5-3

5-2-3. Refrigerant blow down

During a cooling operation, a little quantity of absorbent could mix into the refrigerant. Accumulated

amount of the mixed absorbent could increase by a long-term operation and result in lowering of the

cooling capacity, therefore refrigerant blow down must be performed at least once in a cooling season.

By this work, the contaminated refrigerant is transferred to absorber side, and new, clear refrigerant is

replaced.

(1) Make sure the refrigerant pump is operating, and also the refrigerant level is visible through the

sight glass of the evaporator.

(2) Open the blow valve completely.

(3) When the solution level becomes invisible, close the blow valve tightly.

The above is the blow down procedure.

Repeat it a few times as necessary.

As for the refrigerant blow down, please make a maintenance contract with the service agent.

5-2-4. Management of the Absorbent solution

(1) Inspection and quality control of the absorbent solution

Lithium bromide (LiBr) solution is used as absorbent in the absorption chiller system. As it has

similar in nature to salt, the solution is corrosive therefore anticorrosive is added.

Concentration of the anticorrosive shall be checked periodically because it will be consumed with

operating hours, and therefore the concentration shall be controlled to keep the optimum level.

This follow-up management is seriously important to prevent a metal corrosion inside the unit and

thereby to ensure the long-life operation.

As for the management of the absorbent solution, make a maintenance contract with the service

agent.

(2) Regeneration of the absorbent solution

Even if absorbent is managed periodically, contamination and impurity will increase after a long

time operating.

In this case, consult to our service agent.

5-3. WATER TREATMENT

5-3-1. Water treatment for Chilled water and Cooling water

1. Importance of water treatment

Absorption chiller use copper tubes to prevent corrosion due to the use of fresh water (tube

material : JIS H 3300 C1201TS). However there is a possibility of corrosion due to water pollution or

poor water quality.

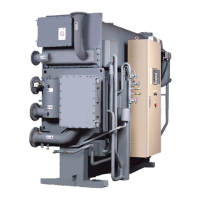

Refrigerant blow valve

Loading...

Loading...