6−5

T-364

6.8 COMPRESSOR

WARNING

Make sure power to the unit is OFF and power plug

disconnected before replacing the compressor.

WARNING

CAUTION

6.8.1 Removal and Replacement of Compressor

a. Turn the unit ON and run it in full cool mode for 10

minutes.

NOTE

If the compressor is not operational, front-seat

the suction and discharge service valves and

go to step e. below.

b. Frontseat the manual liquid li ne valve and allow the

unit to pull−down to 0.1 kg/cm

2

(1 psig).

c. Turn the unit start −stop switch (ST) and unit circuit

breaker (CB −1) OFF, and disconnect power to the

unit.

d. Frontseat the discharge and suction service valves.

e. Remove all remaining refrigerant from the com-

pressor using a refrigerant recovery system.

f. Remove the compressor terminal cover, disconnect

the ground wire and pull the cable plug from the com-

pressor terminals. Install the terminal cover back

after removing the power cable.

NOTE

Inspect the power cable (plug) terminals to en-

sure they are not deformed or have any signs of

heat or arcing. If any damage is noted, replace

the power cable.

g. Remove the Rotalock ttings from the suction and

discharge service connections, and uncouple the

unloader and economizer lines from the com-

pressor.

h. Cut the dome temperature sensor (CPDS) wires.

The replacement compressor comes with a CPDS

already assembled.

i. Remove and save the compressor base mounting

bolts. Discard the 4 top resilient mounts and wash-

ers.

j. Remove (slide out) the old compressor from the unit.

k. Inspect compressor base plate for wear. Replace, if

necessary.

l. Wire tie the compressor base

plate to the com-

pressor, and slide the new compressor into the unit.

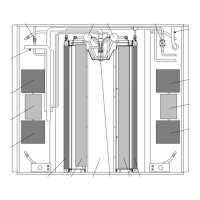

Refer to Figure 6 −5.

1

3

4

2

10

9

8

7

11

12

7

6

2

5

1. Compressor

2. Teon Seal for Valve

Connection (2)

3. O −Ring (Unloader

Connection)

4. Compressor Dis −

charge Temperature

Sensor

5. O −Ring (Economizer

Connection)

6. Base Mounting Bolts

7. SST Washers

8. Resilient Mount

9. Mylar Washers

10. Wire Ties

11. Power Cable Gasket

12. Ground Connection

Screw

13. Power Cable

Lubricant − Krytox

(Not Shown)

Figure 6 −5 Compressor Kit

NOTE

DO NOT add any oil to the replacement com-

pressor. Replacement compressor is shipped

with full oil charge of 60 oz.

m. Cut and discard the wire ties used to hold the base

plate to the compressor.

n. Place the new SST washers on each side of the resi-

lient mounts, and the new Mylar washer on the bot-

tom of it as shown in Figure 6 −5. Install the four base

mounting bolts loosely.

CAUTION

The PrimeLINE unit has a hermetically sealed

compressor that should not be opened and/or

repaired. Doing so can cause a loss in performance

and premature system failure due to the precision

machinery and assembly required within the

compresor. To repair the unit, remove the faulty

compressor and replace with an approved Carrier

compressor. If the return of the compressor is not

required, follow local waste collection and recycling

regulations in discarding the compressor.

The scroll compressor achieves low suction pressure

very quickly. Do not use the compressor to evacuate

the system below 0 psig. Never operate the compr-

essor with the suction or discharge service valves

closed (frontseated). Internal damage will result

from operating the compressor in a deep vacuum.

Before disassembly of the compressor, be sure to

relieve the internal pressure very carefully by

slightly loosening the couplings to break the seal.

Loading...

Loading...