I-120

GH Pump 120 – 16.02.EN

9

VII. INSTALLATION.

A. LOCATION. The pump assembly should be

located in an area that will permit periodic inspection

and maintenance. Head room and access should be

provided and all units should be installed in a dry

location with adequate drainage. The discharge piping

should be direct with as few elbows and fittings as

possible.

The pump assembly should be installed as close to the

fluid as possible. A short, direct suction pipe can be

used to keep suction losses at a minimum. If possible,

locate the pump so fluid will flow by gravity to the

suction opening. The discharge piping should be direct

with as few elbows and fittings as possible. The total

NPSHA, which includes the suction lift and pipe friction

losses, must be greater than the Net Positive Suction

Head Required (NPSHR) by the pump.

B. HANDLING.

CAUTION

Use a hoist with adequate lifting capacity. See

pump nameplate for weights.

Do not pick up the complete unit by the motor

or the pump shafts or motor lifting eyes.

If the pumping unit slips out of the sling

arrangement, it may cause injury to personnel

and/or damage to the pumping unit.

Moving the unit requires proper preparation and

handling. Always make sure that the pump or the

pumping unit while being moved cannot slip out of the

transport suspension arrangement. Use a sling for

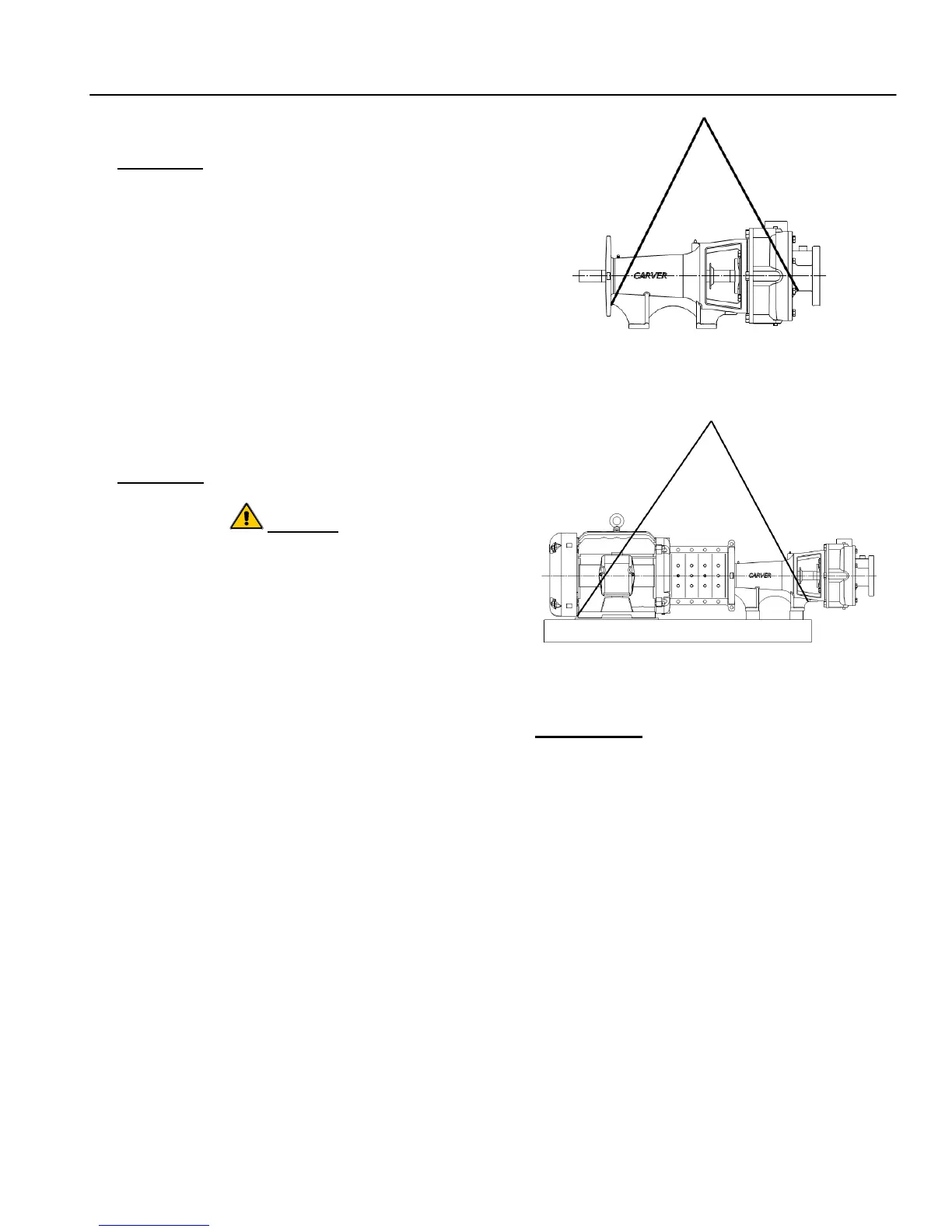

pumps without bases, refer to Figure 2. To lift a

complete unit, a hoist or suitable lifting device should be

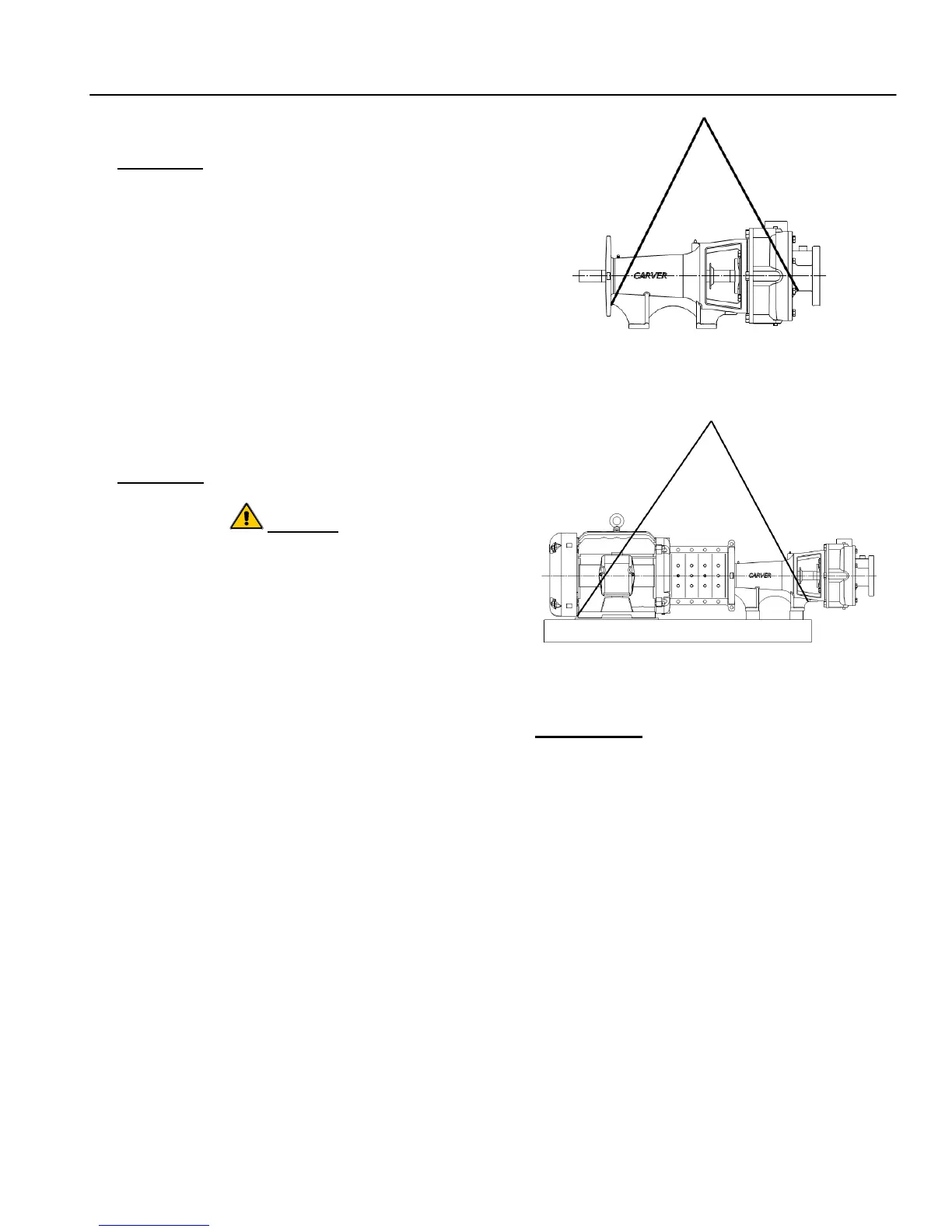

attached to the base, refer to Figure 3. The individual

motor may be lifted using proper eyebolts provided by

the manufacturer, but these should not be used to lift the

assembled unit.

Figure 2. Transport of the Bare Pump

Figure 3. Transport of Coupled Pump

C. FOUNDATION. Make sure that the concrete

foundation has set firmly before placing the unit on it. Its

surface must be truly horizontal and even. The

foundation bolts must be inserted in the baseplate holes.

The foundation should be 3 to 6 inches wider and longer

than the baseplate, have a level surface, and be of

sufficient mass to prevent vibration and form a

permanent rigid support for the unit. The best

foundations are concrete with anchor bolts of adequate

size embedded in the foundation in pipe sleeves having

an inside diameter 2-1/2 times larger than the bolt

diameter. This will allow for accurate positioning of the

unit. Keep the concrete surface clean, yet rough.

Loading...

Loading...