6−2T-364

6.3 SERVICE CONNECTIONS

The compressor suction, compressor discharge, and

the liquid line service valves (see Figure 6−3) are pro-

vided with a double seat and an access valve which en-

ables servicing of the compressor and refrigerant lines.

Turning the valve stem clockwise (all the way forward)

will frontseat the valve to close off the line connection

and open a path to the access valve. Turning the stem

counterclockwise (all the way out) will backseat the

valve to open the line connection and close off the path

to the access valve.

With the valve stem midway between frontseat and

backseat, both of the service valve connections are

open to the access valve path.

For example, the valve stem is first fully backseated

when connecting a manifold gauge to measure

pressure. Then, the valve is opened 1/4 to 1/2 turn to

measure the pressure.

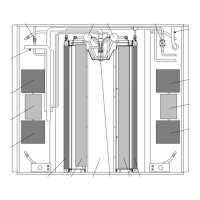

1

2

3

4

5

6

7

1. Line Connection

2. Access Valve

3. Stem Cap

4. Valve stem

5. Compressor Or Filter

Drier Inlet Connection

6. Valve (Frontseated)

7. Valve (Backseated)

Figure 6−3 Service Valve

Connection of the manifold gauge/hose set (see

Figure 6−4) is dependent on the component being

serviced. If only the compressor is being serviced, the

high side coupling is connected to the discharge service

valve.

For service of the low side (after pump down), the high

side coupling is connected to the liquid line service

valve. The center hose connection is brought to the tool

being used (vacuum, tank, etc.).

Connecting the manifold gauge set:

a. Remove service valve stem cap and to make sure the

valve is backseated.

b. Remove access valve cap (See Figure 6−3).

c. Connect the field service coupling (see Figure 6−2) to

the access valve.

d. Turn the field service coupling knob clockwise, which

will open the system to the gauge set.

e. To read system pressures, slightly midseat the ser-

vice valve.

f. Repeat the procedure to connect the other side of the

gauge set.

CAUTION

To prevent trapping liquid refrigerant in the

manifold gauge set be sure set is brought to

suction pressure before disconnecting.

Removing the Manifold Gauge Set:

a. While the compressor is still ON, backseat the high

side service valve.

b. Midseat both hand valves on the manifold gauge set

and allow the pressure in the manifold gauge set to be

drawn down to low side pressure. This returns any liq-

uid that may be in the high side hose to the system.

c. Backseat the low side service valve. Backseat both

field service couplings and frontseat both manifold

hand valves. Remove couplings from access valves.

d. Install both service valve stem caps and service port

caps (finger-tight only).

6.4 PUMP DOWN THE UNIT

To service the filter drier, economizer, expansion valves,

economizer solenoid valve, digital unloader valve or

evaporator coil, pump the refrigerant into the high side

as follows:

CAUTION

The scroll compressor achieves low suc-

tion pressure very quickly. Do not use the

compressor to evacuate the system below

0 psig. Never operate the compressor with

the suction or discharge service valves

closed (frontseated). Internal damage will

result from operating the compressor in a

deep vacuum.

a. Attach manifold gauge set to the compressor suction

and discharge service valves. Refer to paragraph 6.2.

b. Start the unit and run in the frozen mode (controller

set below -10C (14F) for 10 to 15 minutes.

c. Check function code Cd21 (refer to paragraph 3.2.2).

The economizer solenoid valve should be open. If

not, continue to run until the valve opens.

d. Frontseat the liquid line service valve. Place Start-

Stop switch in the OFF position when the suction

reaches a positive pressure of 0.1 bar (1.4 psig).

e. Frontseat the suction and discharge service valves.

The refrigerant will be trapped between the compres-

sor discharge service valves and the liquid line valve.

f. Before opening up any part of the system, a slight

positive pressure should be indicated on the pressure

gauge. Remove power from the unit before opening

any part of the system. If a vacuum is indicated, emit

refrigerant by cracking the liquid line valve momen-

tarily to build up a slight positive pressure.

g. When opening up the refrigerant system, certain

parts may frost. Allow the part to warm to ambient

temperature before dismantling. This avoids internal

condensation which puts moisture in the system.

Loading...

Loading...