32

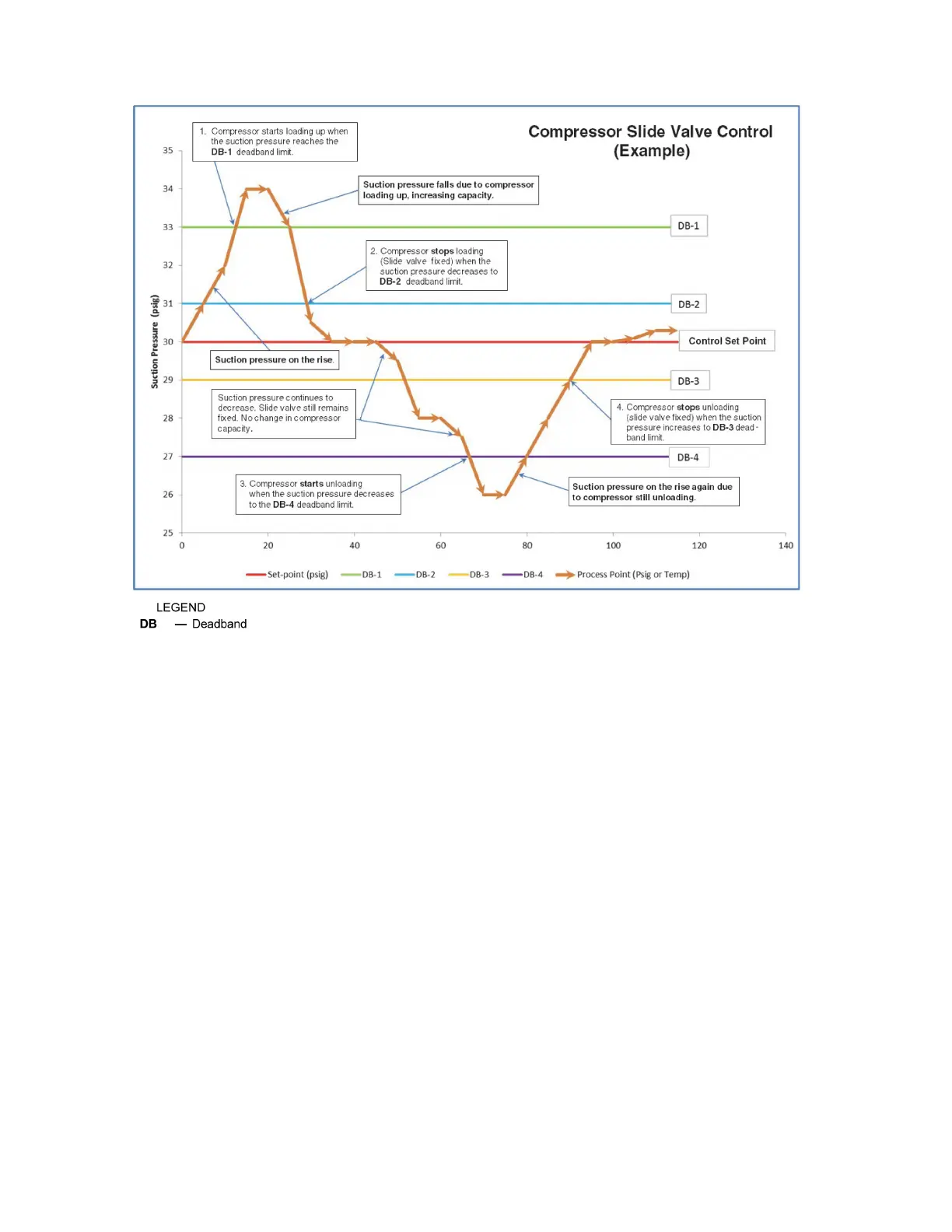

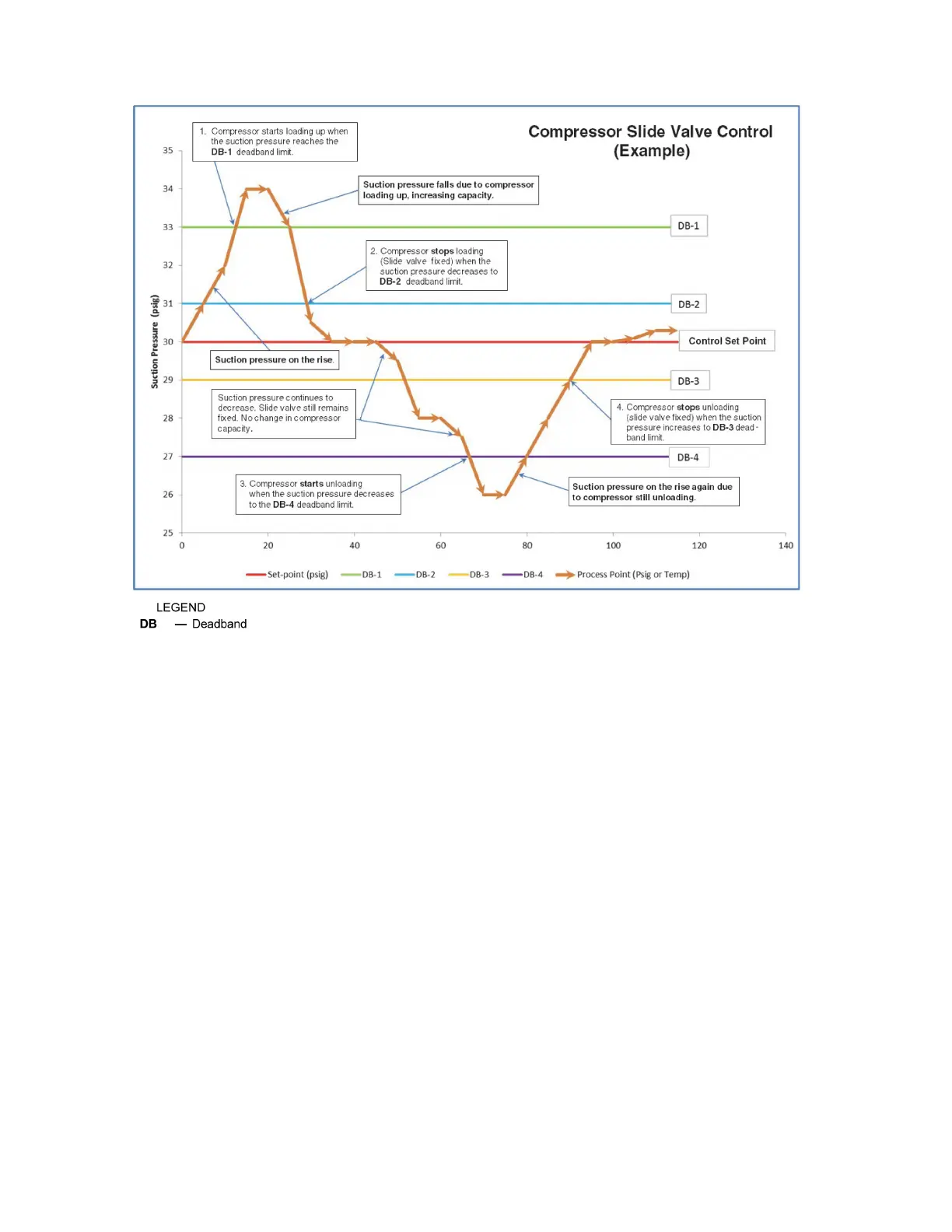

Fig. 27 — Paragon Slide Valve Control Illustration

5.3.5 Compressor Protection

Motor and discharge temperature control for a screw

compressor is critical. Excessive motor and discharge

gas temperatures can cause premature compressor fail-

ure; therefore, control of these temperatures is very

important. The CCM monitors these temperatures

through the use of the factory-installed 5K thermistor in

the motor w

indings and a field-installed 5K thermistor in

the compressor discharge temperature thermo-well.

When the thermistors indicate an overheated condition,

the CCM will perform the following:

• Energize a liquid injection valve, sending cool liquid

into the motor compartment.

• Override the Slide Valve and restrict the compressor

from unloading and or force the compressor to fully

load to reduce motor and or discharge temperature.

• Trip the compressor off.

Motor Temperature (Tm) will have the following functions:

• Control a motor cooling valve to provide liquid injec-

tion to the motor compartment.

• Override the compressor slide valve to reduce motor

temperature.

• Turn the compressor off on an overheated motor

temperature condition.

• See Table 13: Motor and Discharge Temperature

Control Points and Table 14: Slide Valve Override

Control Points for Tm control points.

Motor Temperature (Td) will have the following functions:

• Override the compressor slide valve to reduce dis-

charge temperature.

• Turn the compressor off on a high discharge tem-

perature condition.

• See Table 13: Motor and Discharge Temperature

Control Points and Table 14: Slide Valve Override

Control Points for Td control points.

5.3.6 LED Fault Indication

The CCM will provide an LED ala

rm output signal to the

System Controller when a compressor fault condition

arises. See Tables 15 and 16.

Loading...

Loading...