I-120

GH Pump 120 – 16.02.EN

25

and gland flat washers (645) .Install tubing and

tubing fittings, as applicable.

24. Check for smooth shaft rotation. Install splash

guard (*131A) in bearing frame (*19) or

intermediate (*71).

CAUTION

Use a hoist with adequate lifting capacity; refer

to Section VII, Paragraph B, for lifting the

pump.

25. Return pumping unit to installation site. Install

pumping unit on its base and secure to base

with foundation bolts.

26. On frame-mounted pumps, align coupling (*42)

in accordance with Section VII, Paragraph F.

Reconnect coupling. Install coupling guard

(*131).

27. Reconnect piping and gauges, as necessary.

Remove all tags from valves and switches.

Open system valves. Reconnect power supply

to motor.

28. Start pumping unit in accordance with section

IV, Operation.

E. REPLACEMENT OF PACKING. Pumps equipped

with packing have a lantern ring which is located in line

with the flush water connection on the stuffing box. Flow

should be adjusted, typically to 20 to 30 drops per

minute. Flush water pressure should be approximately

70 kPa (10 PSI) more than the pump discharge

pressure to ensure flow of water through the packing.

Use the following procedure when replacing the

packing:

1. Ensure the new packing is of proper type and

size.

a. Typical is five rings, 6mm x 6mm (3/8” x

3/8”).

b. Standard shaft diameter is 32mm (1 1/4”).

c. Pre-cut sets of packing and lantern rings

are available for stock from Carver Pump

Company

2. Stop the pumping unit; refer to Section VIII,

Paragraph E.

3. Carefully bleed off pressure and remove splash

guard (*131A).

4. Remove gland hex nuts (615) and the gland flat

washers (645) on studs (630). Slide back and

remove gland (17) halves.

CAUTION

Do not use system pressure to blow out

(remove) packing.

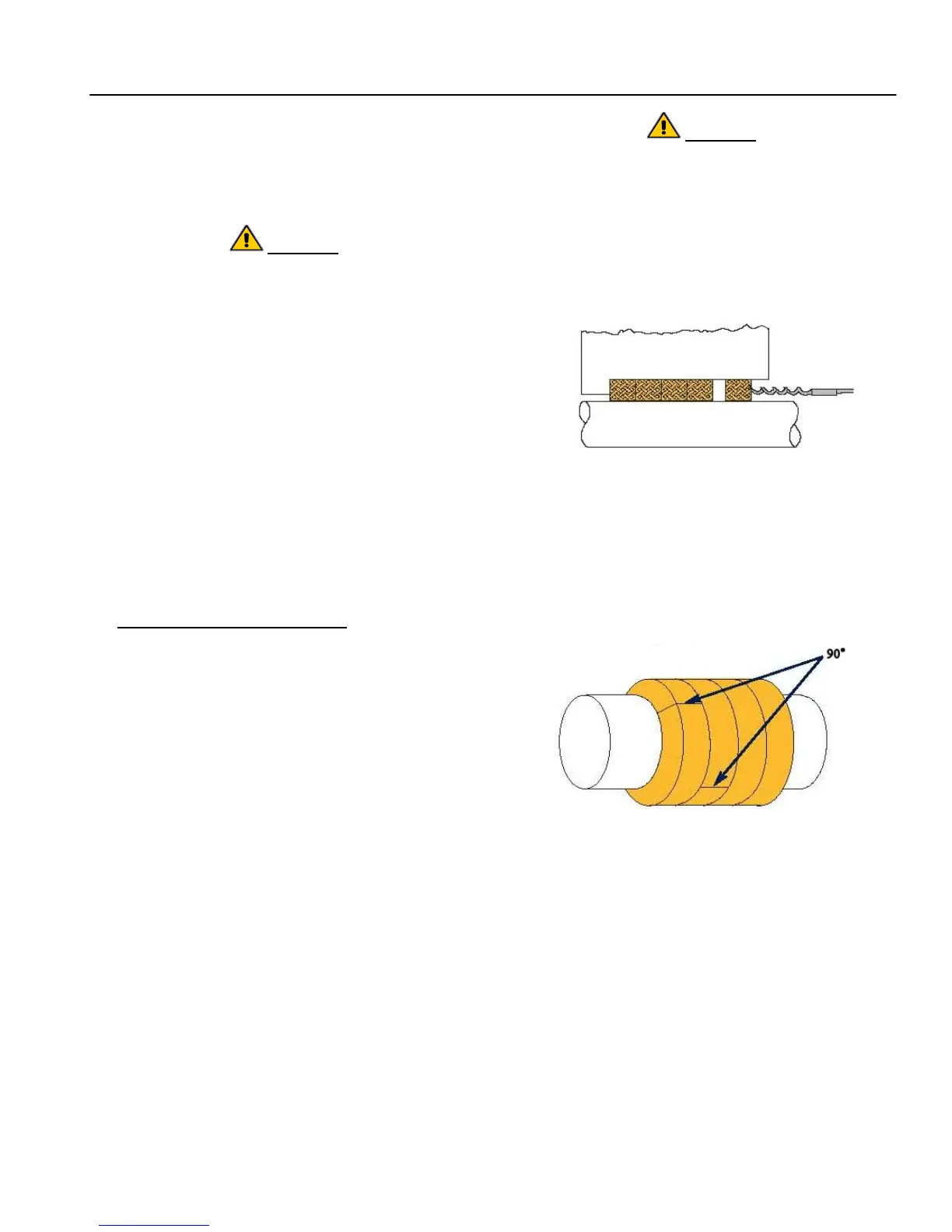

5. Refer to Figure 6; remove all old packing rings

(180) by using the proper size packing removal

hook. The lantern ring (29) will remain on the

shaft (6) and should be slid to near the slinger

(40).

Figure 6. Removing Packing with Hook

6. Check the shaft (6) for nicks and score marks;

repair or replace as necessary.

7. If required, clean the stuffing box bore.

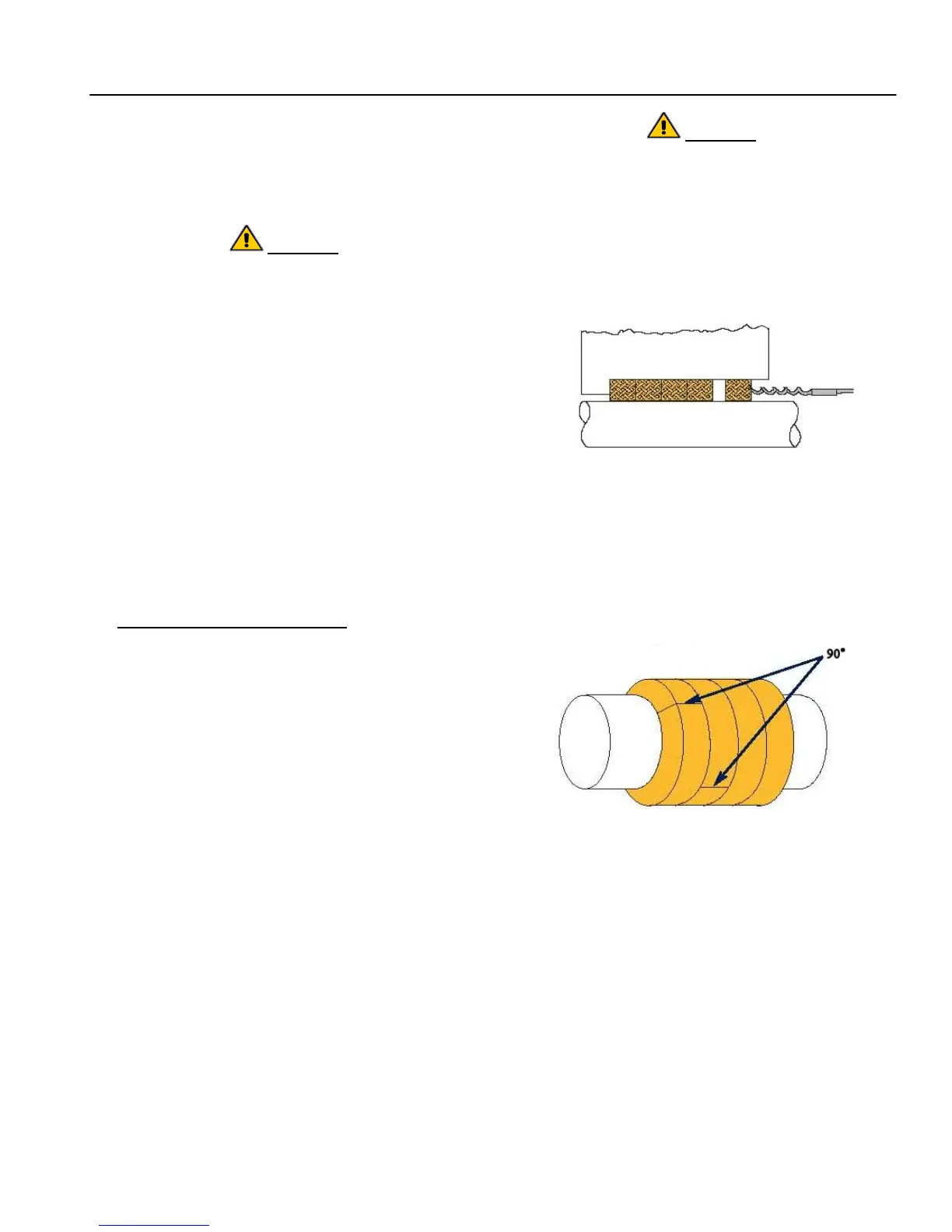

8. Install the first ring of packing (180) with joint at

approximately the 1 o’clock position (30° right of

vertical). Refer to Figure 7 for packing

alignment.

Figure 7. Packing Alignment

9. Twist the ring of packing (180) slightly in an “S”

shape and place it around the shaft (6).

10. Seat packing (180) firmly against bottom of

stuffing box using the gland (17).

11. Repeat procedure as described in Steps 8

through 10. Packing (180) ring joints should be

staggered 90° apart.

12. Install enough rings (typically 2) until lantern ring

will align with flush water port.

13. Slide lantern ring (29) back up shaft (6) into

position.

Loading...

Loading...