I-120

GH Pump 120 – 16.02.EN

10

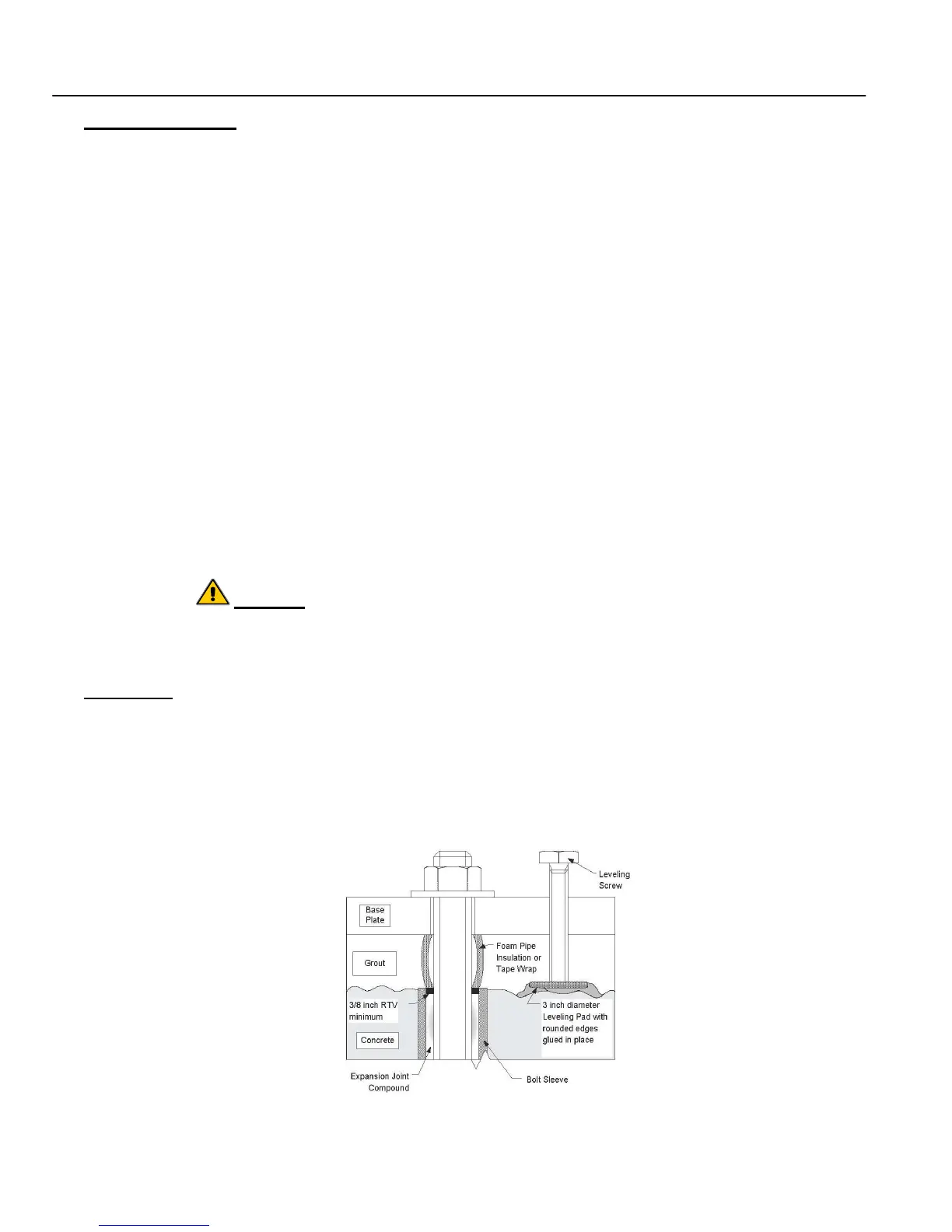

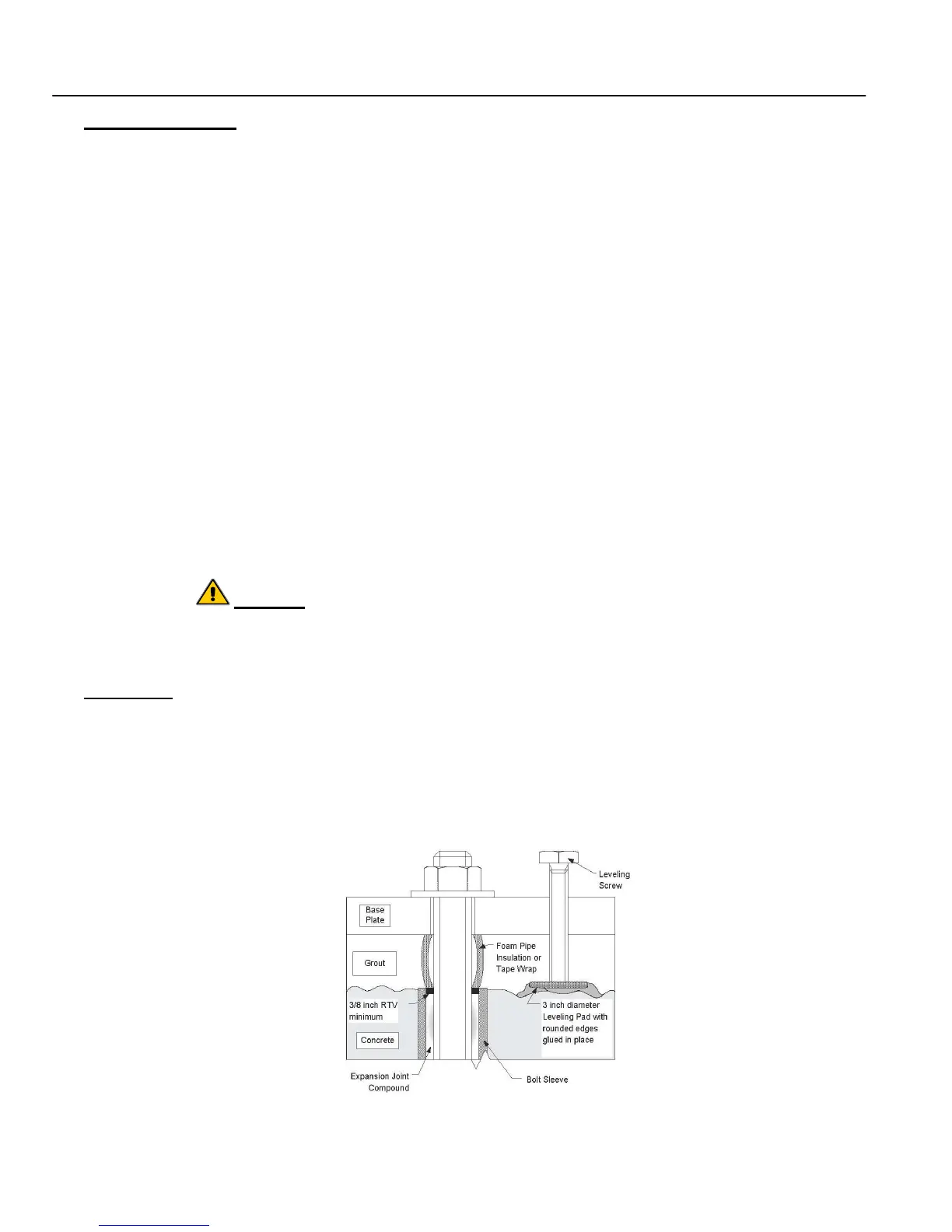

D. LEVELING OF UNIT. When the pump is supplied

complete with motor and base, the unit is assembled at

the factory. Lower unit onto foundation, positioning base

structure so anchor bolts are aligned in middle of holes

in base.

The base should be supported on either rectangular

metal blocks with shims or on metal wedges having a

small taper. The support pieces should be placed close

to the foundation bolts. Refer to Figure 4, Grouting and

Foundation Bolting. Place supports directly under the

part of the base plate, which carries the greatest weight.

Space the supports closely enough to provide uniform

support of the base plate. Adjust the metal supports or

wedges until the shaft is level. Check suction and

discharge flanges of the pump by means of a level.

Make corrections, as necessary, by adjusting the

supports or wedges under the base plate.

The base should be supported on metal shims or metal

wedges placed directly beneath the part of the base

supporting the most weight. The shims or wedges

should be spaced close enough to give support and

stability.

Adjust metal supports or wedges until suction and

discharge flanges are level.

CAUTION

Do not attempt to straighten the base by using

the anchor bolts.

E. GROUTING. After the pumping unit has been

leveled and the alignment is correct, grout the unit to the

foundation using a high-grade, non-shrinking grout, refer

to Figure 4. Proceed grouting using the following

procedure:

Prepare concrete foundations, anchor bolts and leveling

screws according to individual instructions covering

these items.

1. Wax forms heavily with at least three coats of

paste wax. Forms must be substantial and well

braced. All corners, joints, bottoms must be

sealed with silicone caulk for water tightness. All

forms should have a 45° chamfer strip installed

to prevent stress risers.

2. Anchor bolt-free length must be wrapped with

duct seal or electricians plastic tape to prevent

grout from contacting the bare metal. Grout

sticking to the anchor bolt will prevent the

elongation necessary to develop the hold-down

force. Failure to do this will result in broken

anchor bolts.

3. If equipped leveling screws must be greased to

permit removal prior to the final torque.

4. Do not use shim packs as a leveling device

unless it is planned to remove them prior to final

torque application.

5. Leveling screw pads should be a minimum of

1/2" thick with minimum diameter of 3". Corners

of pad must be rounded to approximately 1/8"

radius to prevent stress cracking. Set leveling

screws on the chipped concrete surface. Set the

pad with quick set cement or resin repair

compound. With jacking bolt pads secure and

level, set and level base with leveling screws. If

not equipped with leveling screws use shims to

level.

6. The underside of the standard factory steel

base plate was painted with epoxy grout primer

and should only require proper cleaning. If the

base must be sandblasted, prepare the contact

faces to SSPC-SP 6 Spec. If base cannot be set

within 24 hours of blasting, the underside must

be coated with a compatible rust inhibitive

primer. Tighten foundation bolts loosely. Allow

the grout to fully cure before firmly

tightening the foundation bolts.

Figure 4. Grouting and Foundation Bolting

Loading...

Loading...