The air handling capacity of this furnace is designed for cooling

airflow. Refer to Table 13 or 14 for expected airflows at various

external duct static pressures.

LOCATION

Step 1—General

ELECTRICAL SHOCK, FIRE OR UNIT DAMAGE

HAZARD

Failure to follow this warning could result in property damage

or personal injury or death.

This furnace is not water tight and is not designed for outdoor

installation. This furnace shall be installed in such a manner

as to protect electrical components from water. Outdoor

installation would lead to a hazardous electrical condition and

to premature furnace failure.

UNIT DAMAGE HAZARD

This oil furnace may be used for construction heat provided

that:

-The furnace operating conditions, including ignition, input

rate, temperature rise and venting, are verified per instruc-

tions in this manual

-The furnace is permanently installed with all electrical

wiring, piping, venting and ducting installed according to

these installation instructions. A return air duct is provided,

sealed to the furnace casing, and terminated outside the space

containing the furnace. This prevents a negative pressure

condition as created by the circulating air blower, causing a

flame rollout and/or drawing combustion products into the

structure.

-The furnace is controlled by a thermostat. It may not be ″hot

wired″ to provide heat continuously to the structure without

thermostatic control.

-Clean outside air is provided for combustion. This is to

minimize the corrosive effects of adhesives, sealers and other

construction materials. It also prevents the entrainment of

drywall dust into combustion air, which can cause fouling and

plugging of furnace components.

-The temperature of the return air to the furnace is no less

than 55°F, with no evening setback or shutdown. The use of

the furnace while the structure is under construction is

deemed to be intermittent operation per our installation

instructions.

-The air temperature rise is within the rated rise range on the

furnace rating plate, and the firing rate has been set to the

nameplate value.

-The filters used to clean the circulating air during the

construction process must be either changed or thoroughly

cleaned prior to occupancy.

-The furnace, ductwork and filters are cleaned as necessary to

remove drywall dust and construction debris from all HVAC

system components after construction is completed.

FIRE HAZARD

Failure to follow this caution may result in property damage.

For attic installation, it is important to keep insulation 12 in.

or more away from any furnace openings. Some types of

insulating materials may be combustibles.

This furnace is approved for reduced clearances to combustible

construction, therefore, it may be installed in a closet or similar

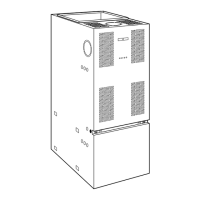

enclosure. Since this unit may be installed in an upflow, downflow,

or horizontal position, it may be located in a basement or on the

same level as area to be heated. In any case, unit should always be

installed level.

In a basement, or when installed on floor (as in a crawlspace), it is

recommended that unit be installed on a concrete pad that is 1 in.

to 2 in. thick.

When installed in downflow position, furnace must not be installed

on combustible flooring, unless approved subbase is used. Also,

since flue pipe is in a downflow position, Downflow

Conversion/Vent Guard Kit MUST be used.

When installed in a horizontal position, furnace may be suspended

by using an angle iron frame, as long as total weight of both

furnace and frame are allowed for in support calculations. (Other

methods of suspending are acceptable.) When installed in the

Horizontal Position, this furnace must not be installed on combus-

tible flooring, unless the approved Horizontal Subbase is used.

The required minimum clearances for furnace are specified in

Table 1.

The furnace should be located as close as possible to chimney or

vent in order to keep vent connections short and direct. The

furnace should also be located as near as possible to center of air

distribution system.

Step 2—Location Relative to Cooling Equipment

When installing furnace with cooling equipment for year-round

operation, the following recommendations must be followed for

series or parallel airflow:

1. In series airflow applications, coil is mounted after furnace in

an enclosure in supply-air stream. The furnace blower is used

for both heating and cooling airflow.

UNIT DAMAGE HAZARD

The coil MUST be installed on air discharge side of furnace.

Under no circumstances should airflow be such that cooled,

conditioned air can pass over furnace heat exchanger. This

will cause condensation in heat exchanger and possible

failure of heat exchanger which could lead to a fire hazard

and/or a hazardous condition which may lead to bodily harm.

Heat exchanger failure due to improper installation may not

be covered by warranty.

2. In parallel airflow applications, dampers must be provided to

direct air over furnace heat exchanger when heat is desired and

over cooling coil when cooling is desired.

IMPORTANT: The dampers should be adequate to prevent cooled

air from entering furnace. If manually operated, dampers must be

equipped with a means to prevent operation of either cooling unit

or furnace unless damper is in full cool or heat position.

3

Loading...

Loading...