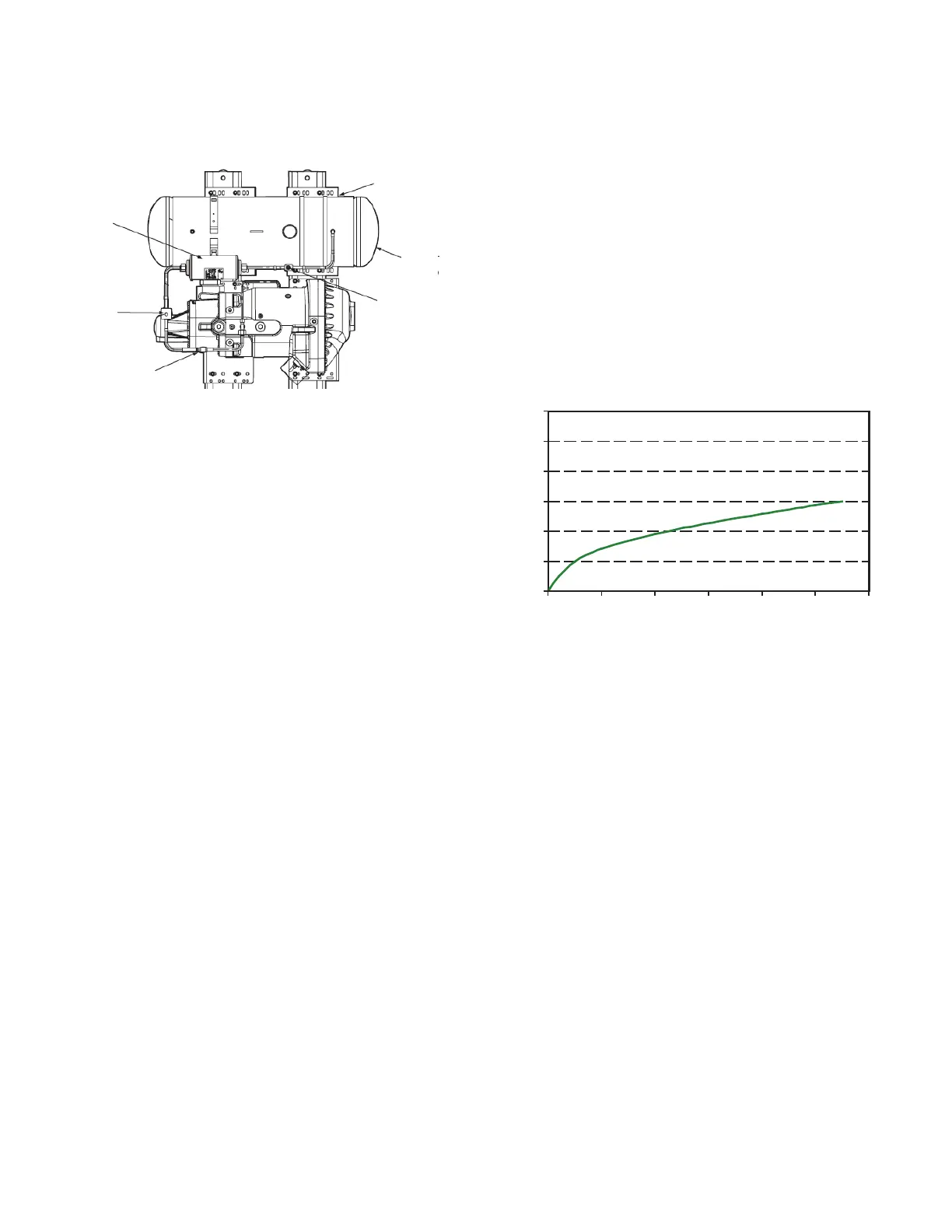

Oil supply system components are shown in Fig. 9.

2.1 Oil Pressure Requirements

System pressure is used to generate the oil pressure

required to lubricate bearings and provide the oil that

acts as a seal between the screw rotors and the bores.

Oil pressure is monitored continuously during compres-

sor operation. The oil pressure must meet the following

criteria, based on P

DISCHARGE

, P

SUCTION

and

P

OIL

:

1. P

OIL

> [0.7 x (P

DISCHARGE

– P

SUCTION

) + P

SUCTION

]

2. P

OIL

> [P

SUCTION

+ 0.5 bar] 15 seconds after start

[P

SUCTION

+ 1.0 bar] 45 seconds after start

(Air-Cooled models; A in fifth digit of model number)

[P

SUCTION

+ 1.0 bar] 75 seconds after start

(Water-cooled models; W in 5th digit of model number)

The unit control system must monitor the oil pressure dif-

ferential, as well as the operating con

dition, so the com-

pressor can be shut down if the minimum requirements

are not met for any duration exceeding 15 seconds.

This time delay has two functions: first, to avoid nuisance

tripping during normal and transient operation, and sec-

ond, to allow the system sufficient time to develop pres-

sure differential during start-up.

The compressor must be shut down and prevented from

restarting when the

low oil pressure safety is tripped. The

safety should be a manual reset type that locks out com-

pressor operation until the system is serviced.

Carlyle offers a Compressor Protection Module package

to provide protection against loss of oil flow, reverse-rota-

tion and elevated discharge gas temperature.

2.2 Oil Separator Recommendations

The Paragon compressor requires an oil separator. The

combined oil capacity of the oil separator sump, the oil

reservoir, and the oil cooler, should be greater than the

values shown in Table 6.

The separator should be selected to provide a maximum

oil carryover leaving the separator required by that sys-

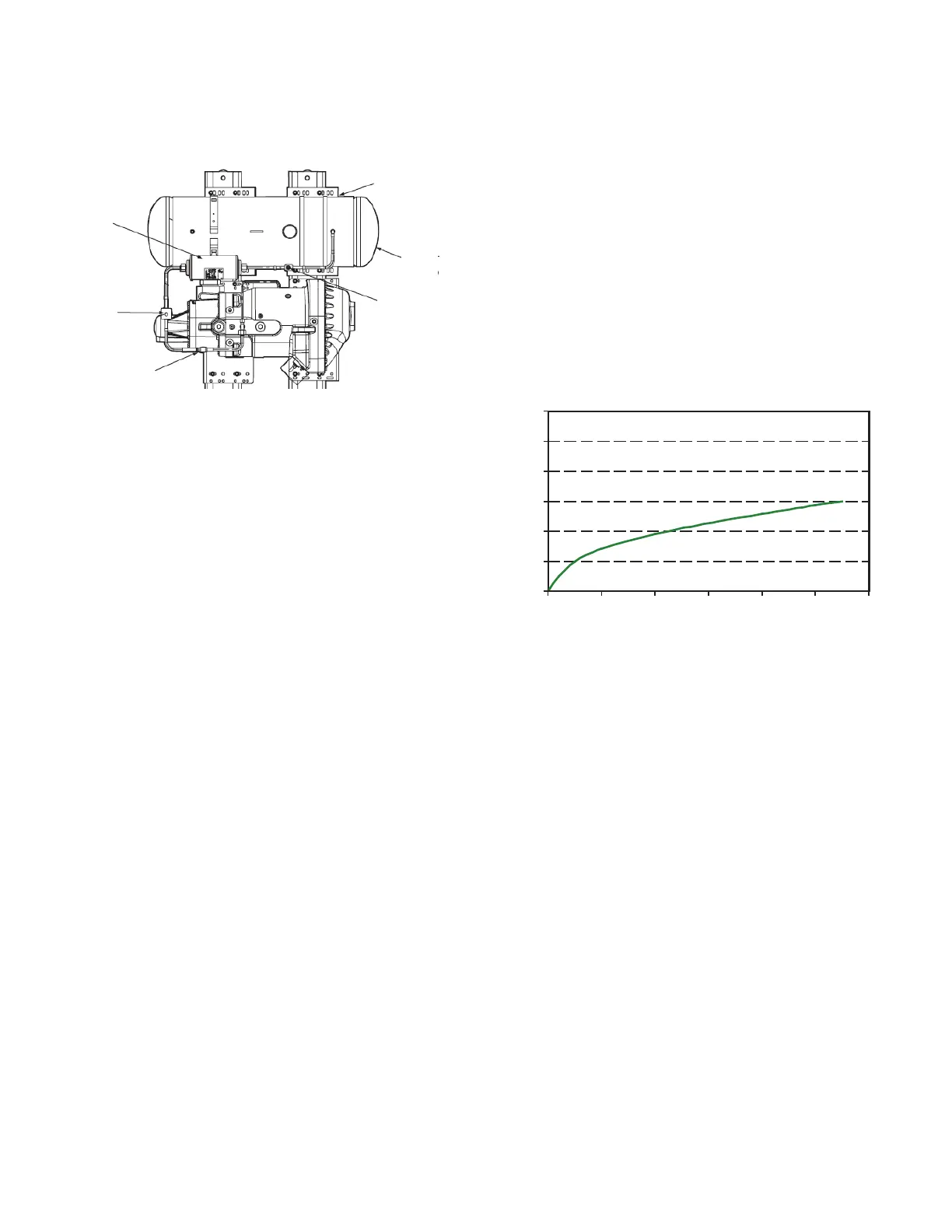

tem/application. Approximate oil flow versus compressor

pressure differential (Discharge Pressure - Suction Pres-

sure) is shown in Fig. 10. Additional oil ch

arge may be

required for systems that have longer tubing sets. See

Sections 9.1.1, 9.1.2, and 10.5 for additional information.

2.3 Oil Heater Recommendations for

Air-Cooled Models

For the typical oil separators used with the Paragon com-

pressor (see Table 6), a 500-watt flexible strip heater is

recommended. The heater should be wired to operate

when the compressor is OFF. This minimizes the migra-

ti

on of refrigerant to the oil stored in the sump. Figure 8

shows the minimum oil temperatures that must be main-

tained when the compressor is not operating based on

the outdoor ambient temperature (OAT). If the application

will allow refrigerant to collect in the compressor, then a

heater must be installed on the compressor. Running unit

water that is at least 20°F (11°C) below OAT, if possible,

can be used to prevent refrigerant from collecting in the

co

mpressor. Carlyle recommends that the oil tempera-

ture be monitored in warm climate applications and that

the oil separator heater be cycled off if oil temperatures

reach 190°F (88°C).

OIL

FILTER

OIL

SOLENOID

VALVE

CHECK

VALVE

OIL

SEPARATOR

HEATER

(BOTTOM)

OIL

LEVEL

SWITCH

(BOTTOM)

OIL

SHUTOFF

VALVE

Fig. 9 — Oil Supply System Components

a06-1685

Fig. 10 — Oil Supply at Compressor

0

1

2

3

4

5

6

0 50 100 150 200 250 300

Discharge - Sucon Pressure (PSID)

Typical Oil Flow Rate (GPM)

LEGEND

A/C — Air-Cooled

W/C — Water-Cooled

2.0 Medium/High Temperature System Oil Management

(R-134a, R-513A, R-1234ze)

Loading...

Loading...