ERVICE

S

23

208743 Rev. 1

5.4-4 Cylinder Inspection

• Inspect all components for nicks or burrs. Minor nicks

or burrs can be removed with 400 grit emery cloth.

NOTE: Minor nicks are those that will not bypass oil

under pressure. If nicks cannot be removed with emery

cloth, replace the part.

• Inspect the outside of the shell for deformities that could

weaken the shell’s performance when under pressure.

Replace if necessary.

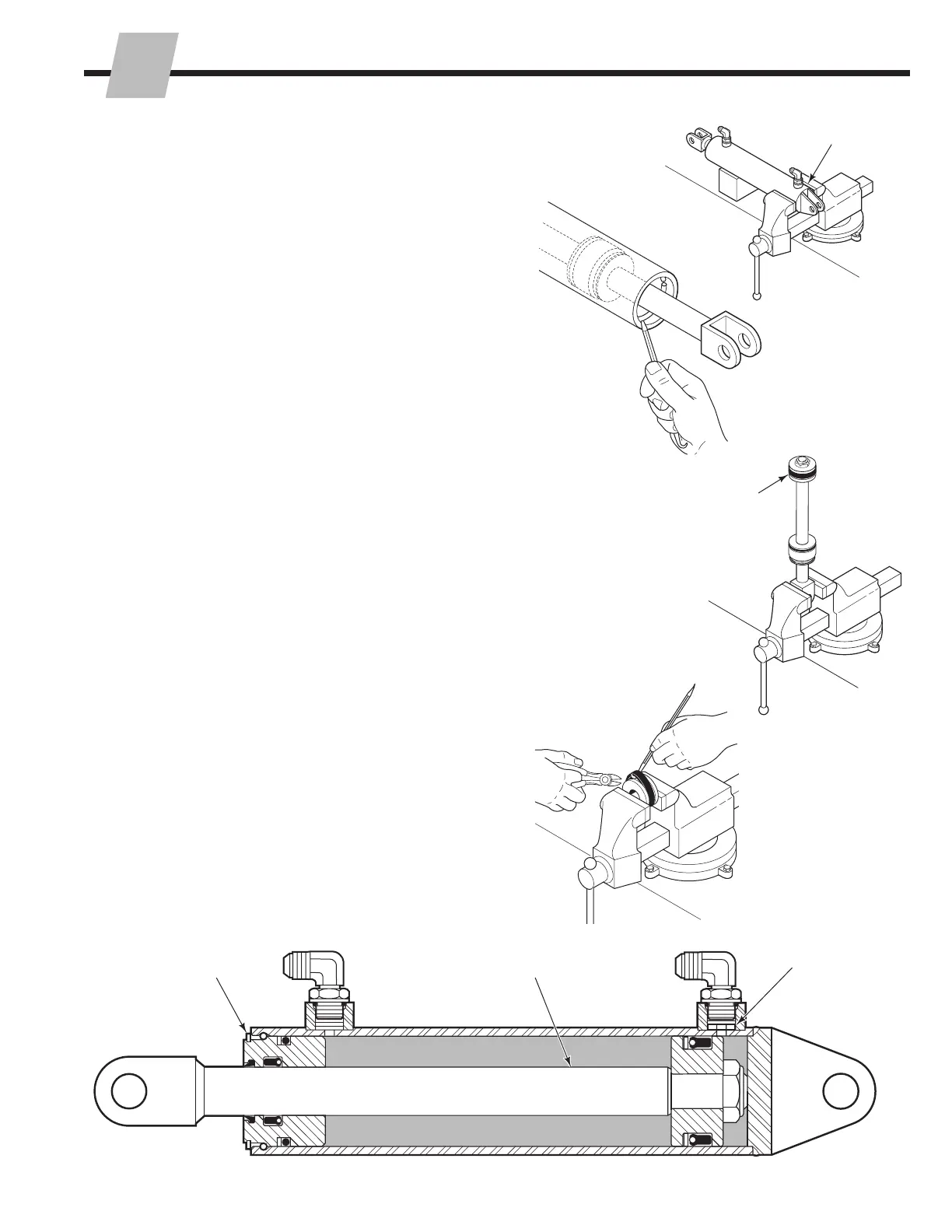

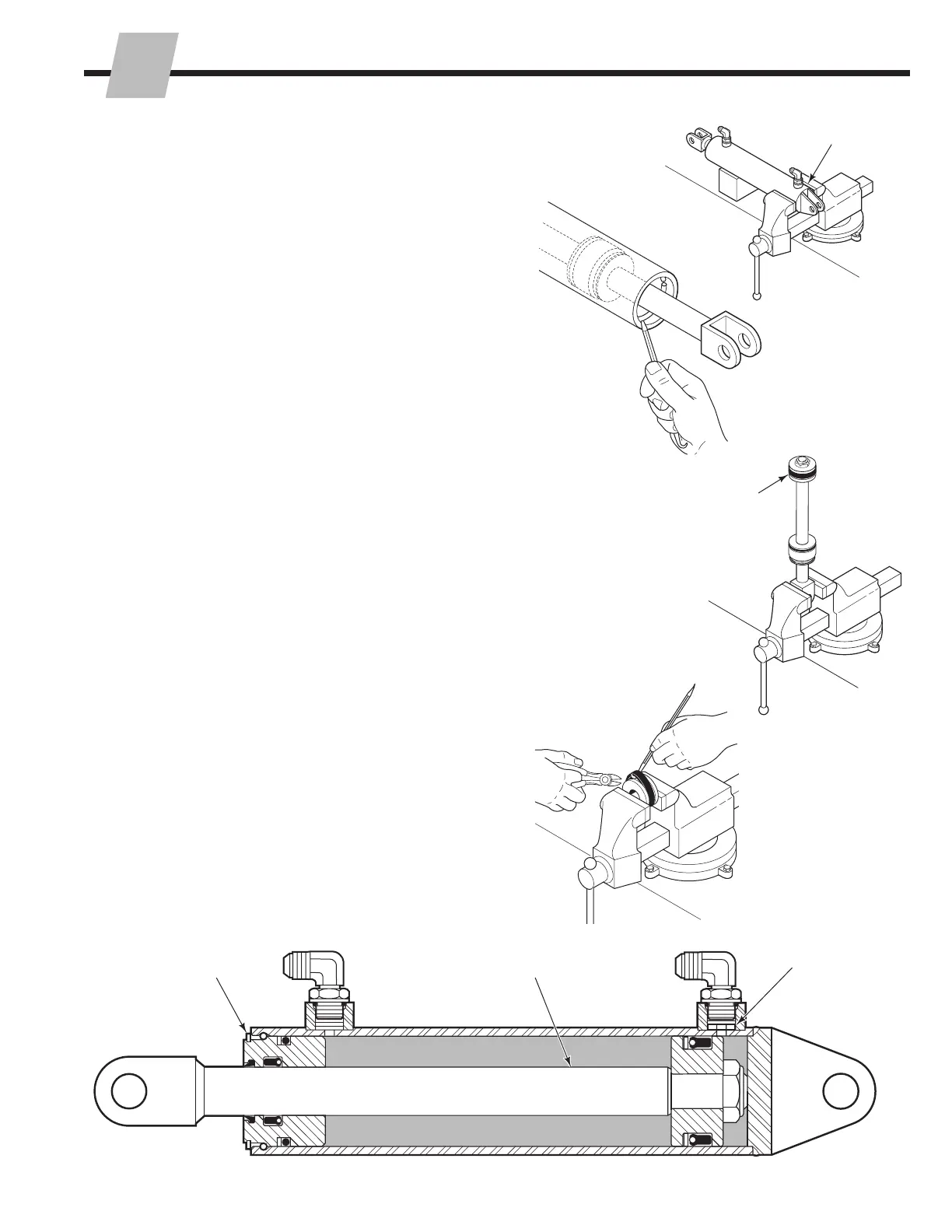

5.4-3 Cylinder Disassembly

1 Clamp the cylinder in a soft-jawed vise. Clamp lightly

on the base end only.

2 Position the cylinder rod in the fully extended position.

Remove the spiral snap rings from the retainer. See the

illustration below.

3 Tap the retainer into the shell approximately 2 in.

(50 mm). Remove the retaining ring by prying one end

up and working the ring out of the groove.

Service Tool Kit 674424 includes two double-ended

brass tools that make seal and ring removal easy and

won’t damage the cylinder components with dents or

scratches.

CAUTION: Do not scratch the cylinder bore.

4 Remove the rod assembly from the cylinder. See the

illustration below.

5 Clamp the rod assembly in a soft-jawed vise or between

two blocks of wood. Never clamp directly on the rod

sealing surface. Remove the nut fastening the piston to

the rod. Remove the piston and retainer.

6 Place the piston or retainer in the vise to remove the

seals. Pry the seals up with a brass tool. Cut the seals

to remove.

CAUTION: Do not scratch the seal grooves.

2

4

Restrictor

Washer

6

1

5

3

Loading...

Loading...