% Building load

Reset value

8 - STANDARD CONTROL OPERATIONS AND OPTIONS

8.4.2 - Reset

Reset means that the active control point is modied so that the

machine capacity required is adjusted to be as close as possible

to the demand.

The reset source can be provided by one of the following:

■ Outdoor air temperature that gives a measure of the load

trends for the building. This reset source is applicable only to

units with option 154 (see section 8.15).

■ Return water temperature (heat exchanger ΔT gives an

average building load). Delta T (ΔT) is the difference between

leaving and entering uid temperatures (LWT minus EWT).

When the load is light, temperature difference across the

exchanger will be relatively small. The reset value should be

configured by the user and its configuration may differ

depending on the size of the water exchanger.

■ 4-20 mA reset signal provided by an active sensor connected

to the input: If the reading of the 4-20 mA signal/external

temperature value increases (load is lighter), then the current

setpoint will be lowered.

■ Space temperature reset based on the space temperature

sensor reading.

The source of the reset can be congured in the Reset Conguration

menu (RESETCFG). In response to a change in delta T, 4-20 mA

reset signal reading, or space temperature, the control point is

reset to optimise unit performance.

To set the source of the reset

1. Navigate to the Conguration menu.

2. Select Reset Conguration (RESETCFG).

3. Set Cooling Reset Select [cr_sel] or Heating Reset Select

[hr_sel].

Cooling Reset Select [cr_sel]

Heating Reset Select [hr_sel]

0 = none

1 = OAT *

2 = delta T

3 = 4-20 mA

4 = Space Temp

* OAT reset applies to units with option 154 (see section 8.15).

The unit normally uses two control point reset types, cooling control

point reset or heating control point reset.

Dry cooler condenser option has condensing setpoint reset which

can be applied if the condensing setpoint control depends on

outdoor air temperature reading (reset source = OAT). See also

section 8.15.

Reset is a linear interpolation function based on the following

three parameters:

■ A reference at which reset is zero (OAT / delta T / 4-20 mA

signal / space temp. – no reset value).

■ A reference at which reset is maximum (OAT / delta T / 4-20 mA

signal / space temp. – full reset value).

■ The maximum possible reset value: The difference between

the lowest reset value (no reset value) and the highest possible

reset value (full reset value). Cooling / Heating Reset Deg.

Value represents the maximum possible reset.

Reset parameters, i.e. slope, reset, and maximum value, are

congurable in the Reset Conguration menu (RESETCFG).

Cooling mode: Cooling control point reset is used to control the

evaporator water temperature reset.

Heating mode: Heating control point reset is used to control the

condenser water temperature reset.

Heating reset may be used to reset the condensing setpoint for

optimised condenser operation. This is only possible on the outside

temperature. Delta T is not used.

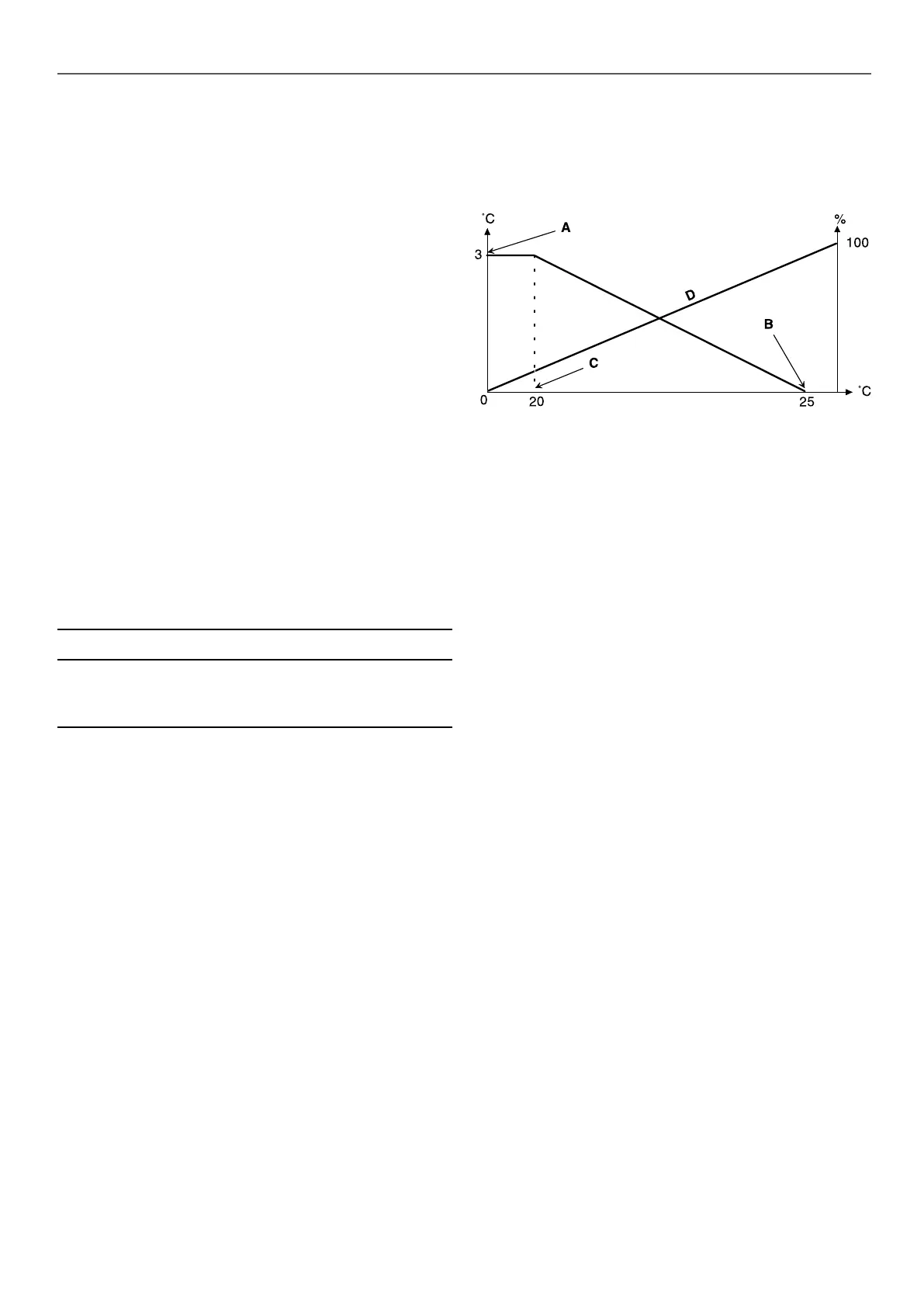

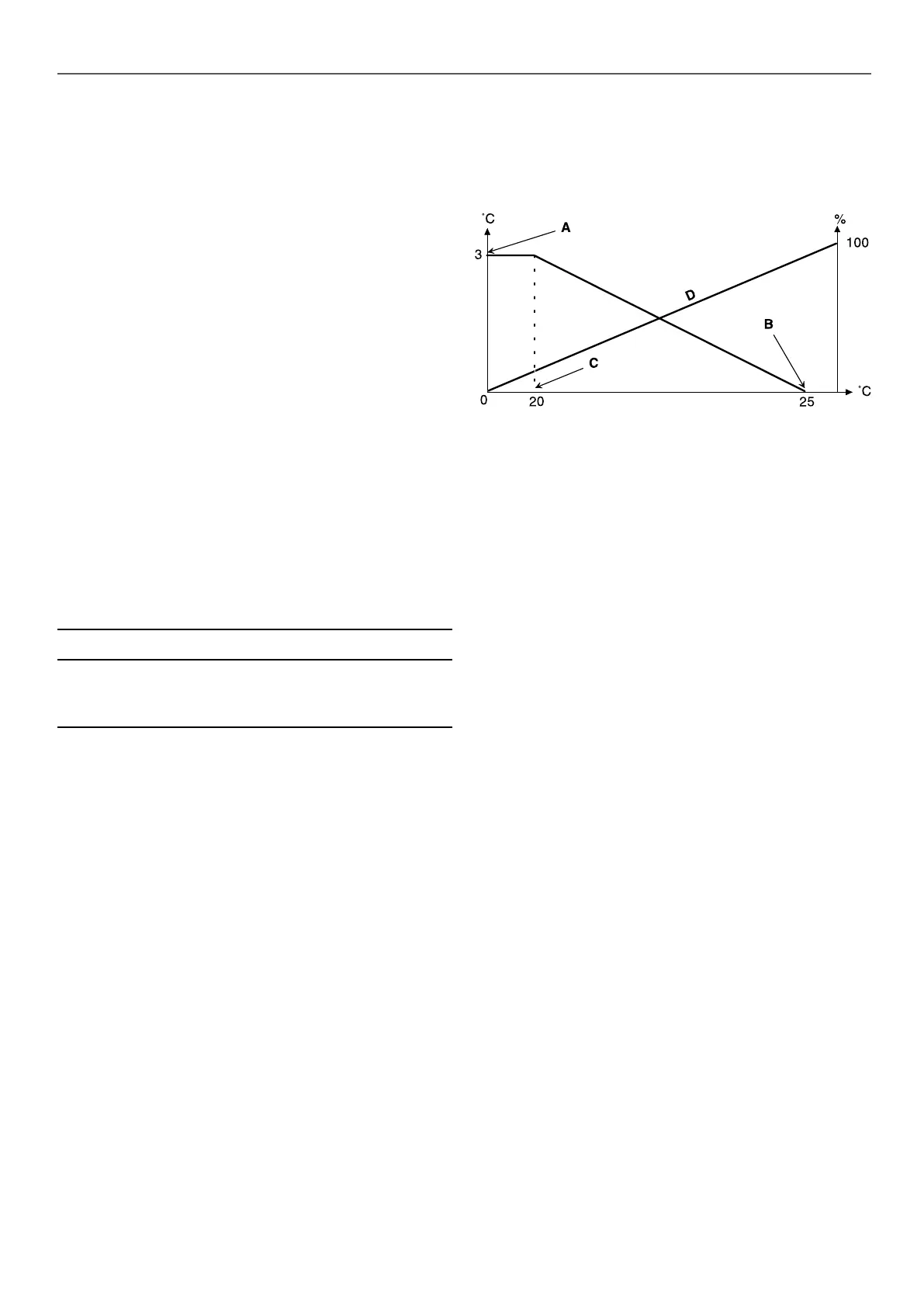

Reset example in Cooling mode for the space temperature

Legend

A: Maximum reset value

B: Space temperature for zero reset

C: Space temperature for maximum reset

D: Building load

8.5 - Ramp loading

The control provides the ramp loading function used to minimise

the rate at which the water temperature changes. The minimum

speed is calculated based on saturated condensing temperature

and saturated suction temperature. Ramp loading sequence can

be enabled by the user (Ramp Loading Select, GEN_CONF –

General Conguration).

8.6 - Capacity control

The unit is tted with oil-free centrifugal compressors with magnetic

bearings. Each circuit may have one or two compressors installed.

Compressors are controlled in such a way in order to provide the

best possible COP. Variable-speed centrifugal compressors exhibit

better performance at part load conditions; therefore, the control

system would normally start both circuits as soon as needed.

The Touch Pilot control adjusts the compressor capacity to keep

the heat exchanger water temperature at its setpoint.

8.7 - Demand limit

The demand limit functionality is used to limit the unit power

consumption whenever possible.

The control allows limitation of the unit capacity:

■ By means of user-controlled volt-free contacts: The unit capacity

can never exceed the limit setpoint activated by these contacts.

The limit setpoints can be modied in the SETPOINT menu.

■ By setting DEM_LIM when the unit is in Network mode.

■ By lag limit set by the master unit (master/slave assembly).

If the unit is not in the Master/Slave assembly, the lag limit value

is equal to 100%.

■ By night capacity limitation. The limit can be modied in the

GEN_CONF menu.

Capacity limitation is expressed in percentage, where a limit value

of 100% means that the unit may run with its full capacity (no

limitation is implemented).

27

Loading...

Loading...