I-120

GH Pump 120 – 16.02.EN

18

To lubricate ball bearing (16 and/or 18) use the following

procedure:

CAUTION

Over greasing creates heat and is the cause of

many problems requiring repair. DO NOT

OVER GREASE.

1. Never lubricate ball bearing (16 and/or 18) while

unit is running. If necessary, shut down pumping

unit according to Section IV, Paragraph E.

CAUTION

Do not lubricate bearing with a power grease

gun.

2. Using a hand-operated grease gun on grease

fittings, add approximately one ounce of fresh

grease. With most hand-operated grease guns,

two or three pumps are enough. DO NOT

OVER GREASE. When installing new bearing,

pack new bearing only half full with grease.

Bearing temperature may rise above normal

immediately after lubrication, but should

stabilize within 4 to 8 hours.

B. LUBRICATION OF MOTOR BEARINGS. See

motor manufacturer’s instructions to be sure motor ball

bearings are properly lubricated.

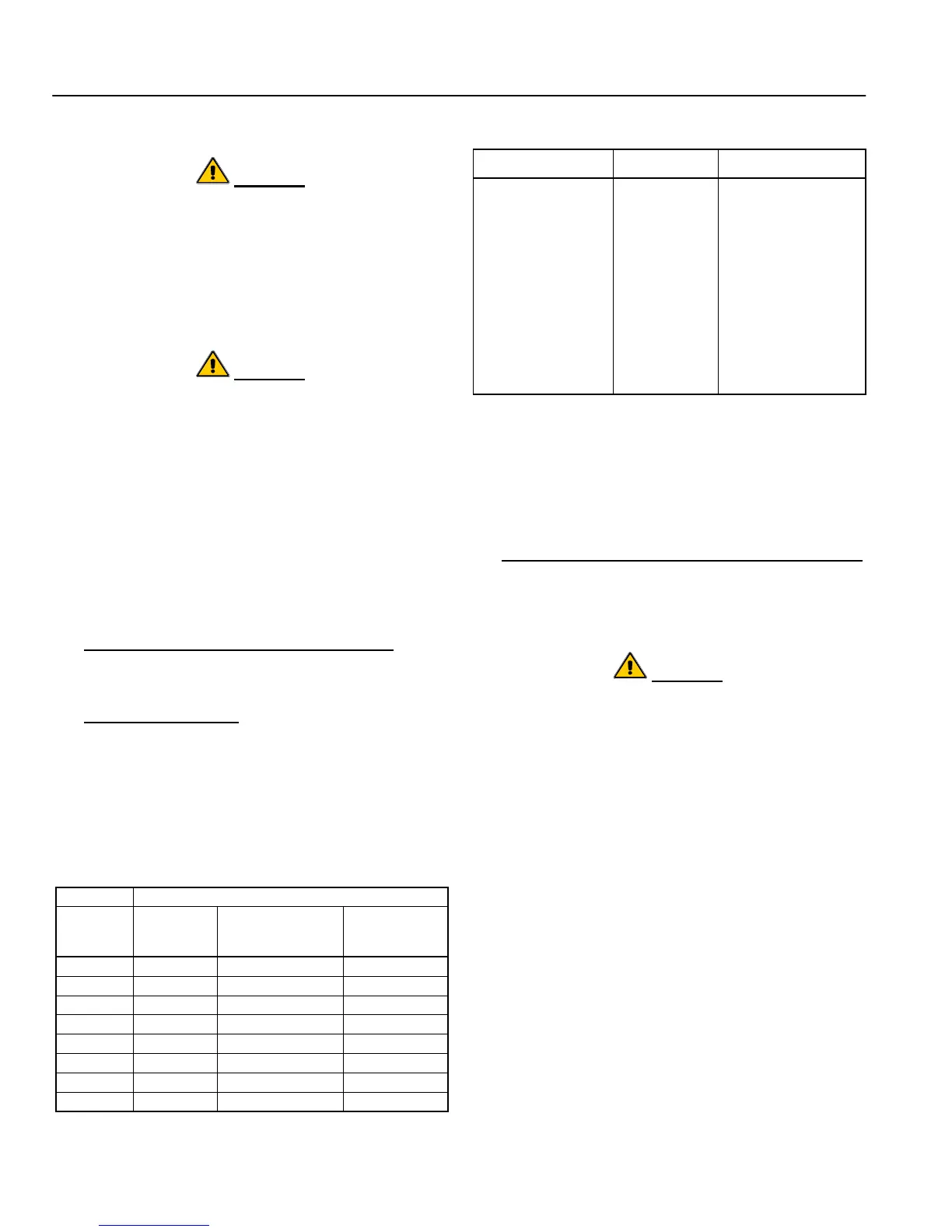

C. TORQUE VALUES. Refer to Table 5,

Recommended Torque Values. Clean and properly

lubricate threads and bearing face of the fastener to

obtain the proper fastener loading from these torque

values. Fasteners should be tightened evenly and in

stages. Refer to your torque wrench manual for the

proper use of your wrench.

Table 5. Recommended Torque Values (ft-lbs)

Steel (or

otherwise noted)

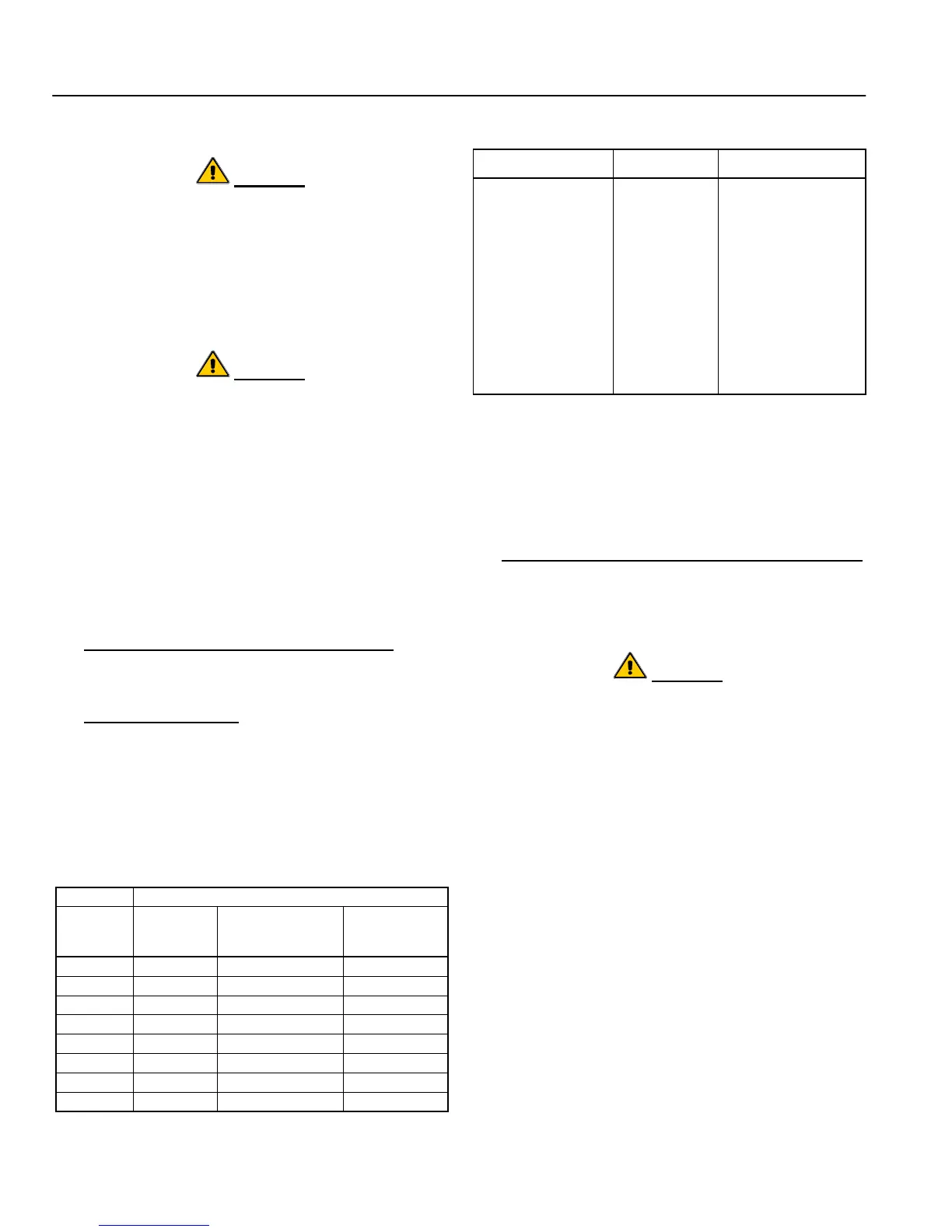

Table 6. Recommended Equipment

Spanner Wrench

Rawhide or

Wood Mallet

Belt Alignment

Gauges

Volt-Amp Meter

Wooden Wedge

Allen Wrench Set

Socket, Open, &

Box Wrench

Set

Rust Solvent

Dow 111

Lubricant

XI. SERVICE AND REPAIR.

Refer to Figures 9 and 10 to locate the pump parts by

item number and parts list Table 8. If a specific sectional

assembly drawing exists for a particular pumping unit

then that drawing should be referred to for service work.

A. PREPARATIONS FOR DISASSEMBLY OF PUMP.

During disassembly, match mark parts so they can be

replaced in their original position. All parts should be

thoroughly cleaned or replaced with new, if necessary.

Sealing faces should be perfectly clean.

CAUTION

Factory authorized parts must be used to safely

maintain your Carver Pump.

NOTE

To avoid damage to O-rings, check to make

sure all parts are free of sharp edges or burrs.

All O-rings, ball bearings, shims, mechanical

seals, lip seals, packing, and gaskets if

disturbed from position should be replaced.

Variations do exist between configurations, not

all parts described in the text may be on your

configuration. Review what variations your

pumping unit has before starting. Parts marked

with * are options or vary by pump.

After prolonged operation, components may not be

easily removed from shaft. In such instances, rust

solvent may be used and suitable extracting tools

applied wherever possible. DO NOT use force under

any circumstances. Refer to Table 6, Recommended

Equipment, for proper tooling during disassembly and

Loading...

Loading...