I-120

GH Pump 120 – 16.02.EN

4

H. NON-COMPLIANCE WITH SAFETY

INSTRUCTIONS. Non-compliance with safety

instructions may result in personal injury, property

damage, or unnecessary damage to the pumping unit.

Non-compliance with these safety instructions will also

lead to forfeiture of any and all rights to claims for

damages. Non-compliance, can for example, result in:

Failure of important pumping unit functions.

Failure of prescribed maintenance and servicing

practices.

Hazard to personnel by electrical, mechanical,

and chemical effects.

Hazard to the environment due to leakage of

hazardous substances.

Avoid Possible Non-Compliance. The following

specific safety precautions apply to the pumping unit:

DO NOT exceed maximum discharge pressure

on discharge case (Refer to Table 1).

DO NOT operate pump without fluid to seal or

packing.

DO NOT run pump dry for extended periods of

time (longer than 1/2 hour)

DO NOT run pump against a closed discharge

valve.

DO NOT exceed the Maximum rated speed

(3550 RPM).

A check valve should be installed in the

discharge line.

Pumps assembled by Carver without a motor

will have a Declaration of Incorporation and will

not have a CE mark. When a motor is added, all

guards must be installed, the motor must be CE

marked and the completed machine reviewed

for compliance for applicable EHSRs before a

CE mark is attached.

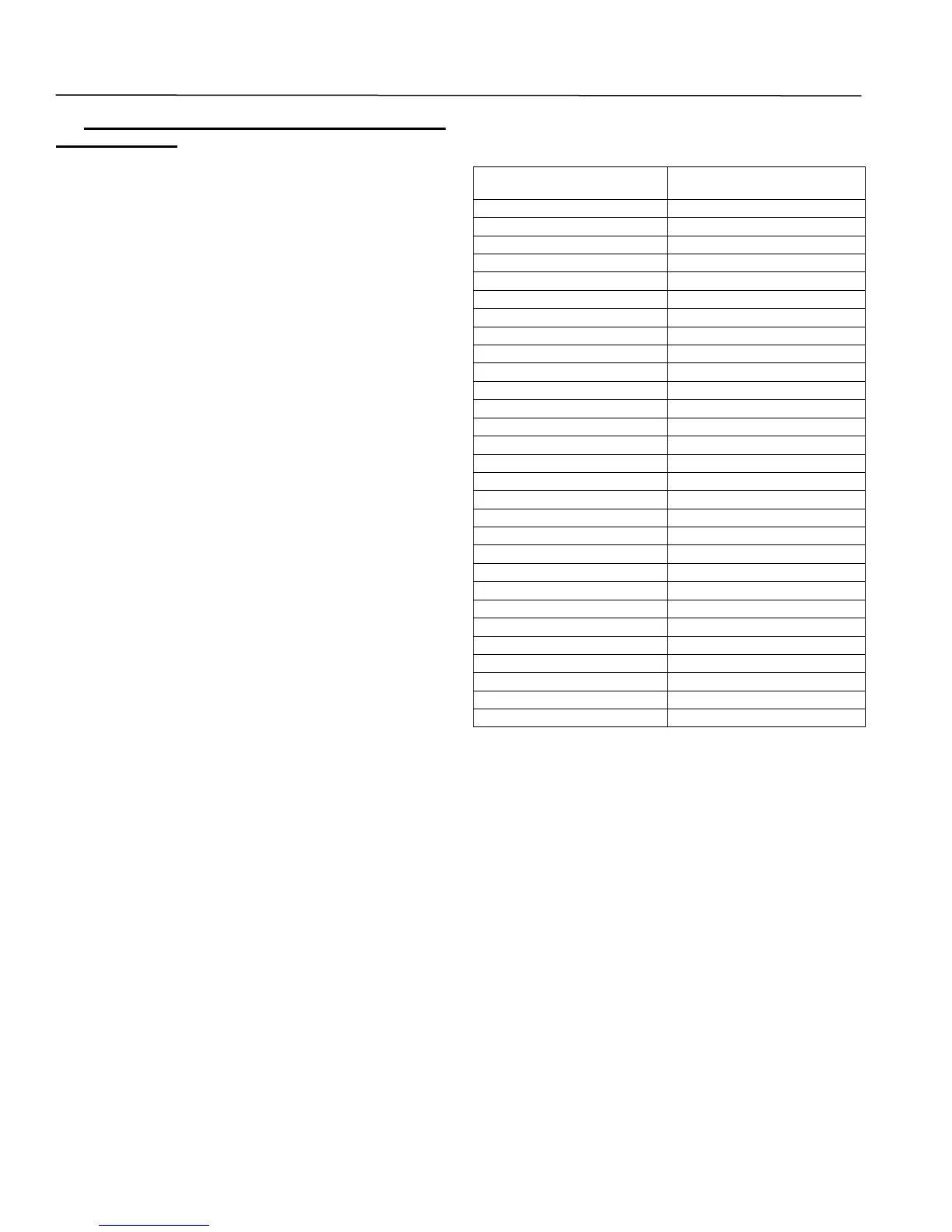

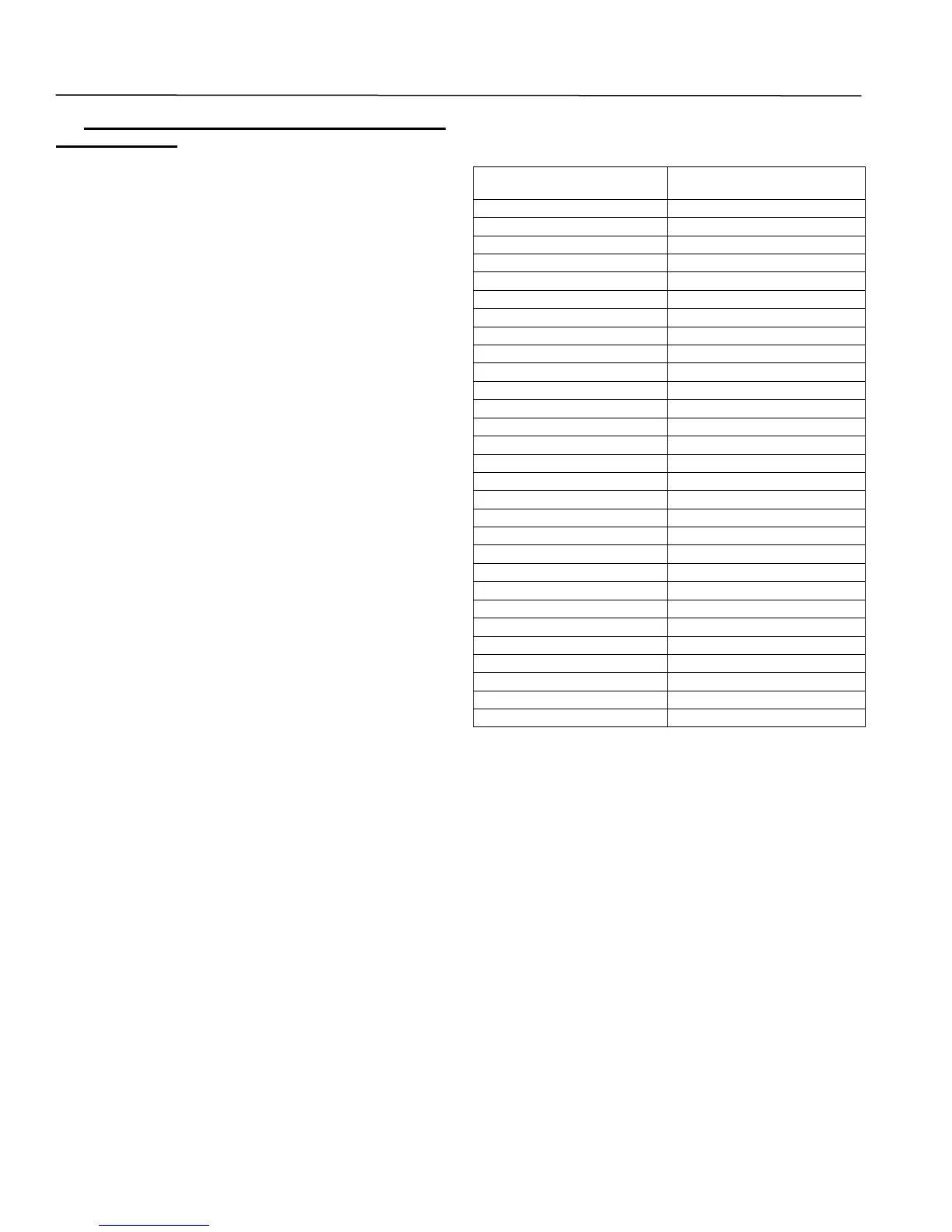

Table 1. Maximum Discharge Pressure on

Discharge Case

Maximum Working Pressure

(PSI) Cast Iron Class 30

III. EQUIPMENT DESCRIPTION.

Standard materials of construction are cast iron and

CD4MCu. Other metallurgies are available, such as

hard iron, monel, hastelloy, etc... Also available is a fully

rubber lined version for abrasive and extremely

corrosive application including the Flue Gas De-

sulfurization (FGD) process with high chlorides.

The bare pump consists of following major parts and

options. Please refer to Figures 9 and 10, assembly

drawings, for the location of parts identified by item

numbers.

Item 1 - Casing. The casing houses the impeller (2)

and consists of the discharge volute, suction cover (9),

back cover (11), and stuffing box. The casing is secured

to the suction cover with capscrews (611) and to the

discharge piping with capscrews and nuts not provided

with the unit.

Loading...

Loading...